Mechanical equipment angle detection device

A technology of angle detection and mechanical equipment, which is applied in angle/taper measurement and other directions, can solve the problems of low meshing accuracy of nylon gears, difficulty in placing nylon gears, and sensor damage, etc., achieving low cost, simple structure, and stable angles precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

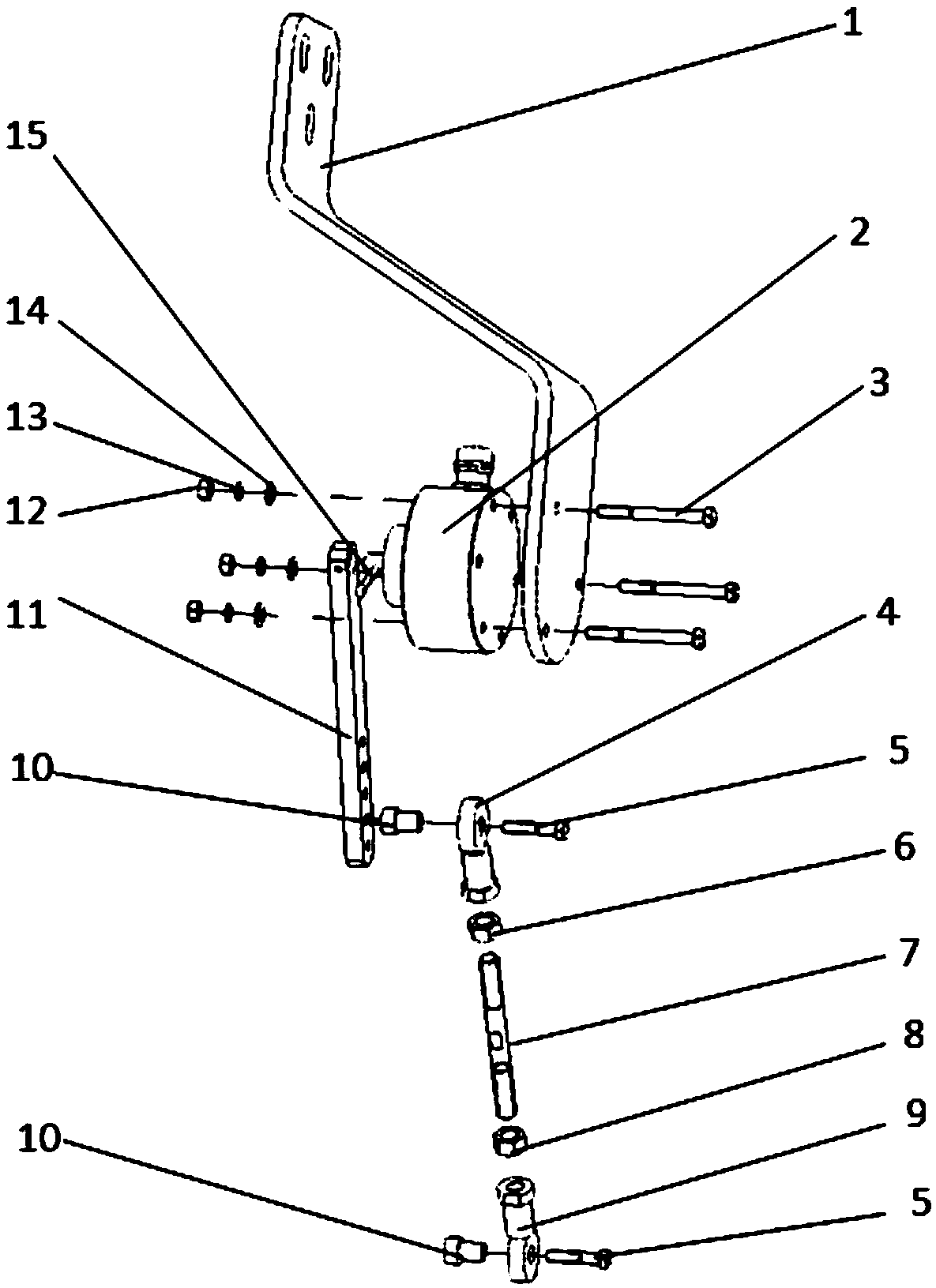

[0032] The present invention will be further described below in conjunction with specific examples.

[0033] Such as figure 1 As shown, it is a mechanical equipment angle detection device, including a bending plate 1, an angle sensor 2, a mounting bolt 3, a first rod end joint bearing 4, a bolt 5, a tightening nut 6 (forward rotation), a pull rod 7, a screw Tight nut 8 (anti-rotation), second rod end joint bearing 9, spacer 10, connecting rod 11, nut 12, flat washer 13, spring washer 14, cotter pin 15.

[0034] Assuming that the second device rotates around the first device, the angle sensor 2 is installed on the bending plate 1 through the mounting bolt 3 and the nut 12, and a flat washer 13 and a spring washer 14 are arranged between the nut 12 and the angle sensor 2 in sequence; the bending plate 1 The other end is fixedly installed on the first device; the angle sensor mandrel is connected to one end of the connecting rod 11, the other end of the connecting rod 11 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com