Pneumatic precipitation method and used precipitation device

A pneumatic and gas technology, used in construction, infrastructure engineering and other directions, can solve the problems of abandoned wells, high costs, and high well pipe construction costs, and achieve the effects of low construction cost, low equipment maintenance cost, and strong precipitation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

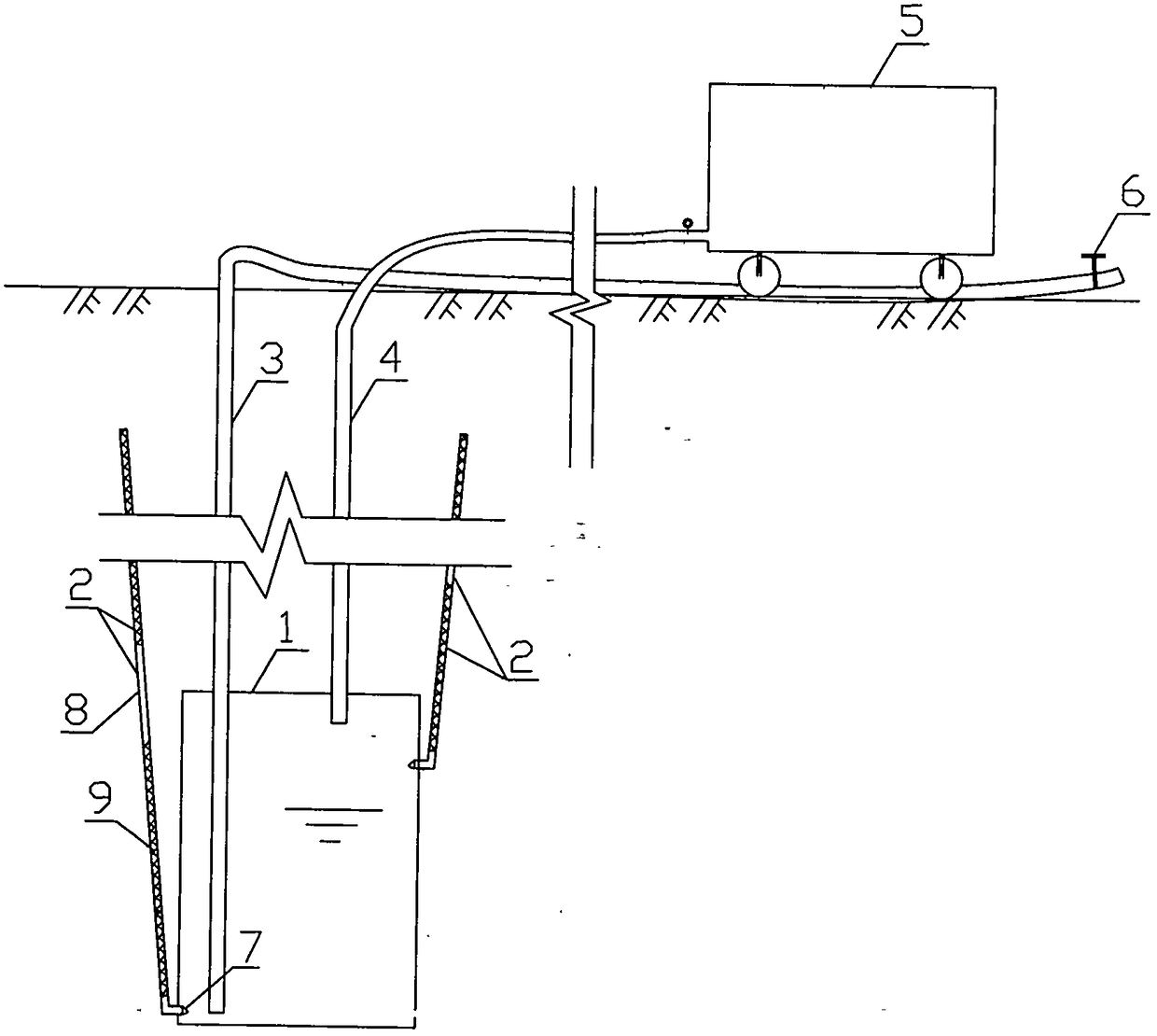

[0015] As an embodiment of the present invention, combined with figure 1 The mechanism and implementation method of the aerodynamic precipitation method and the aerodynamic precipitation device used in the present invention are introduced in detail. First, combine figure 1 The structure and working mechanism of the pneumatic precipitation device of the present invention are introduced. Such as figure 1 Shown, pneumatic precipitation device of the present invention comprises water storage tank (1), underground water collector (2), water outlet pipe (3), air delivery pipe (4), five parts of air delivery device (5), wherein water storage tank (1) is a container buried deep in the soil, and the groundwater collector (2) includes two parts, a water flow channel (8) and a filter membrane (9), wherein the water flow channel (8) is connected with the water storage tank (1), and the filter The membrane (9) is wrapped on the outside of the water flow channel (8), the groundwater coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com