Pneumatic hydrodynamic linkage spray dust reduction device for blasting working face

A wind and water linkage, spray dust reduction technology, applied in the direction of safety devices, dust prevention, mining equipment, etc., can solve the problems of on-site operating environment and personnel health adverse effects, high procurement and maintenance costs, and many flying rocks on the working face, etc. The effect of air purification time, improvement of dust suppression effect, and reduction of dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

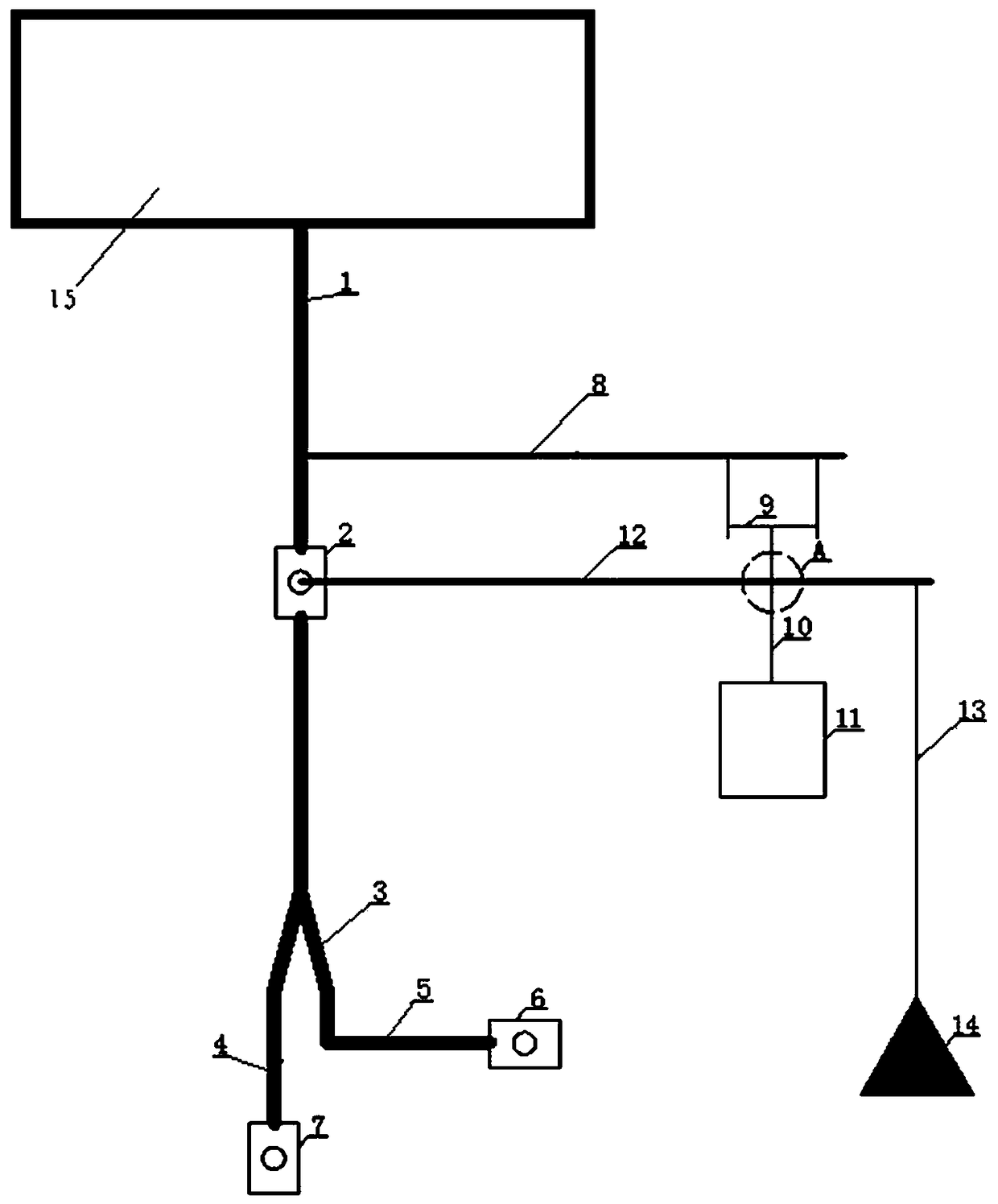

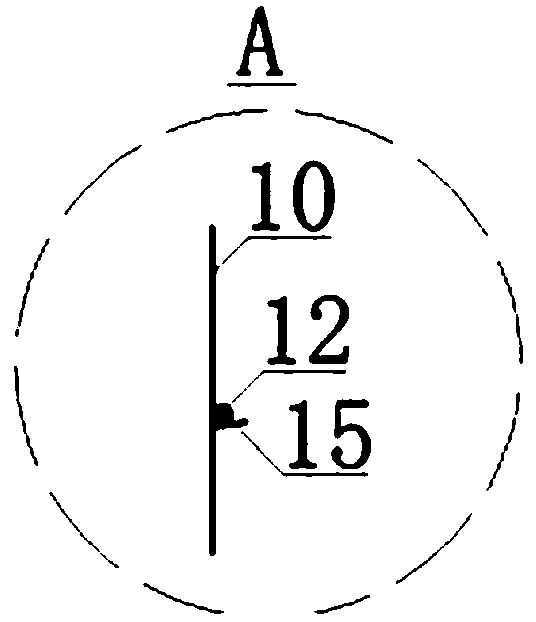

[0010] A wind-shui linkage spray dust suppression device for blasting working face, such as figure 1 , figure 2 As shown, it includes a water pipe 1 connected to a water purification curtain device 15. A bracket 8 is fastened to the water pipe 1 horizontally. The free end of the bracket 8 is hinged to a vertically arranged connecting rod 10 through a rotating shaft 9. The connecting rod A hook 15 is set on 10, and an iron plate 11 is set at the lower end of the connecting rod 10; a quick valve 2 is installed on the water pipe below the bracket 8. The valve stem of the quick valve 2 and a horizontally arranged rotating rod 12 In linkage, the rotating rod 12 passes through the hook 15 and is positioned by it. The free end of the rotating rod 12 is hung with a heavy hammer 14 through a wire rope 13; the lower end of the water pipe 1 is respectively connected with a Y-shaped tee 3 An air inlet pipe 4 and a water inlet pipe 5, the ends of the air inlet pipe 4 and the water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com