Efficient thermal transfer printer

A thermal transfer printer, high-efficiency technology, applied in transfer printing, rotary printing presses, printing presses, etc., can solve the problems of no clothing leveling function, low efficiency, and only one operating platform for thermal transfer equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

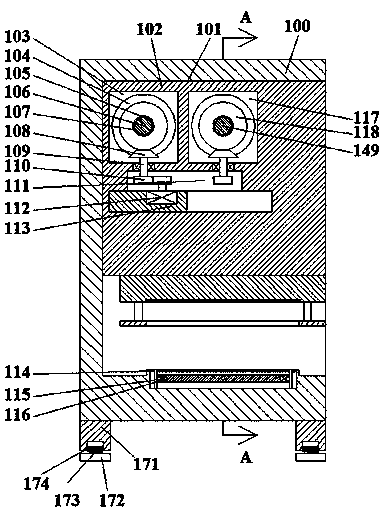

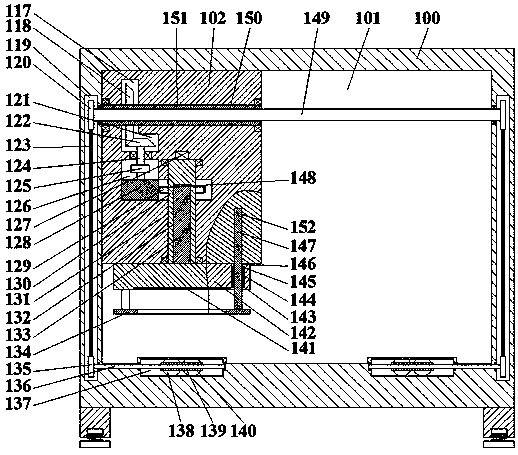

[0016] Such as Figure 1-Figure 2As shown, the high-efficiency thermal transfer printer of the present invention includes a body 100, a first sliding cavity 101 arranged in the body 100, and a first cavity 119 symmetrically arranged in the front and rear end walls of the body 100, A first sliding block 102 is provided to slide back and forth in the first sliding cavity 101, and a second cavity 117 and a third cavity on the left side of the second cavity 117 are arranged in the first sliding block 102. Cavity 103, the second cavity 117 is rotatably provided with spline sleeves 151 whose front and rear ends pass through the front and rear end walls of the first sliding block 102, and the spline sleeves 151 in the second cavity 117 The first bevel gear 118 is fixedly mounted on the outer surface, and the spline sleeve 151 is provided with a spline cavity 150 through the front and back, and the spline shaft 150 extending forward and backward is connected with the spline in the spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com