Sewage treatment process with aerating above liquid surface

A sewage treatment and liquid level technology, applied in water/sludge/sewage treatment, water aeration, aerobic process treatment, etc., can solve problems such as large air intake demand, large power consumption, and factory loss, and achieve reduction Electricity expenses, reducing operating costs, and the effect of reducing electricity expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

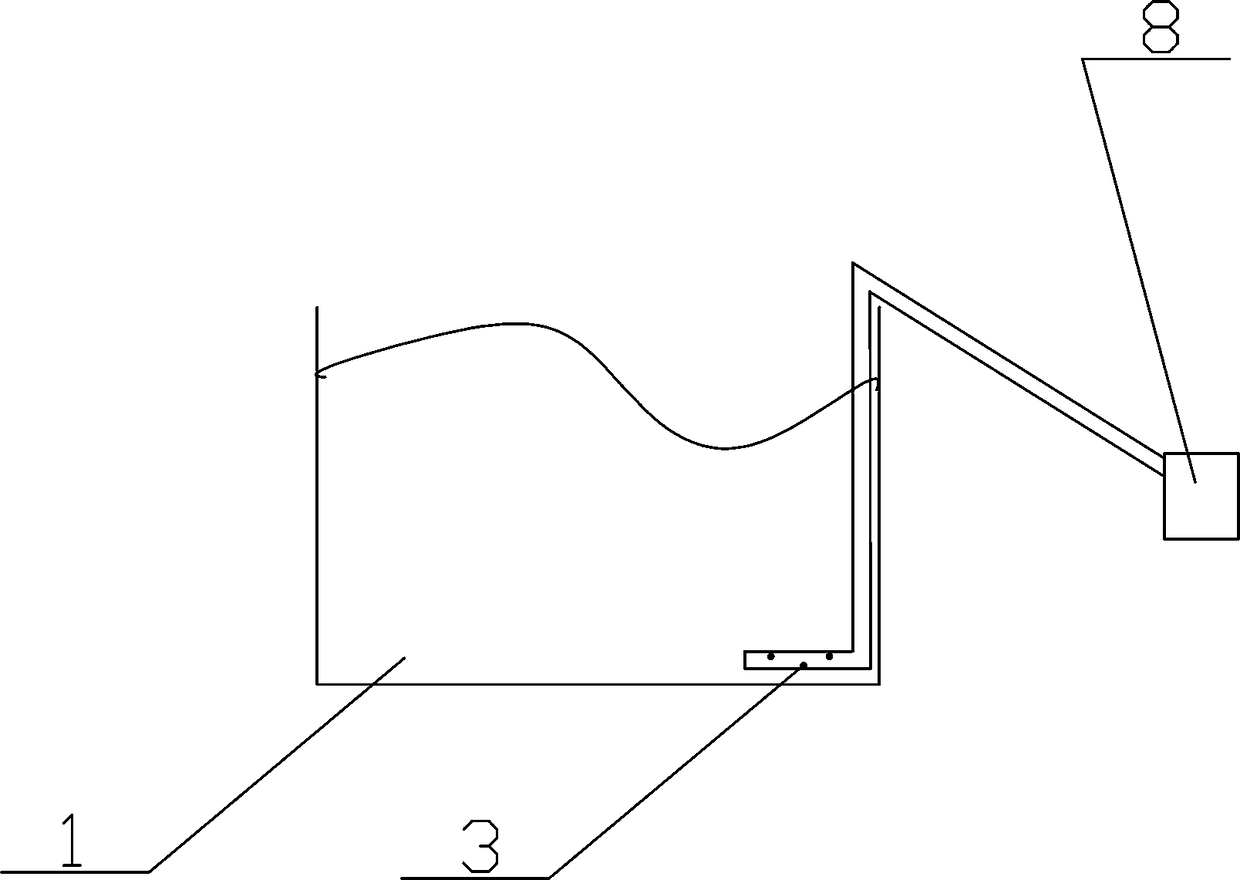

[0028] Such as Figure 5 As shown, the sewage treatment station has an aerobic sewage pool 1 with a total water volume of 600 cubic meters, sludge return flow of 30 cubic meters / h, and sewage incoming water of 30 cubic meters / h. The sewage contains high phosphate content (easy to cause pipe blockage). The existing aeration device is equipped with a 30-kilowatt blower fan 8 and adopts the bottom aeration method. It is understood that the current fan runs at full capacity throughout the day, and the water output index can only meet the discharge standard, which leads to huge energy consumption and increased expenses. That is to say, the amount of sewage per day is 30 cubic meters * 24 hours = 720 cubic meters. The electricity used in one day is 30 kilowatts * 24 hours = 720 kilowatts.

[0029] The bottom exposure method is that the fan 8 outside the sewage pool 1 passes the gas into the bottom of the sewage pool 1 through a pipeline, and sprays it out through the jet nozzle 3 ...

Embodiment 2

[0041] A sewage treatment process with aeration above the liquid level. The sewage oxygenation process includes: raising the sewage to 1.5 meters above the water surface, and then cooperating with the liquid level aerator 2 to fully integrate the sewage and air, and then hitting the bottom of the water through the jet nozzle 3 Squirt out.

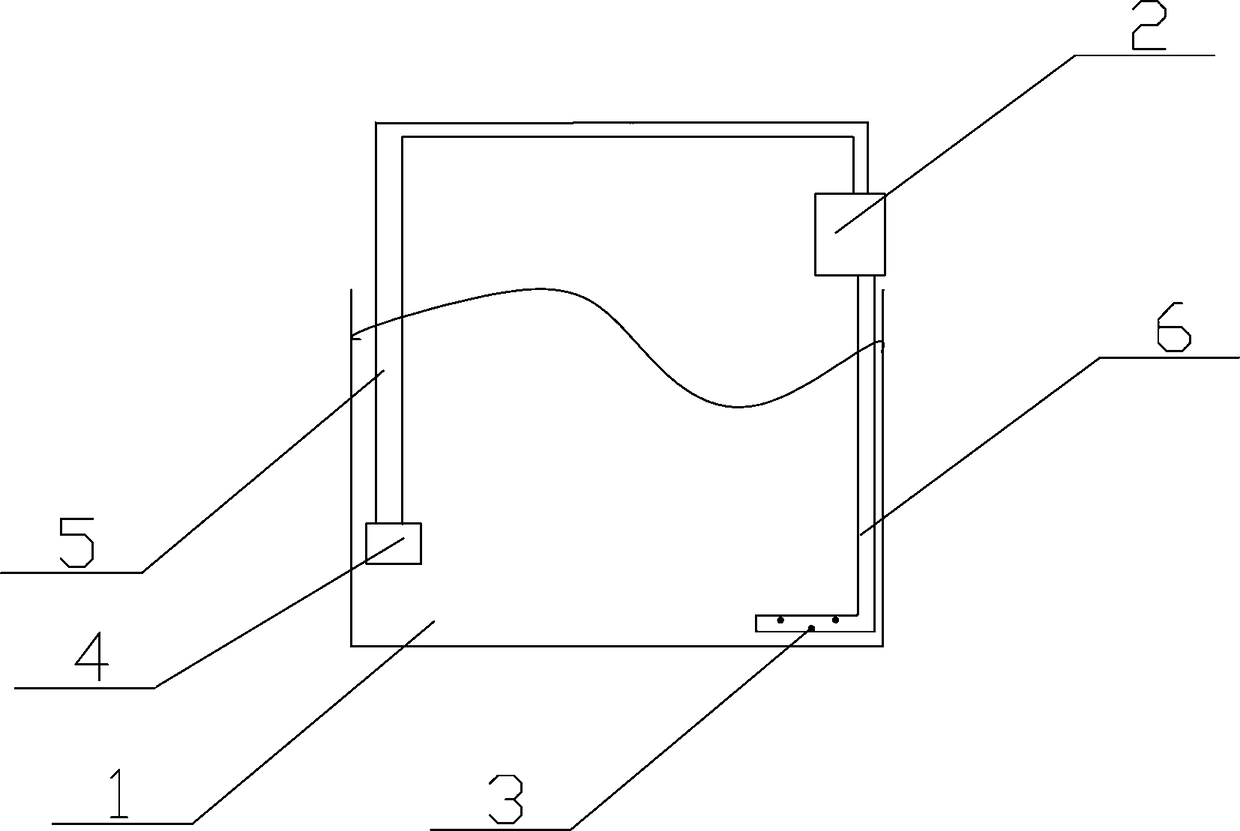

[0042] Such as figure 2 and Figure 4 As shown, the device for the sewage oxygenation process includes a sewage pool 1, a water pump 4 is arranged in the sewage pool 1, the water pump 4 is located below the sewage liquid level, and an aerator 2 is arranged at 1.5 meters above the sewage liquid level , the top of the aerator 2 is connected to the water pump 4 through the suction pipe 5, the bottom of the aerator 4 is connected to the water delivery pipe 6, and the other end of the water delivery pipe 6 is provided with a jet nozzle 3, and the jet nozzle 3 is located in the sewage below the liquid level.

[0043] The aerator 2 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com