Lifting loading device and material distributing system with same

A technology of equipment and fabric, which is applied in the field of feeding equipment, can solve problems such as deviating from guide rails, running parts deviation, affecting material lifting efficiency and safety, etc., to achieve simple equipment installation, easy installation and maintenance, and reduce equipment failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

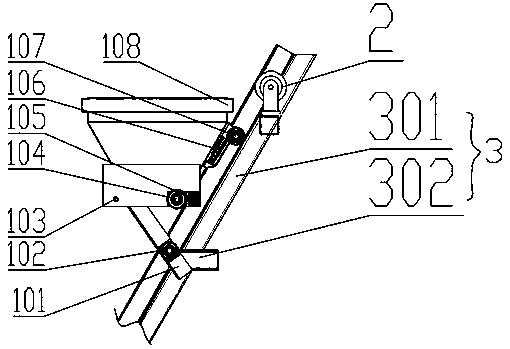

[0040] refer to figure 1 and figure 2 : A kind of lifting feeding equipment of the present embodiment, comprising a lifting bucket 1 and two inclined guide rails 301 for lifting the lifting bucket 1, the lifting bucket 1 includes a hopper body 108 and a discharge door located at the bottom of the hopper body 108 101, the end of the discharge door 101 away from the inclined guide track 301 is rotatably connected to the hopper body 108, and the end close to the inclined guide track 301 is provided with a first walking part 102 supported on the inclined guide track 301, and unloading Material door 101 is positioned between two inclined guide rails 301; Two inclined guide rails 301 are all provided with and communicate with it so that the first walking part 102 enters fork channel 302, and the side of hopper body 108 near inclined guide rail 301 is provided with a The second walking part 107 supported on the inclined guide track 301 is set, and the bottom of the hopper body 108 ...

Embodiment 2

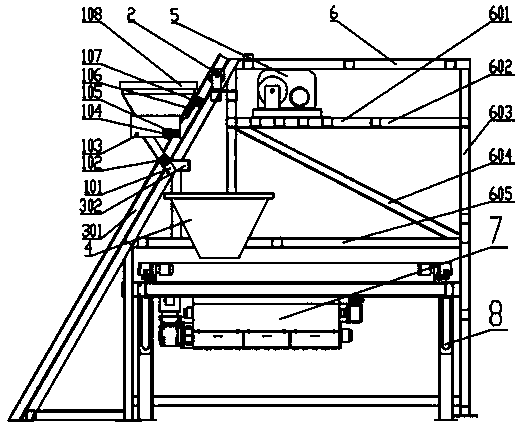

[0054] refer to Figure 3~6 , a distribution system, comprising a distribution rack 8, a distribution device 7, a bracket body 6 and the lifting and feeding device described in Embodiment 1; the inclined guide rail 301 of the lifting and feeding device is obliquely arranged on one side of the bracket body 6 , the driving device 5 is installed on the bracket main body 6;

[0055] Described bracket main body 6 is made up of pillar 603, crossbeam 602, lower platform 605 and upper platform 601, and described crossbeam 602 is installed on the pillar 603, and lower platform 605 and upper platform 601 are erected on crossbeam 602, and described lower platform 605 below A space is reserved for the installation of the cloth rack 8 , and the lower platform 605 of the support body 6 is provided with a receiving hopper 4 , which is located below the side of the fork channel 302 .

[0056] The hopper 4 is a quadrangular pyramid structure with a feed inlet on the top and a discharge outlet...

Embodiment 3

[0058] Compared with Embodiment 2, the cloth system of this embodiment has the following differences:

[0059] refer to Figure 7 , a corridor is provided on the lower platform 605, and ladders 607 connected to the ground and the upper platform 601 are provided on both sides of the corridor. The upper end of the ladder 607 is provided with a protective cage 606 . The ladder 607 is a straight ladder. In order to make it easier for maintenance personnel to go up and down, the ladder 607 can also be designed as an inclined ladder.

[0060] The upper platform 601 and the lower platform 605 of the bracket main body 6 are processed by checkered steel plates or steel gratings, and the pillars 603 and beams 602 are processed by angle steel, H-shaped steel or balance steel.

[0061] Guardrails are provided on the upper platform 601 and the lower platform 605 side parts except the lifting bucket 1 running track side.

[0062] A diagonal brace 604 is provided between the beam 602 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com