Test method for influence of coalbed methane extraction on coal seam roof deformation under non-uniformly distributed load

A technology of coal seam roof and deformation test, which is applied in the application of stable tension/pressure to test the strength of materials, preparation of test samples, measurement devices, etc., and can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0029] A method for testing the influence of coalbed methane extraction on the deformation of a coal seam roof under a non-uniform load, comprising the following steps:

[0030] Step 1, making the test device.

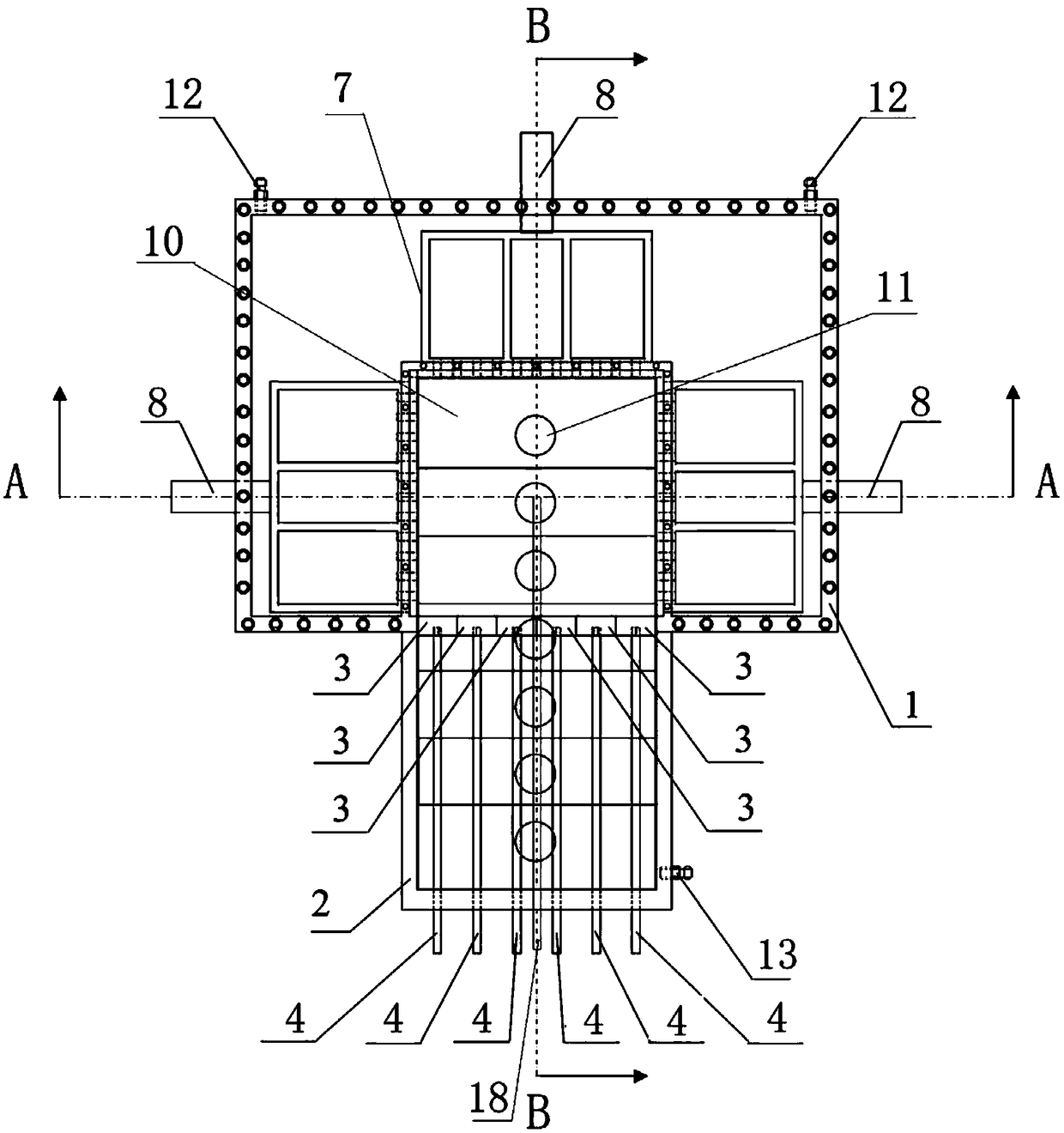

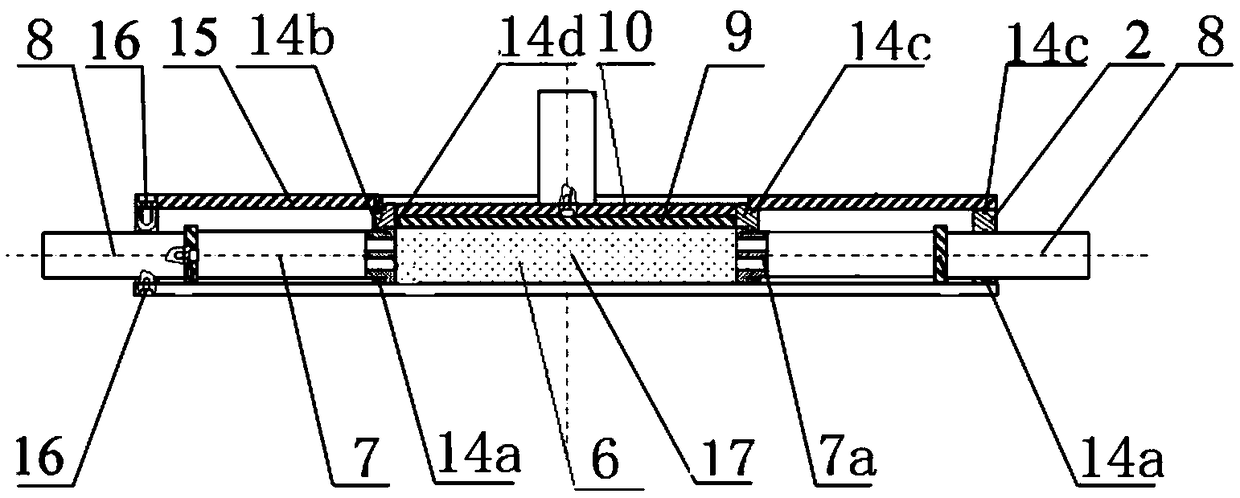

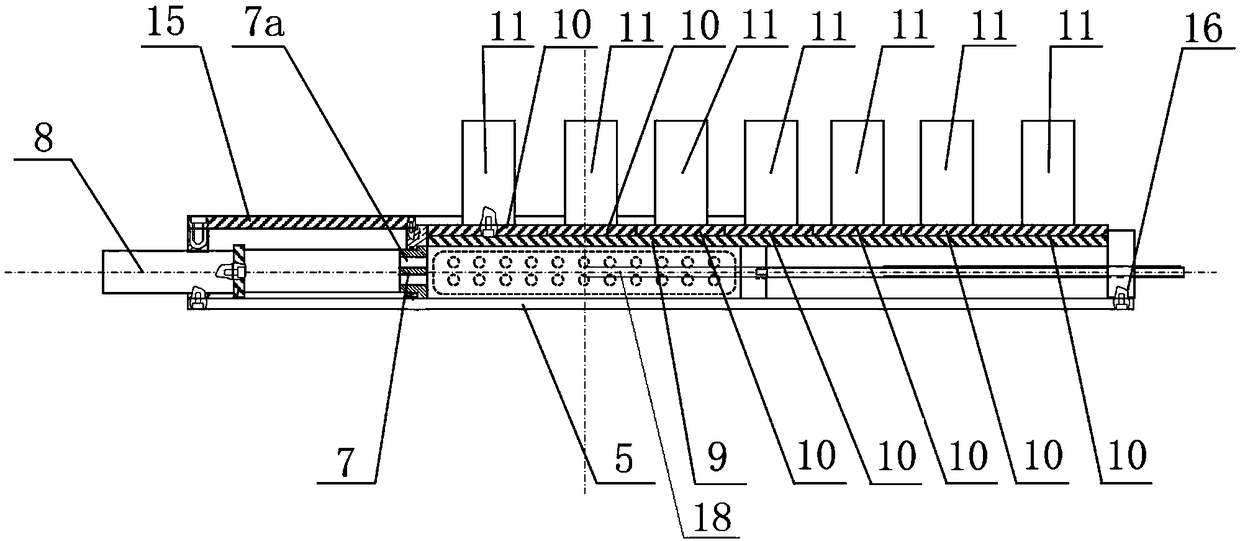

[0031] combine figure 1 — image 3 As shown, the test device is mainly composed of a sealed cavity 1, a transparent box 2, a front pressure plate 3, a front pressure rod 4, a side pressure plate 7, a side pressure rod 8, an upper backing plate 9, an upper pressure plate 10, and an upper pressure rod 11.

[0032] The sealed cavity 1 is in the shape of a "concave" as a whole, and the notch of the sealed cavity 1 faces forward.

[0033] A transparent box 2 with the same height and width as the notch is arranged in front of the sealed cavity 1 . The rear portion and the top of the transparent box 2 are open and just connected with the notch. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com