Non-sintered positive electrode and alkaline secondary battery having the same

A secondary battery, non-sintering technology, applied in the manufacture of secondary batteries, alkaline storage batteries, alkaline storage batteries, etc., can solve the problems of reducing active substances, alkaline electrolyte injection, difficulty in ensuring battery capacity, etc., and achieve long life , prolong battery life, inhibit swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

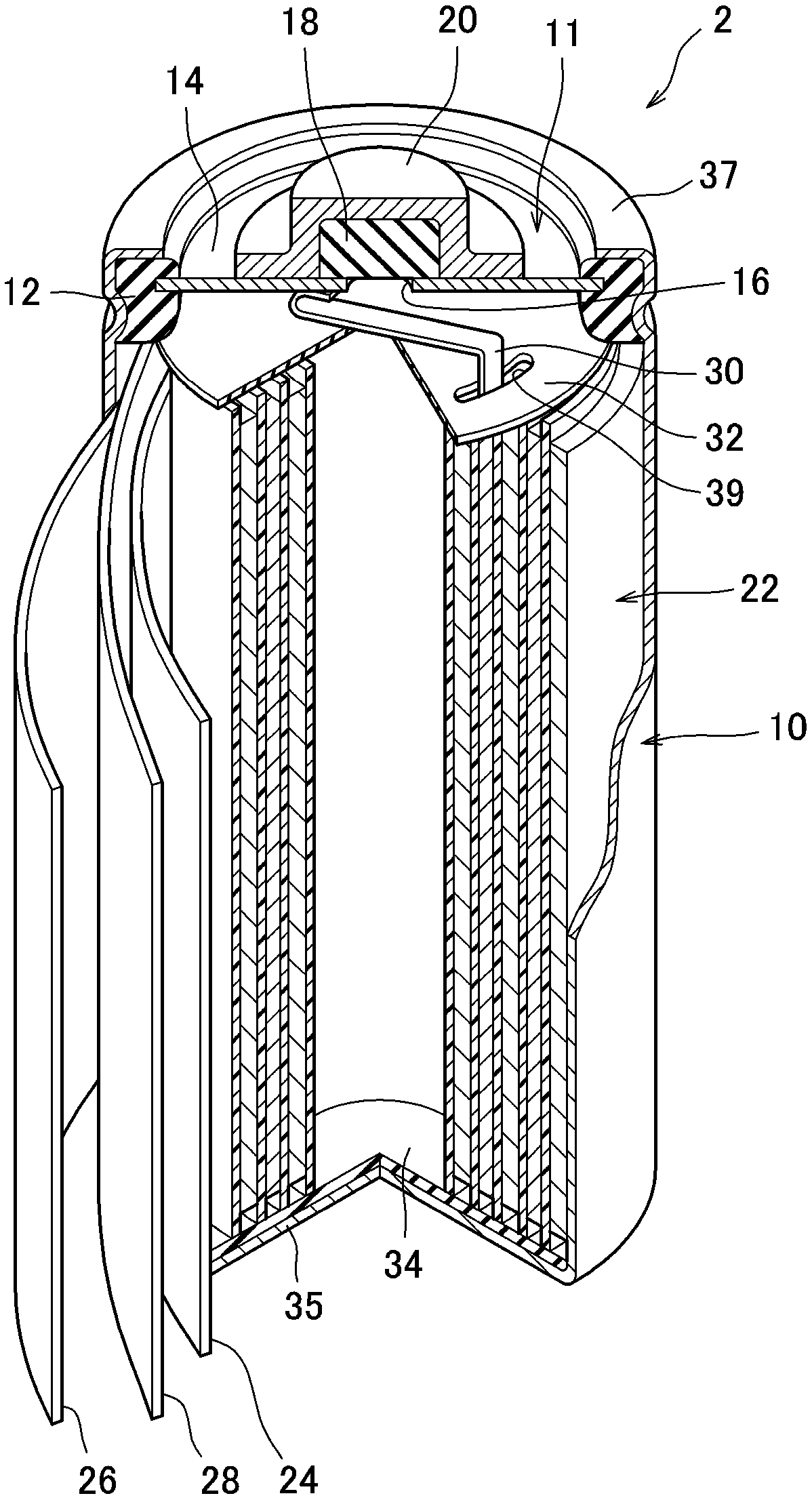

[0072] (1) Manufacturing of positive electrode

[0073] On the condition that zinc is 3% by mass and cobalt is 1% by mass with respect to nickel, nickel sulfate, zinc sulfate, and cobalt sulfate are weighed and added to a 1N sodium hydroxide aqueous solution containing ammonium ions to prepare a mixed aqueous solution. While stirring the resulting mixed aqueous solution, a 10N sodium hydroxide aqueous solution was slowly added to the mixed aqueous solution to react. During the reaction, the pH was stabilized at 13-14, and nickel hydroxide was formed as the main component. , Zinc and cobalt are dissolved in the base particles.

[0074] After washing the obtained base particles three times with 10 times the amount of pure water, they are dehydrated and dried. In addition, the obtained base particles had a spherical shape with an average particle diameter of 10 μm.

[0075] Then, the obtained base particles were put into an aqueous ammonia solution, and while maintaining the pH during...

Embodiment 2

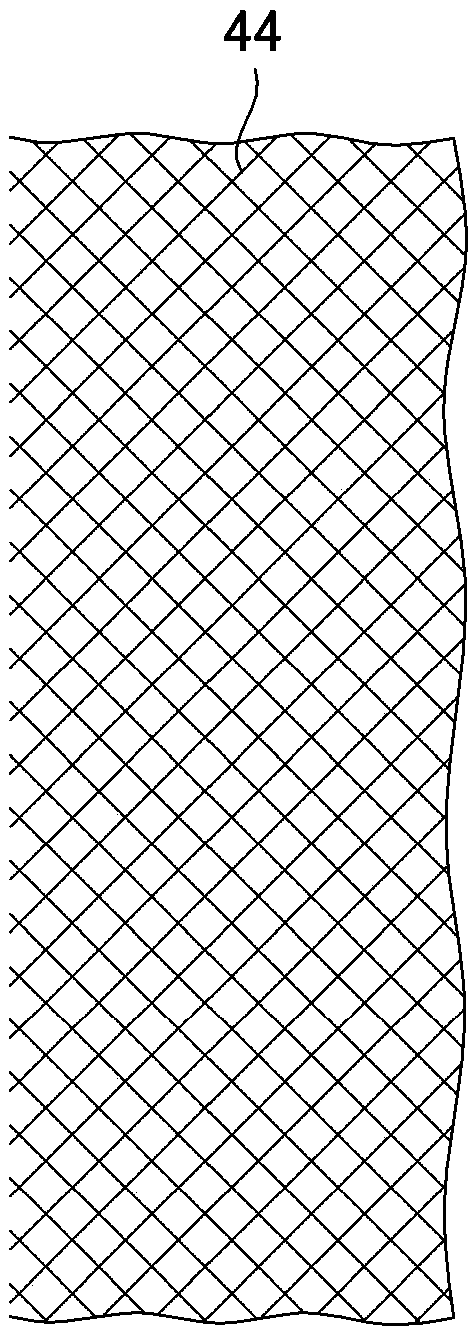

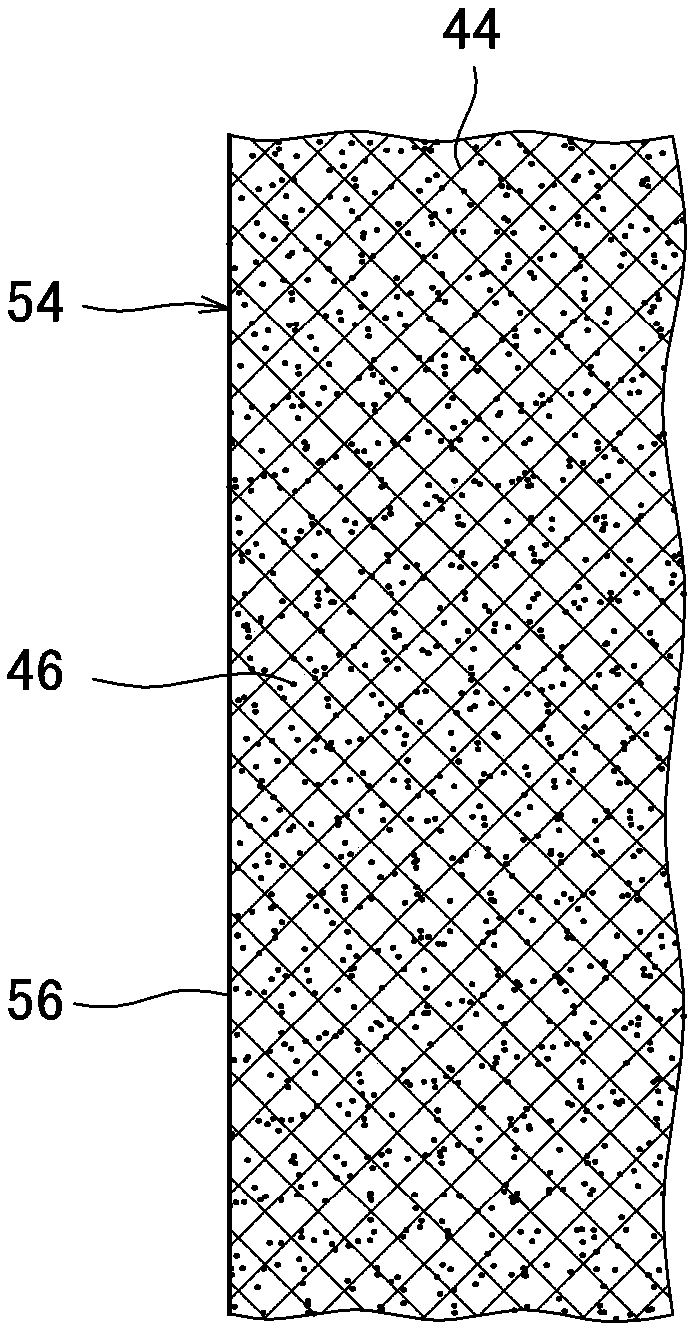

[0094] In addition to rolling with the nickel mesh metal loaded on the surface of the positive electrode intermediate product, it is manufactured by vacuum vapor deposition without nickel. There is a surface layer formed of nickel mesh metal on the surface of the positive electrode body 40. In the same manner as in Example 1, except for the positive electrode 24 of 42, a nickel-hydrogen secondary battery 2 in a usable state was produced.

[0095] The flat-mesh metal used in this example has a mesh shape formed by scribing slits on a nickel foil with a purity of 99.5% and then stretching it, and includes a skeleton part of the mesh and formed between the skeleton part The diamond-shaped through hole (opening). Here, as the sheet metal, a sheet metal having a foil thickness of 0.02 mm, an opening long side dimension of 1.0 mm, an opening short side dimension of 0.5 mm, and a frame portion width of 0.08 mm can be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com