Hydraulic lifting process for installation of furnace shell during blast furnace overhaul

A technology of hydraulic lifting and blast furnace shell, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of heavy overall weight and difficulty in hoisting, achieve the effects of improving stability and flexibility, speeding up progress, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

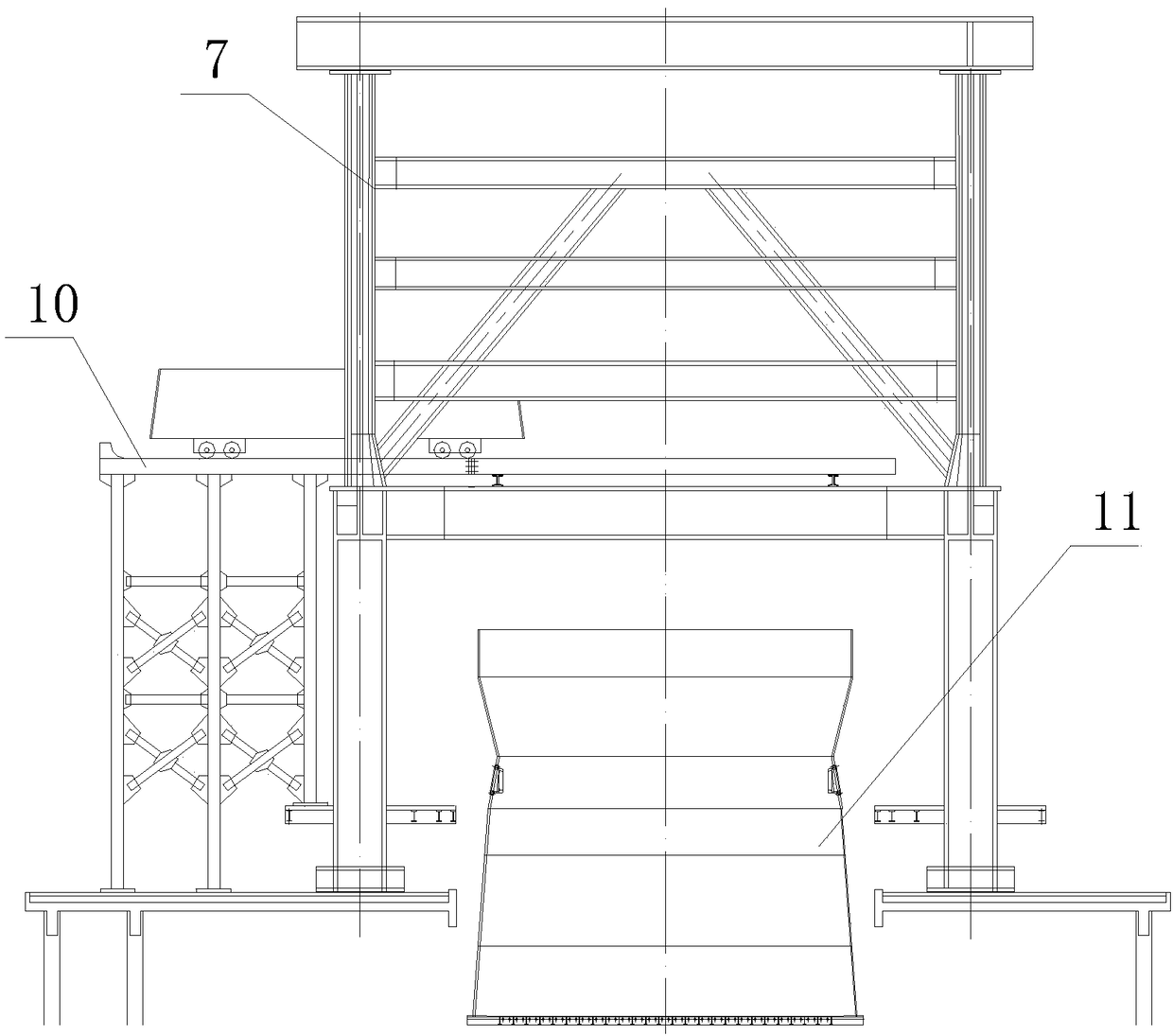

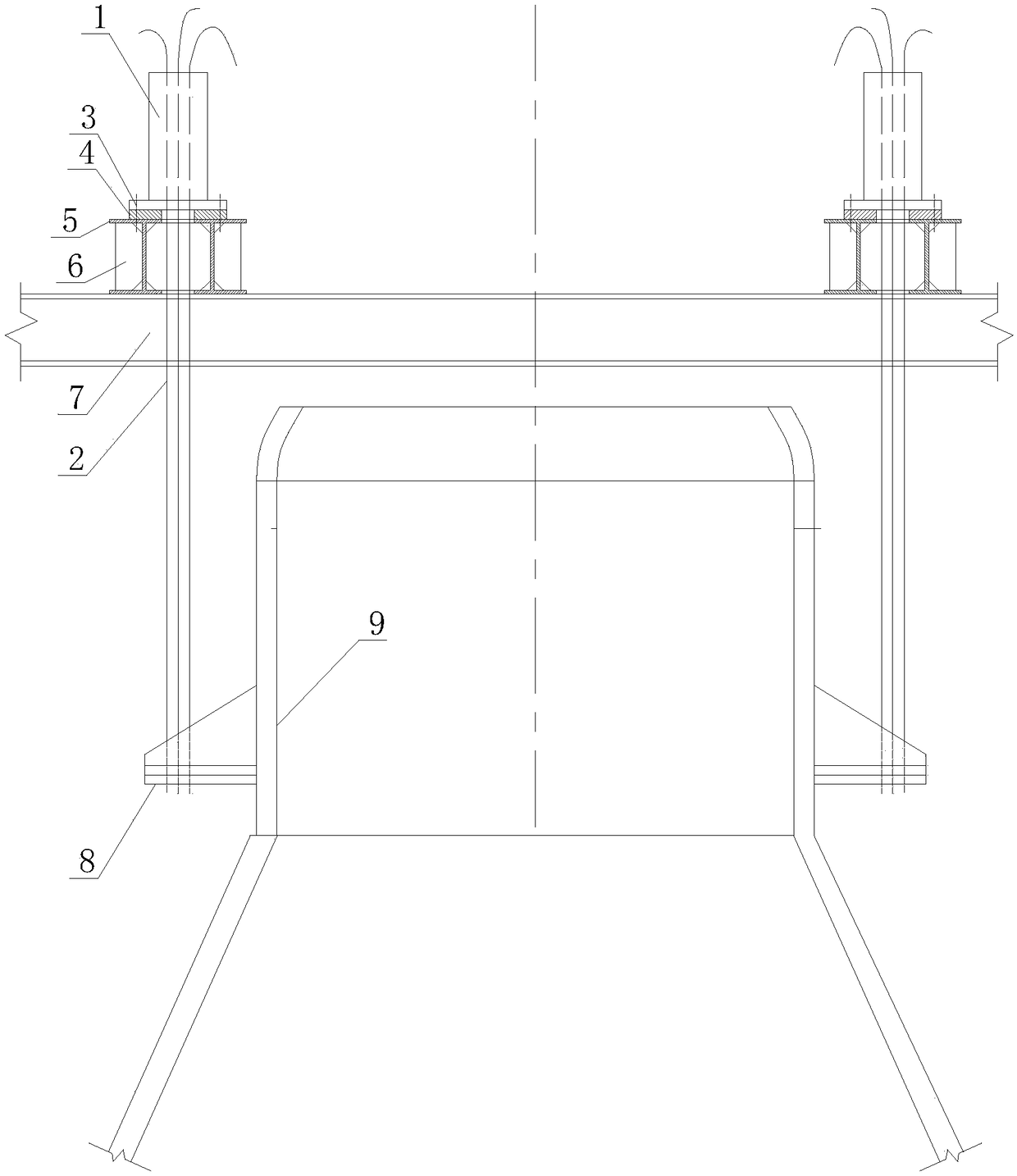

[0023] Such as figure 1 and figure 2 As shown, the present invention is a hydraulic lifting process for the installation of the blast furnace shell during the overhaul of the blast furnace, which is applied to the installation of the blast furnace shell during the overhaul of the blast furnace. During the overhaul of the blast furnace, the original furnace body frame 7 of the blast furnace is retained and set The temporary carriage platform 10 divides the blast furnace shell to be installed into an upper furnace shell 9 and a lower furnace shell 11. The lower furnace shells 11 are installed sequentially from bottom to top with each belt furnace shell. After the installation of the lower furnace shells 11 is completed, the upper furnace shells 9 are installed in a top-to-bottom sequence. For the inversion of each belt furnace shell, considering the structure of the furnace body frame 7 and the layout of the blast furnace casthouse, the temporary carriage platform 10 is genera...

Embodiment 2

[0031] Such as figure 1 and figure 2 As shown, take a certain steel with a 2500m 3 Taking a high-level blast furnace as an example, a hydraulic lifting process for the installation of the blast furnace shell during the overhaul of the blast furnace is applied to the installation of the blast furnace shell during the overhaul of the blast furnace. Temporary carriage platform 10 is set at the position, and the blast furnace shell to be installed is divided into upper furnace shell 9 and lower furnace shell 11. The upper furnace shell 9 is divided into 9-15 bands from bottom to top, and the lower furnace shell 11 is divided into 1-8 belts, the total weight of the upper furnace shell 9 is about 200t, and each belt furnace shell is translated from the temporary carriage platform 10 into the furnace body frame 7 and then hoisted and installed. The 1- The 8 belts all enter the furnace body frame 7 from the temporary carriage platform 10 in a complete circle, and are hoisted and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com