Pipeline clamping device for vertical welding table

A technology of clamping device and welding table, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large heat input, etc., and achieve the effect of stable welding quality, good effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

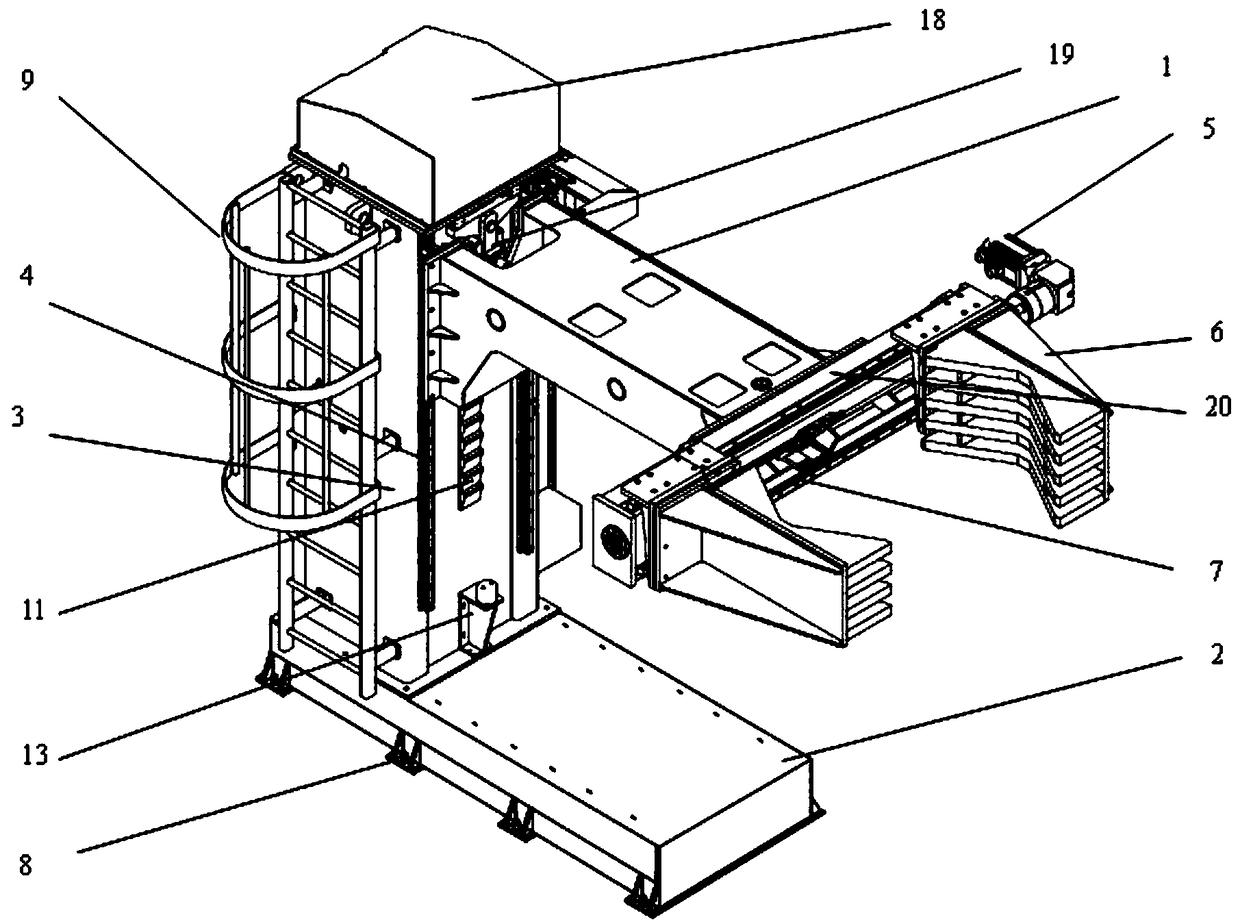

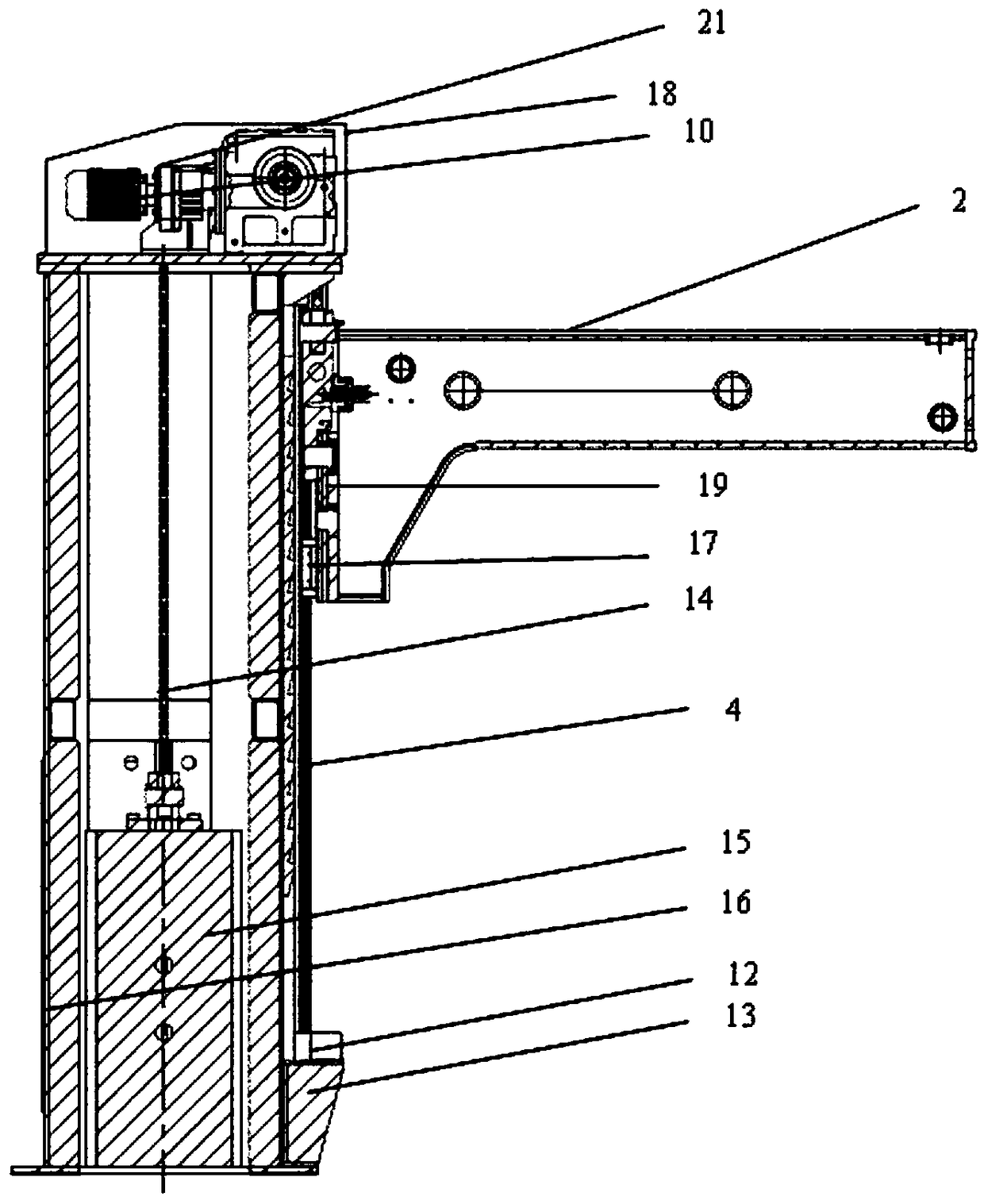

[0014] like figure 1 , figure 2 As shown, the pipeline clamping device of the vertical welding station of the present invention includes a cantilever 1, a base 2 and a column 3; A top cover 18 is provided on the top, and a first motor 10 is installed on the top of the column 3 inside the top cover 18. The first motor 10 controls the cantilever 1 to move up and down on the linear guide rail 4 through a chain, and the column 3 is installed on the outside of the linear guide rail wall. There is a locking rack 11, which cooperates with the locking device 19 installed on the cantilever to prevent the cantilever from sliding down when the cantilever is stationary; the bottom of the column 3 is provided with a linear guide rail 4 and the outside of the wall surface is provided with an up and down sliding limit device 12 to prevent the cantilever from slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com