Intelligent atomization method for feed warehouse environment

A warehouse and feed technology, applied in the field of intelligent atomization of feed warehouse environment, can solve the problems of feed mildew, unsuitable for feed warehouse use, no cooling, moisturizing and dust removal effects, etc., to prevent feed mildew, good moisturizing effect, The effect of increased space humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

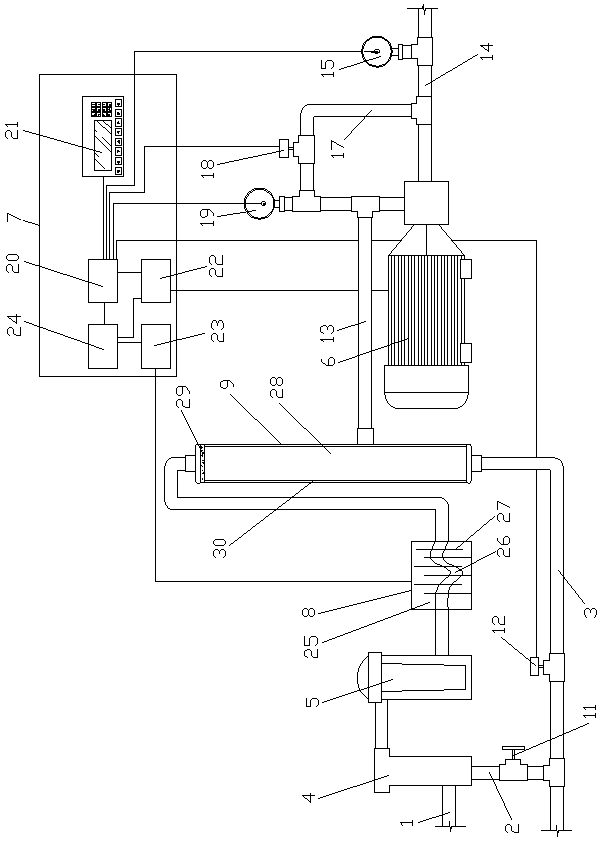

[0055] An intelligent atomization method for feed warehouse environment, comprising the following steps:

[0056] a, a plurality of temperature and humidity probes 10 are arranged in the feed warehouse space, and the temperature and humidity probes 10 transmit the monitored temperature data and relative humidity data to the PLC control box 7, and the PLC control box 7 judges whether the temperature data and the relative humidity data reach the preset set value;

[0057] b. When the temperature data and relative humidity data reach the preset value of the PLC control box 7, the PLC control box 7 controls the water to pass through the first-level pre-filter 4, the second-level pre-filter 5, and the electrolysis of the environmental intelligent atomization equipment in turn. Tank 8 and ultrafilter 9, the water after the four-stage purification treatment is pumped into the high-pressure outlet pipe 14 after being pressurized by the high-pressure plunger pump 6;

[0058] c. The wa...

Embodiment 2

[0061] An intelligent atomization method for feed warehouse environment, comprising the following steps:

[0062]a, a plurality of temperature and humidity probes 10 are arranged in the feed warehouse space, and the temperature and humidity probes 10 transmit the monitored temperature data and relative humidity data to the PLC control box 7, and the PLC control box 7 judges whether the temperature data and the relative humidity data reach the preset set value;

[0063] b. When the temperature data and relative humidity data reach the preset value of the PLC control box 7, the PLC control box 7 controls the water to pass through the first-level pre-filter 4, the second-level pre-filter 5, and the electrolysis of the environmental intelligent atomization equipment in turn. Tank 8 and ultrafilter 9, the water after the four-stage purification treatment is pumped into the high-pressure outlet pipe 14 after being pressurized by the high-pressure plunger pump 6;

[0064] c. The wat...

Embodiment 3

[0071] An intelligent atomization method for feed warehouse environment, comprising the following steps:

[0072] a, a plurality of temperature and humidity probes 10 are arranged in the feed warehouse space, and the temperature and humidity probes 10 transmit the monitored temperature data and relative humidity data to the PLC control box 7, and the PLC control box 7 judges whether the temperature data and the relative humidity data reach the preset set value;

[0073] b. When the temperature data and relative humidity data reach the preset value of the PLC control box 7, the PLC control box 7 controls the water to pass through the first-level pre-filter 4, the second-level pre-filter 5, and the electrolysis of the environmental intelligent atomization equipment in turn. Tank 8 and ultrafilter 9, the water after the four-stage purification treatment is pumped into the high-pressure outlet pipe 14 after being pressurized by the high-pressure plunger pump 6;

[0074] c. The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com