Mustard prickling technology based on sectioned pressurizing

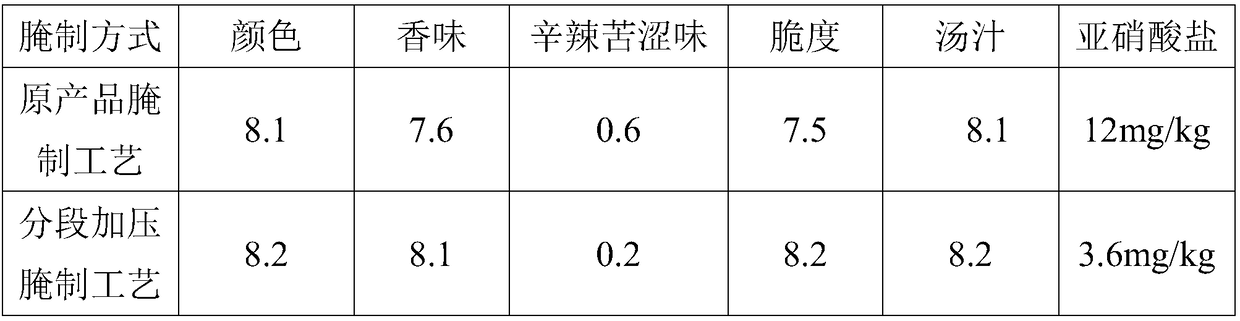

A technology of segmented pressurization and mustard greens, applied in food ingredients as taste improvers, food ingredients as taste improvers, climate change adaptation and other directions, can solve the problems of turbid product soup, product spoilage and external mechanical damage, etc. To achieve the effect of reducing the production of nitrite, avoiding mechanical damage and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] A process for pickling mustard in stages and pressurized, comprising the following steps;

[0033] 1) Choose mustard greens that are large, green in color, have few yellow leaves, fresh and tender without disease spots, and frostbitten, remove the soil, flatten the roots, and turn them in the sun for 2 days to remove 20% of the water;

[0034] 2) Clean the pickling pool with water, dry the water on the inner wall of the pickling pool, spread 1 ton of salt on the bottom of the pickling pool, spread evenly, choose 100 tons of dehydrated mustard greens as raw materials, and then start to put the mustard greens, the mustard greens are arranged neatly, each Layer vegetables, sprinkle a layer of salt, and use 15 tons of salt in the middle. Each layer is compacted by manual stepping. When pickling the pond, spread 1 ton of salt on the top of the pickling pond; choose a square pond of 6m x 4m x 5m with epoxy resin coating on the inner wall of the pickling pond. After paving, ma...

specific Embodiment 2

[0038] A process for pickling mustard in stages and pressurized, comprising the following steps;

[0039] 1) Choose mustard greens that are large, green in color, have few yellow leaves, fresh and tender without disease spots, and frostbitten, remove the soil, flatten the roots, and turn them in the sun for 2 days to remove 15% of the water;

[0040] 2) Clean the pickling pool with water, dry the water on the inner wall of the pickling pool, spread 1 ton of salt on the bottom of the pickling pool, spread evenly, choose 100 tons of dehydrated mustard greens as raw materials, and then start to put shepherd's purse, the shepherd's purse is arranged neatly, each Layer vegetables, sprinkle a layer of salt, and use 14 tons of salt in the middle. Each layer is compacted by manual stepping. When pickling the pond, spread 1 ton of salt on the top of the pickling pond; choose a square pond of 6m x 4m x 5m with epoxy resin coating on the inner wall of the pickling pond. After paving, mak...

Embodiment 3

[0045] A process for pickling mustard in stages and pressurized, comprising the following steps;

[0046] 1) Choose mustard greens that are large, green in color, with few yellow leaves, fresh and free of disease spots, and frostbitten, remove the soil, flatten the roots, and turn them in the sun for 2 days to remove 18% of the water;

[0047] 2) Clean the pickling pool with water, dry the water on the inner wall of the pickling pool, spread 1 ton of salt on the bottom of the pickling pool, spread evenly, choose 100 tons of dehydrated mustard greens as raw materials, and then start to put the mustard greens, the mustard greens are arranged neatly, each Layer vegetables, sprinkle a layer of salt, and use 14.5 tons of salt in the middle. Each layer is compacted by manual stepping. When pickling the pond, spread 1 ton of salt on the top of the pickling pond; choose a square pond of 6m x 4m x 5m with epoxy resin coating on the inner wall of the pickling pond. After paving, make su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com