Preparation method of amorphous sugammadex sodium

A sugammadex sodium and amorphous technology, which is applied in the field of preparation of amorphous sugammadex sodium, can solve problems such as insoluble matter, unqualified product clarity, difficulty in meeting the quality requirements of raw materials, etc., and achieve stable product quality , improve quality and safety, and reduce production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

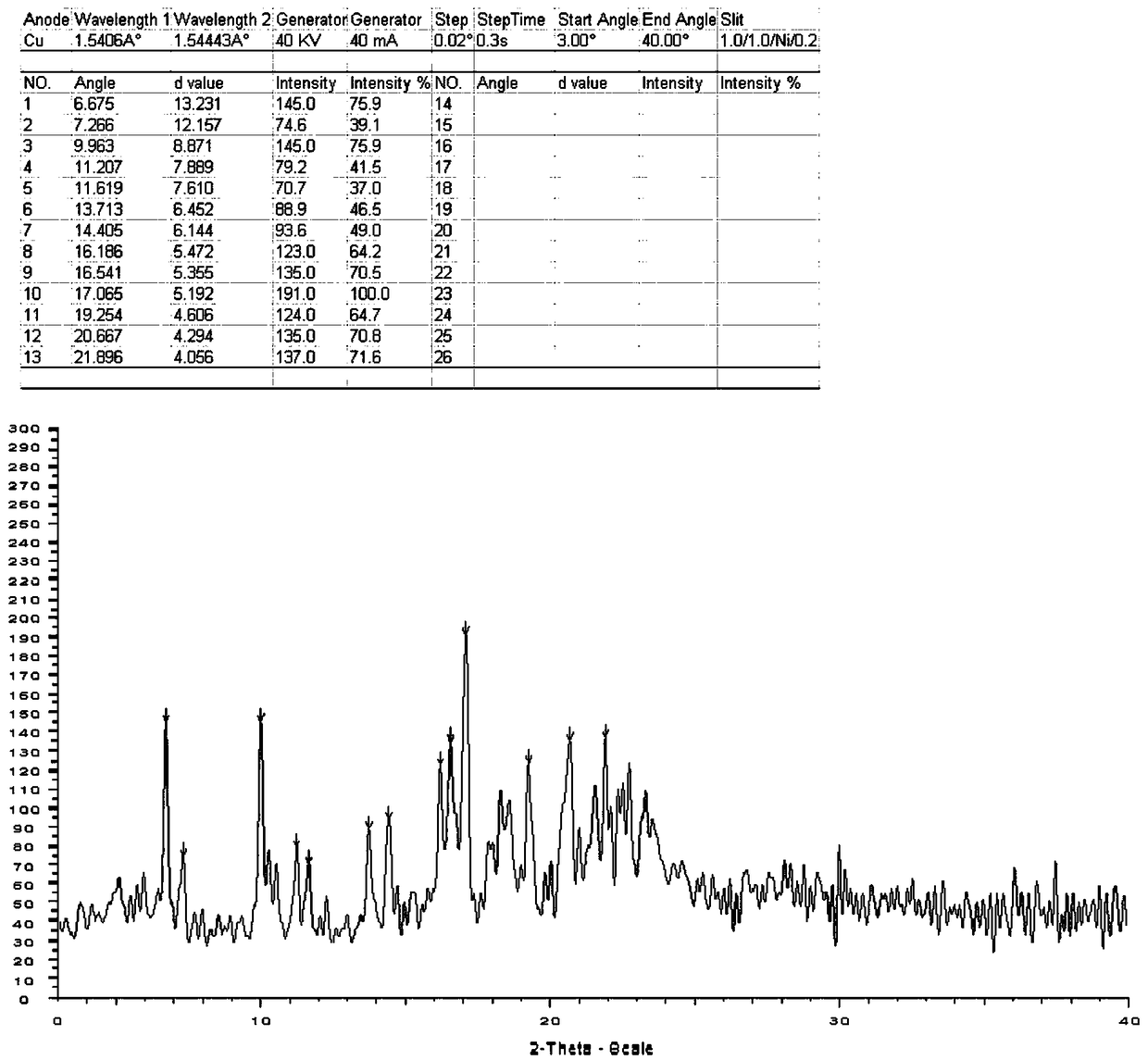

[0041] Take 10 g of sugammadex sodium, add it to a three-necked flask, add 50 mL of water into the flask, and stir to dissolve. The temperature was raised to 75°C under stirring, the stirring speed was 200r / min, 300mL of 1,4-dioxane was added dropwise to the solution, and the stirring was cooled down to room temperature, a large amount of white solids were precipitated. After suction filtration, the filter cake was vacuum-dried to dryness to obtain 9.2 g of sugammadex sodium. See XRD diagram Figure 6 .

Embodiment 2

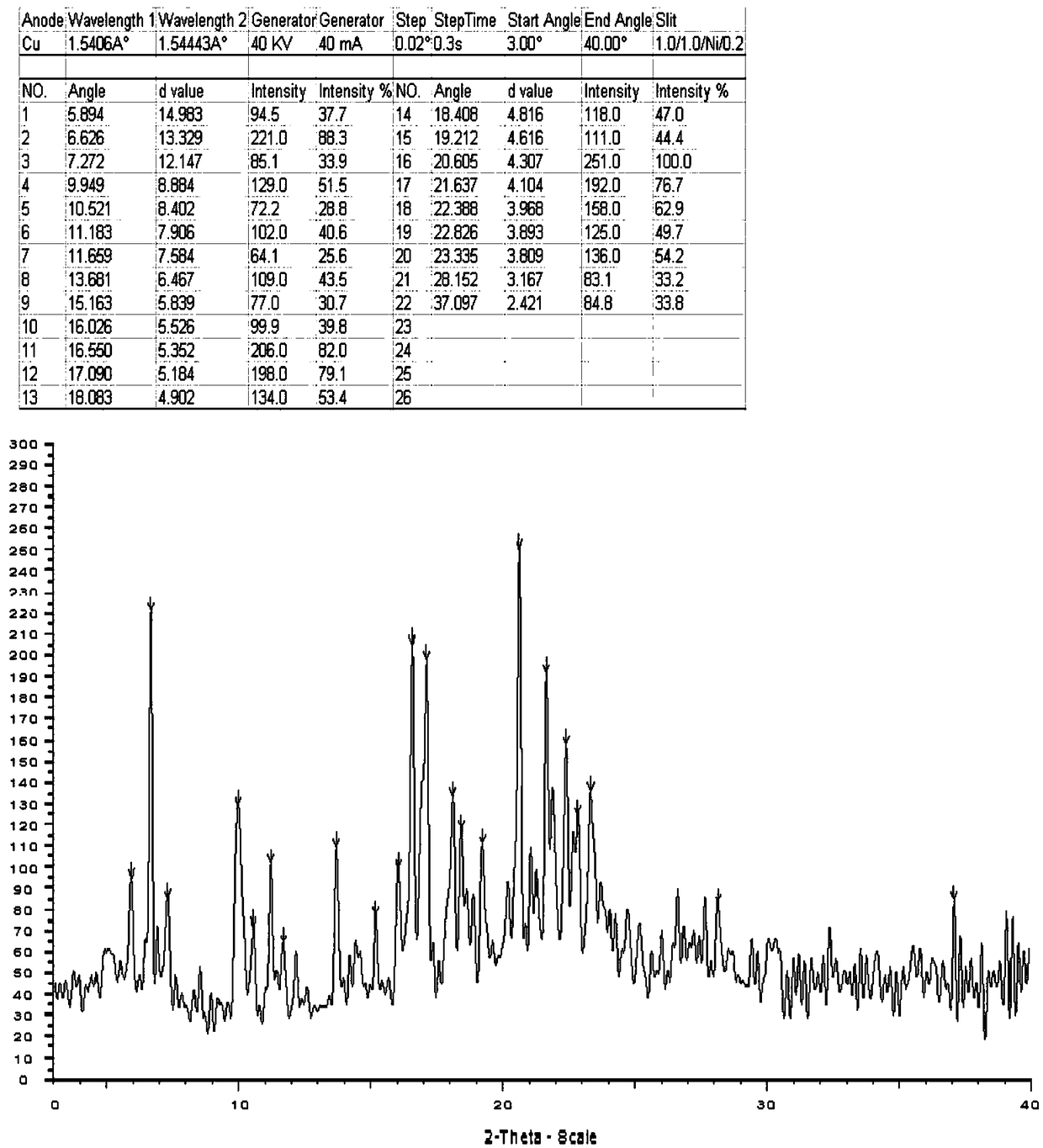

[0043] Take 10 g of sugammadex sodium, add it to a three-necked flask, add 200 mL of water into the flask, and stir to dissolve. Under nitrogen protection, the stirring speed was 100 r / min, and 1 L of tetrahydrofuran was added to the solution at room temperature. After the addition, a large amount of white solid precipitated out. Suction filtration, air-dried filter cake to dryness, 9.5g of pure Desugammadex Sodium, XRD figure see Figure 7 .

Embodiment 3

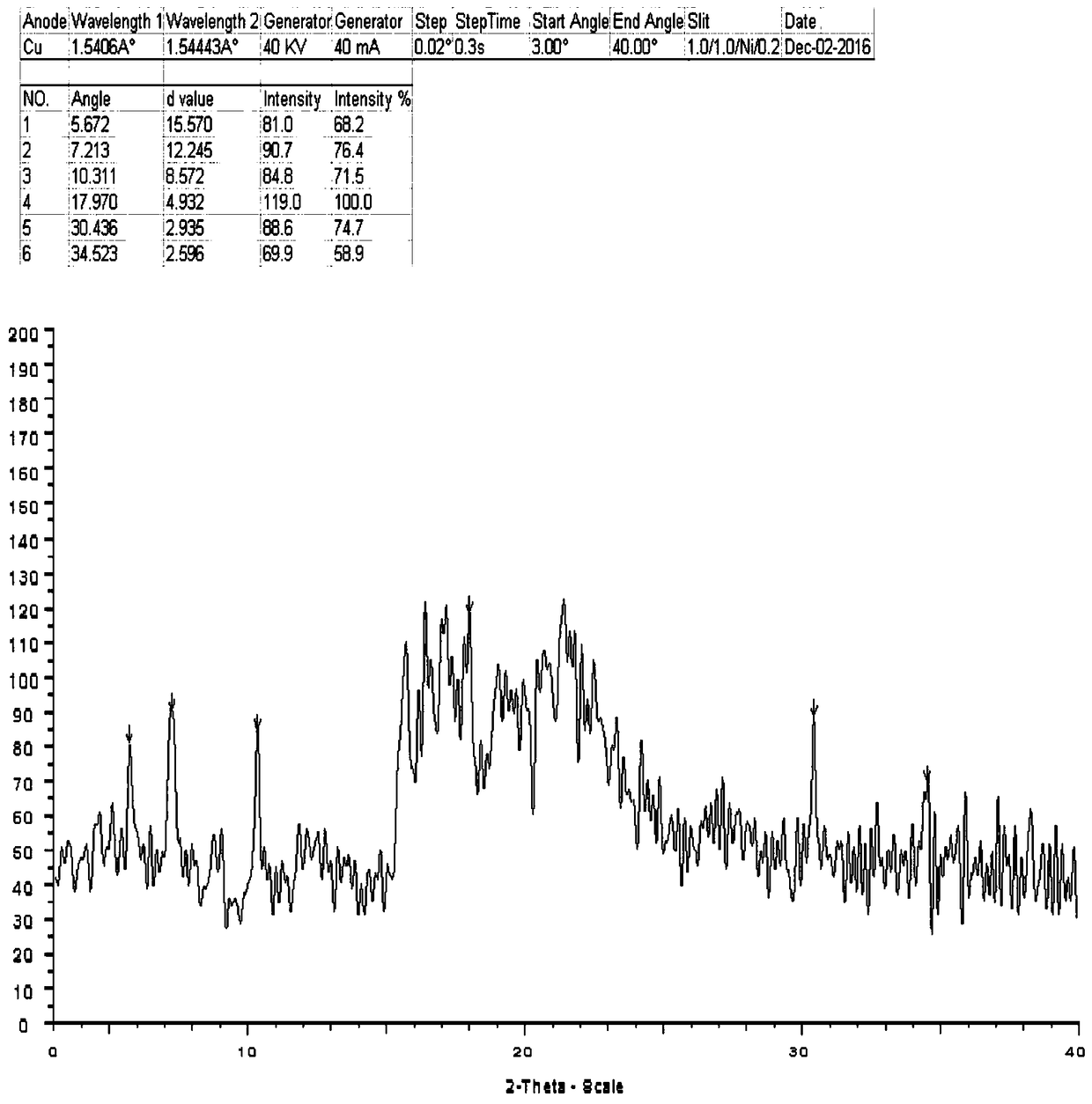

[0045] Take 10 g of sugammadex sodium crude product, add it into a three-necked flask, add 30 mL of water into the flask, and stir to dissolve. The solution is concentrated to dryness, and the pure product of Desugammadex Sodium is 10g, and the XRD pattern is shown in Figure 8 .

[0046]Different from Comparative Examples 1 to 5, the above-mentioned Examples 1 and 2 respectively select 1,4-dioxane and tetrahydrofuran as the crystallization solvent, and the sugammadex sodium prepared by direct drying in Example 3, the XRD pattern shows No obvious diffraction peaks were seen, indicating that the above products are all amorphous products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com