Preparation method of flame-retardant and high-temperature thermal shrinkage pipe

A heat-shrinkable tube and high-voltage-resistant technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor physical and mechanical properties and application limitations, and achieve excellent voltage resistance, strong anti-interference, and high-quality materials Good compatibility between

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment relates to a flame-retardant and high-pressure heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube is composed of the following raw materials in parts by weight:

[0042] 64 parts of styrene-isoprene-styrene block copolymer;

[0043] 24 parts of maleic anhydride grafted EPDM rubber;

[0044] 8 parts of polyphenylene ether resin;

[0045] 5 parts red stone fat;

[0046] 10 parts of perovskite tailings powder;

[0047] 2 parts of tri(butoxyethyl) phosphate;

[0048] 0.6 parts of aluminum-zirconium double metal coupling agent;

[0049] 1.5 parts of compound crosslinking agent;

[0050] 1 part of compound anti-aging agent.

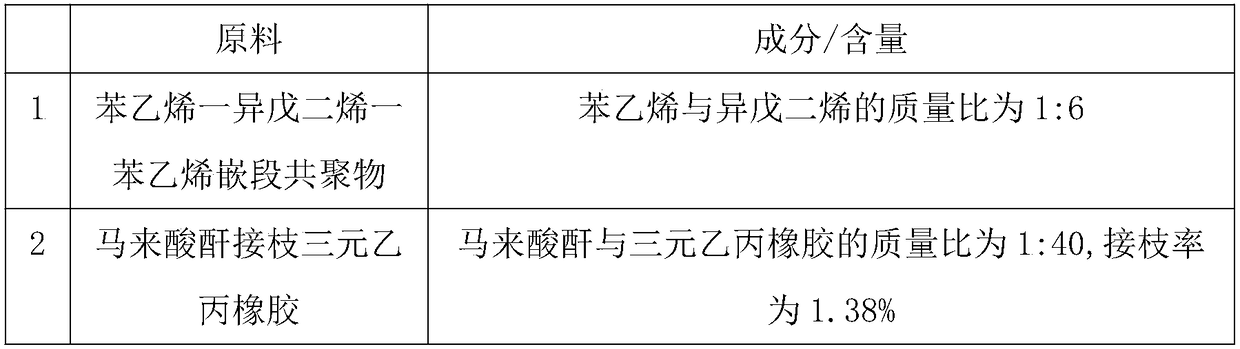

[0051] The selection and production of styrene-isoprene-styrene block copolymer, maleic anhydride grafted EPDM rubber, compound crosslinking agent and compound anti-aging agent in this example are shown in Table 1 below :

[0052] Table 1

[0053]

[0054]

[0055] The preparation method of the he...

Embodiment 2

[0059] This embodiment relates to a flame-retardant and high-pressure heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube is composed of the following raw materials in parts by weight:

[0060] 68 parts of styrene-isoprene-styrene block copolymer;

[0061] 26 parts of maleic anhydride grafted EPDM rubber;

[0062] 9 parts of polyphenylene ether resin;

[0063] 5.5 parts of red stone fat;

[0064] 11 parts of perovskite tailings powder;

[0065] 2.3 parts of tris (butoxyethyl) phosphate;

[0066] 0.65 parts of aluminum-zirconium double metal coupling agent;

[0067] 1.8 parts of compound crosslinking agent;

[0068] Compound anti-aging agent 1.4 parts.

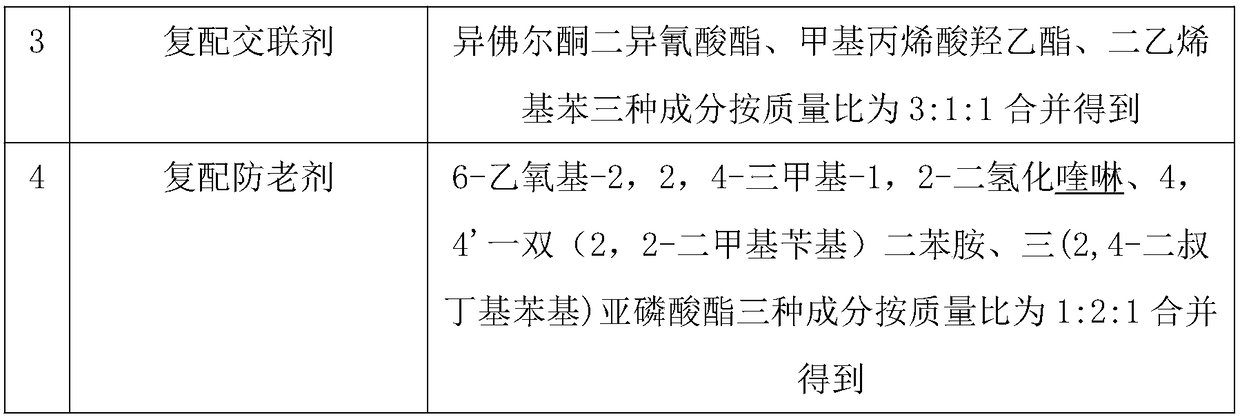

[0069] The selection and production of styrene-isoprene-styrene block copolymer, maleic anhydride grafted EPDM rubber, compound crosslinking agent and compound anti-aging agent in this example are shown in Table 2 below :

[0070] Table 2

[0071]

[0072]

[0073] The preparation meth...

Embodiment 3

[0077] This embodiment relates to a flame-retardant and high-pressure heat-shrinkable tube and a preparation method thereof. The heat-shrinkable tube is composed of the following raw materials in parts by weight:

[0078] 72 parts of styrene-isoprene-styrene block copolymer;

[0079] 28 parts of maleic anhydride grafted EPDM rubber;

[0080] 10 parts of polyphenylene ether resin;

[0081] 6 parts red stone fat;

[0082] 12 parts of perovskite tailings powder;

[0083] 2.5 parts of tris (butoxyethyl) phosphate;

[0084] 0.7 parts of aluminum-zirconium double metal coupling agent;

[0085] 2 parts of compound cross-linking agent;

[0086] Compound anti-aging agent 1.5 parts.

[0087] The selection and production of styrene-isoprene-styrene block copolymer, maleic anhydride grafted EPDM rubber, compound crosslinking agent and compound anti-aging agent in this example are shown in Table 3 below :

[0088] table 3

[0089]

[0090] The preparation method of the heat-shr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com