Optimal scheduling method for hardware mould production process

A technology for optimizing scheduling and production processes, applied in computing models, artificial life, biological models, etc., to achieve the effects of improving production efficiency, shortening production cycles, and scheduling methods are reasonable and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

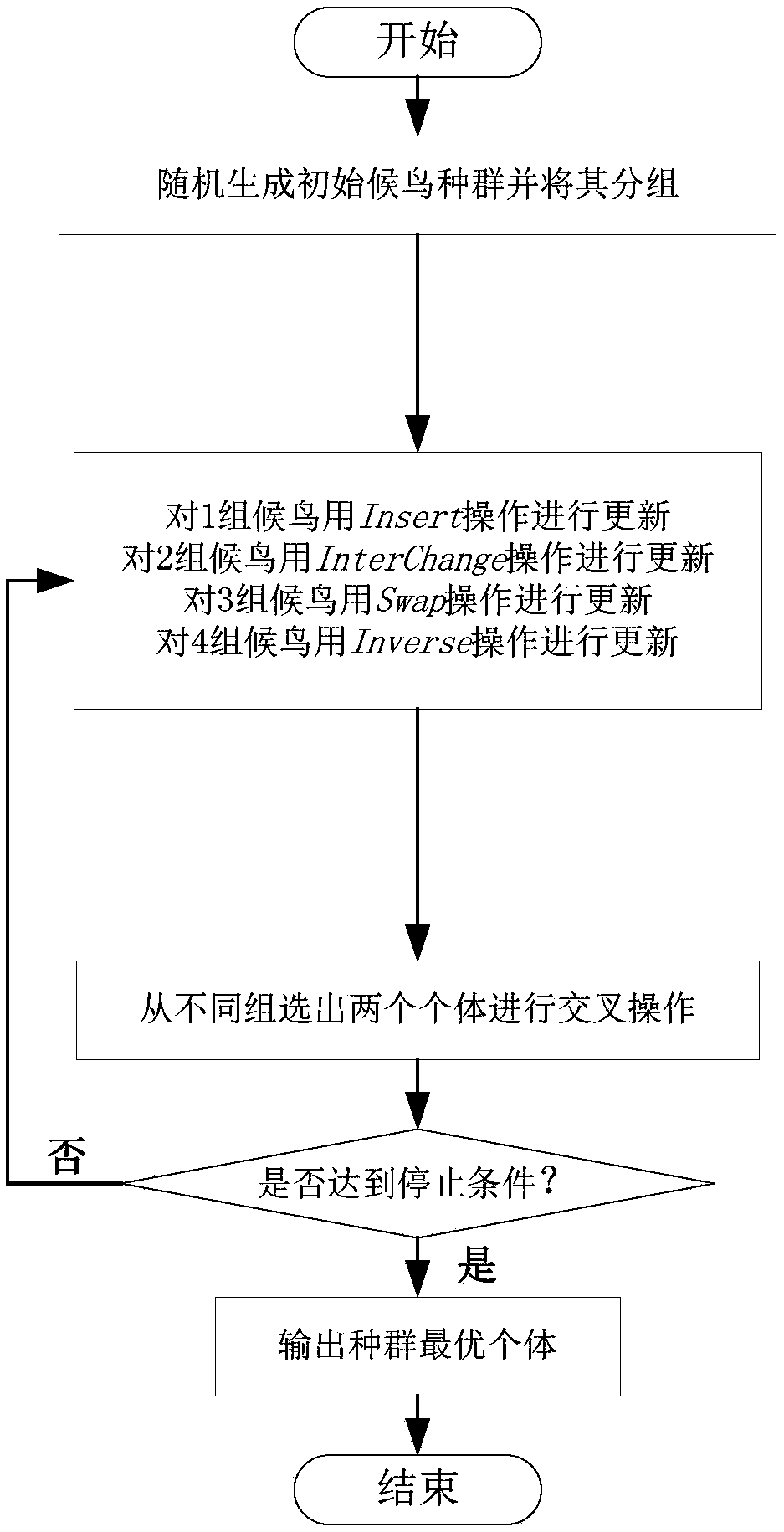

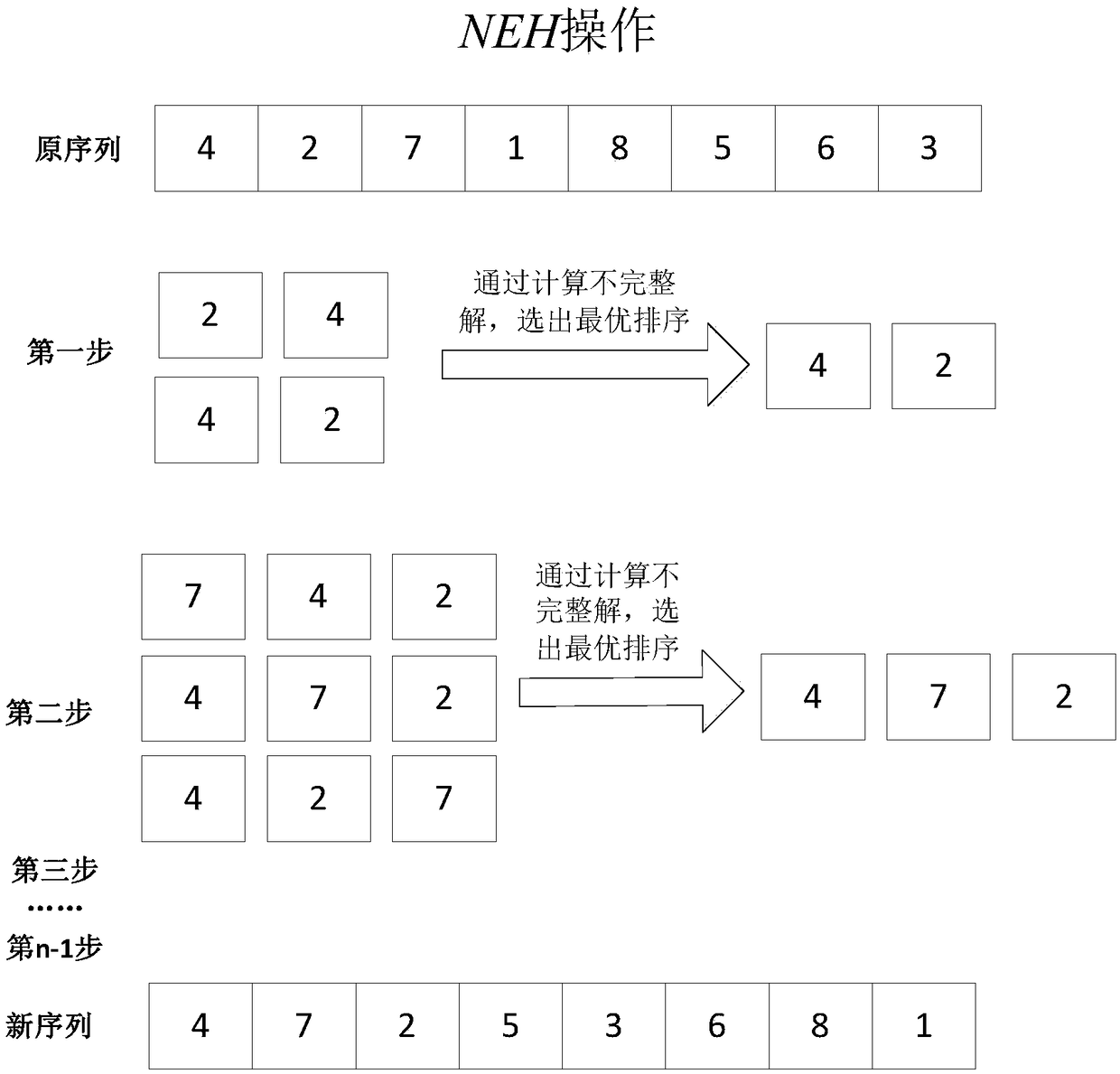

[0030] Embodiment 1: as Figure 1-8 As shown, an optimal scheduling method for the production process of metal molds, by determining the scheduling model and optimization objectives of the production process of hardware molds, and using the optimal scheduling method based on the mixed migratory bird algorithm to optimize the optimization objectives; the scheduling model is based on each mold The number of required operations and the processing time of the corresponding operations are established, and the optimization goal is to minimize the maximum completion time C max (π):

[0031]

[0032]

[0033]

[0034]

[0035]

[0036] In the formula, the number of metal molds is n, and the number of processing operations required is m; π={π 1 , π 2 ,…,π n} represents a solution to the optimal scheduling problem, π i is the i-th processed metal mold product in the processing sequence π; is the mold π i At the completion time after operation j finishes, Represen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com