A method of product process programming simulation for intelligent manufacturing of aeronautical machined products

A technology of intelligent manufacturing and process simulation, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as error-prone, complex processing characteristics of aircraft parts, and slow improvement of the overall level of aviation manufacturing, so as to reduce randomness sex and non-normative, pro-sharing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

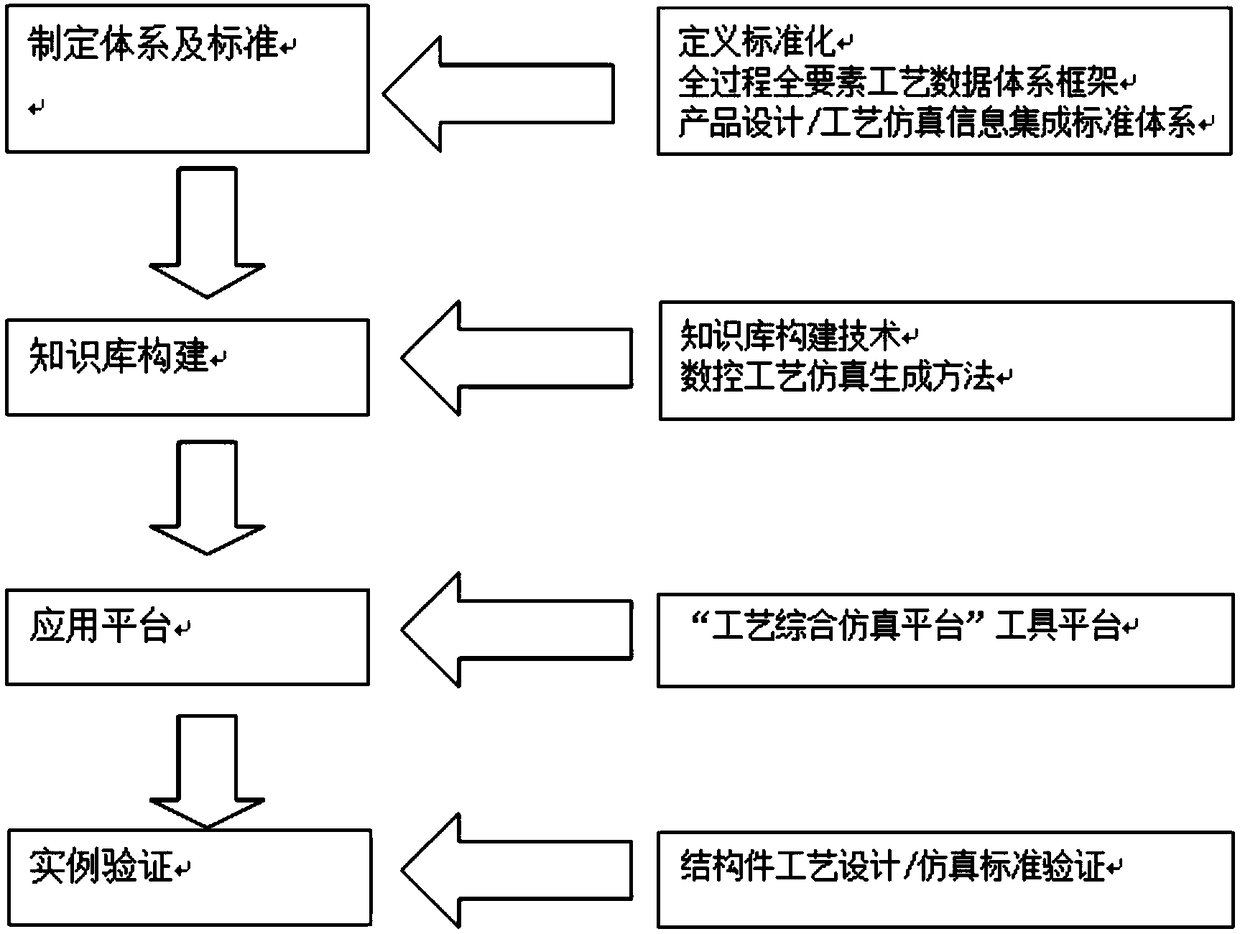

[0038] This method is like figure 1 As shown, the whole process of realizing intelligent manufacturing is fully described from four levels: standard setting, knowledge base construction, application platform construction and example verification. Specifically:

[0039] 1. Aircraft digital design / machine process simulation information integration standard system

[0040] 1.1 Standardization of Machine Design / Process Simulation Information Integration Definition

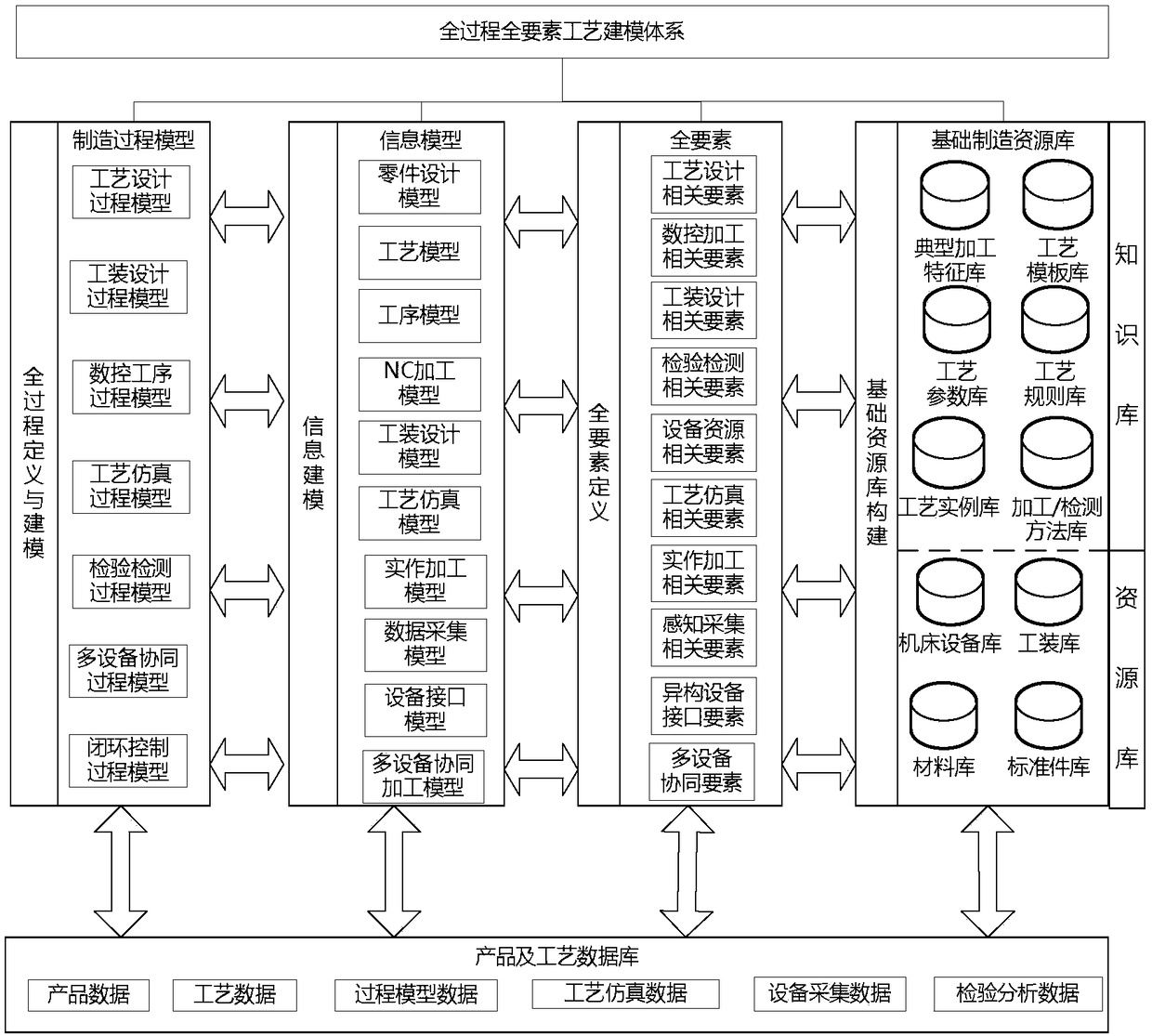

[0041] Facing the definition of the whole process, all-element machining process model and the preparation of related processing method specifications, study the complete definition of the construction method, process information, process information, and resource information involved in the design and process model construction, and systematically and systematically Standardized and standardized information processing and expression. On the basis of the definition of the whole-process and all-element art model system, anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com