Comprehensive Recovery Method of 2-Mercaptobenzothiazole, Triethylamine and Dichloromethane in Ceftriaxone Sodium Dichloromethane Mother Liquor

A technology of mercaptobenzothiazole and ceftriaxone sodium, which is applied in the field of comprehensive recovery of 2-mercaptobenzothiazole, triethylamine and methylene chloride, can solve problems such as harm, M purity reduction, and environmental pollution, and achieve good Practical prospects, good performance, and the effect of reducing the amount of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

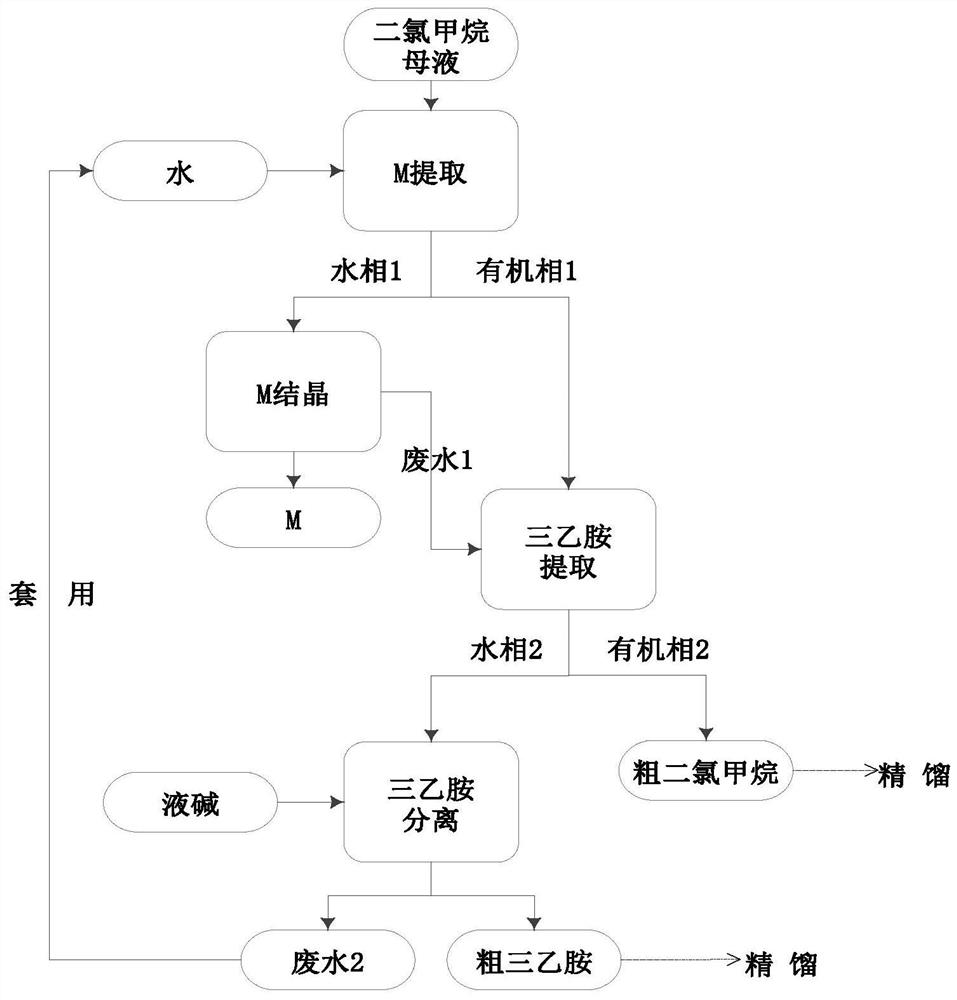

Image

Examples

Embodiment 1

[0034] (1) reclaim 2-mercaptobenzothiazole

[0035] Get ceftriaxone sodium dichloromethane mother liquor 3L (M content: 4wt%, triethylamine content: 3wt%, dichloromethane content: 91.5wt%, impurity 1.5wt%), add 3L water, with 30wt% sodium hydroxide The pH value of the solution is adjusted to 12, and the temperature is controlled at 10-15°C during the adjustment process, vigorously stirred for 1 hour, and left to separate phases to obtain an organic phase 1 and an aqueous phase 1; The value is adjusted to 6, the temperature is controlled at 15°C-20°C during this process, and a large amount of khaki solid is precipitated, then filtered, washed with water, and dried to obtain 146.1g of 2-mercaptobenzothiazole, with a content of 98.56% (as determined by liquid chromatography, quantitative analysis) , the recovery rate was 92.3%. At the same time, the filtered filtrate (ie waste water 1) was collected.

[0036] (2) reclaim triethylamine

[0037] Add 3L of the filtrate (i.e. wast...

Embodiment 2

[0042] (1) reclaim 2-mercaptobenzothiazole

[0043] Get ceftriaxone sodium dichloromethane mother liquor 3L (M content: 4wt%, triethylamine content: 3wt%, dichloromethane content: 91.5wt%, impurity 1.5wt%), add 3L embodiment 1 step (2) recovery Wastewater 2 produced by triethylamine, the pH value is adjusted to 13 with 30wt% sodium hydroxide solution, the temperature is controlled at 15-20°C during the adjustment process, vigorously stirred for 2 hours, and the phases are separated to obtain the organic phase 1 and the water phase 1. Adjust the pH value of the water phase 1 to 9 with 92.5wt% sulfuric acid. During this process, the temperature is controlled at 5°C-10°C, and a large amount of khaki solid is precipitated, then filtered, washed with water, and dried to obtain 143.7g of 2-mercaptobenzothiazole , content 98.21% (as determined by liquid chromatography, quantitative analysis), recovery 90.5%. Collect the filtered filtrate (i.e., waste water 1) at the same time.

[0...

Embodiment 3

[0050] (1) reclaim 2-mercaptobenzothiazole

[0051] Get ceftriaxone sodium dichloromethane mother liquor 3L (M content: 4wt%, triethylamine content: 3wt%, dichloromethane content: 91.5wt%, impurity 1.5wt%), add step (2) in 3L embodiment 2 Recover the waste water 2 produced by triethylamine, adjust the pH value to 13 with 30wt% sodium hydroxide solution, control the temperature at 15-20°C during the adjustment process, stir vigorously for 1 hour, and stand to separate the phases to obtain the organic phase 1 and water Phase 1; the pH value of the aqueous phase 1 was adjusted to 7 with 50wt% sulfuric acid, and the temperature was controlled at 5°C-10°C during this process, and a large amount of khaki solid was precipitated, then filtered, washed with water, and dried to obtain 144.8g of 2-mercaptobenzothiazole , content 98.28% (determination by liquid chromatography, quantitative analysis), recovery rate 91.2%. At the same time, the filtered filtrate was collected.

[0052] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com