Wire pipe cutting device with the dust collecting function

A technology of cutting equipment and line pipe, applied in the field of line pipe cutting equipment, can solve problems such as reducing product quality, line pipe deviation, affecting line pipe quality, etc., to improve quality and accuracy, avoid extrusion deformation, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

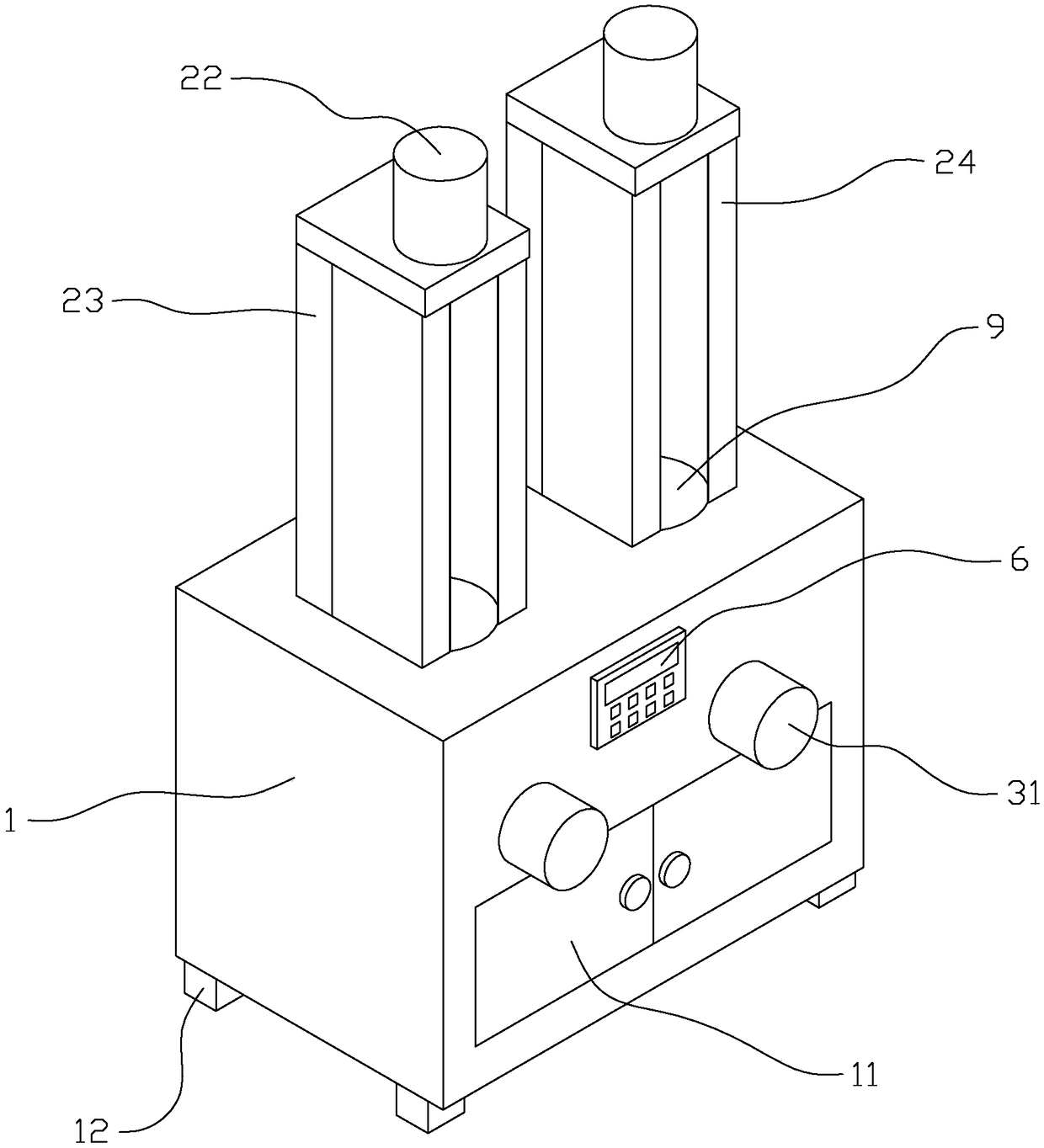

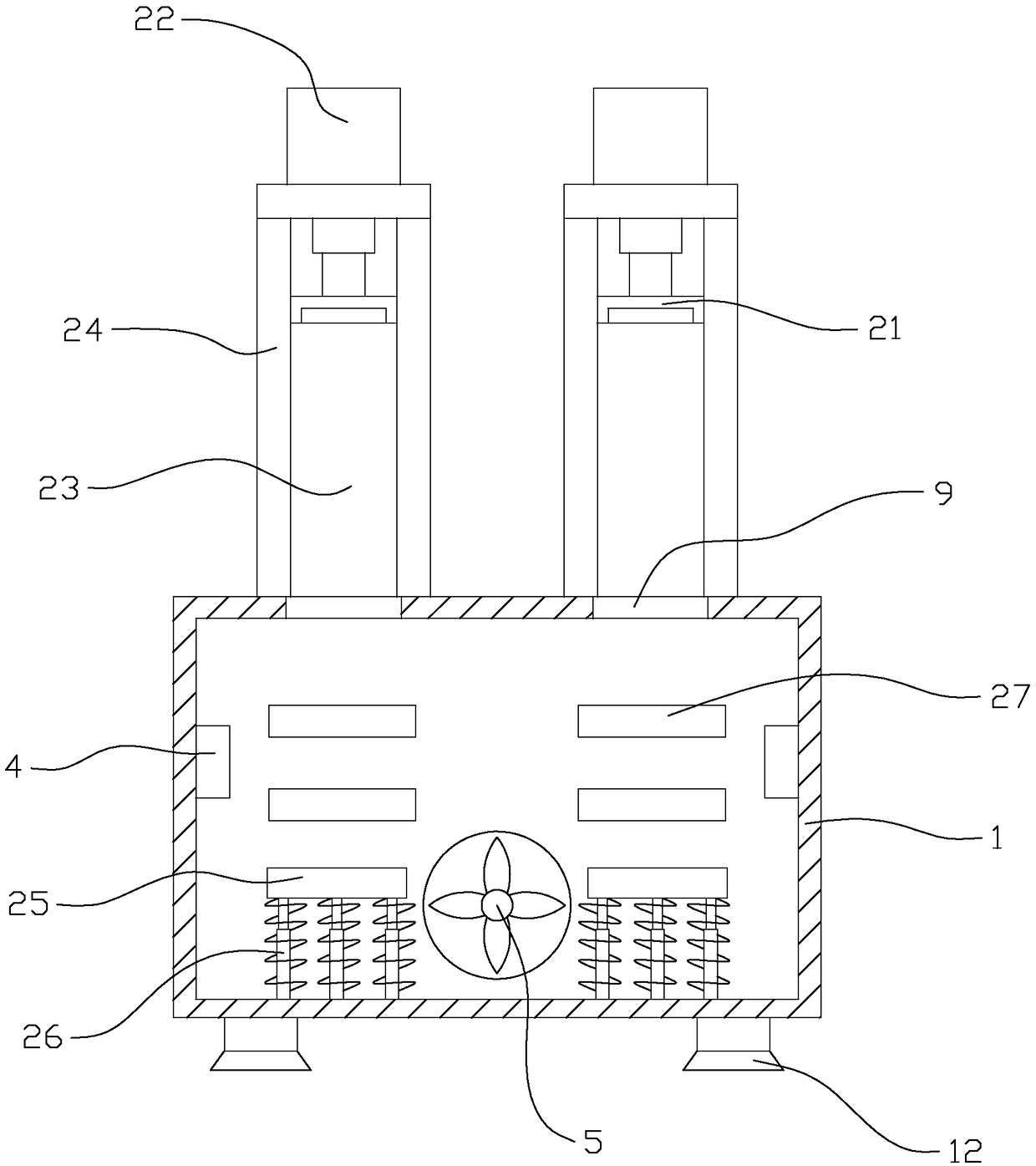

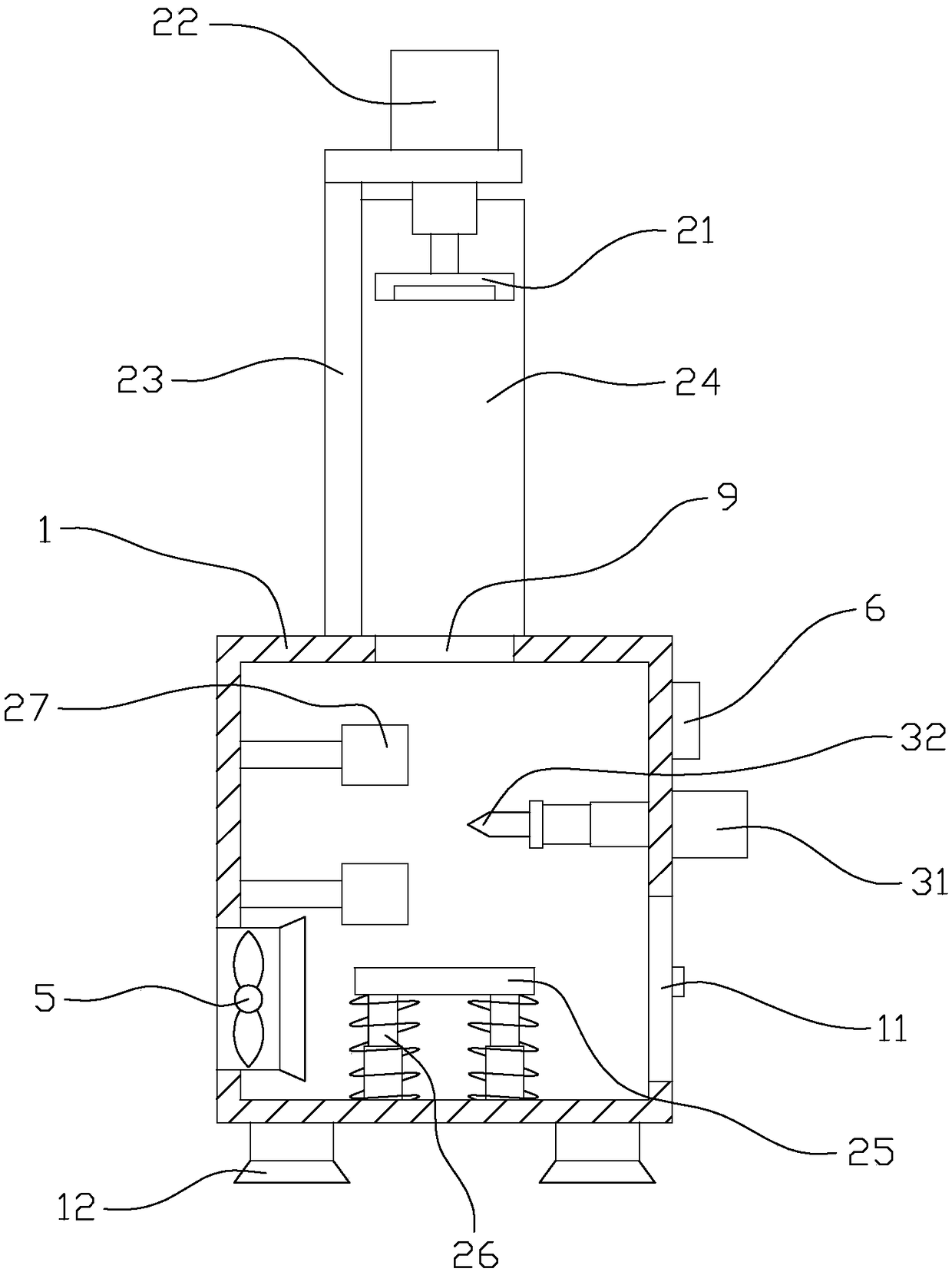

[0020] refer to Figure 1 to Figure 3 , a wire pipe cutting device with dust suction function, comprising a body shell 1, a wire pipe positioning device and a cutting device are arranged on the body shell 1, an opening 9 is provided on the top of the body shell 1 for the wire pipe to enter, The wire tube positioning device includes a pressing plate 21 arranged directly above the opening 9 and a bottom plate 25 arranged directly below the opening 9, the pressing plate 21 is connected with a driving cylinder 22, and the driving cylinder 22 is fixed by a bracket 23 On the body shell 1, the bracket 23 is provided with two splints 24 positioned on both sides of the opening 9. Preferably, the bracket 23 includes a vertical plate and a horizontal plate arranged on the top of the vertical plate, and the vertical plate is close to the vertical plate. The rear side edge of the opening 9, the driving cylinder 22 is fixedly installed on the horizontal plate, the inner surface of the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com