An application method of big data in 3D printing technology

A technology of 3D printing and application method, applied in the direction of digital output to printing unit, input/output process of data processing, electrical digital data processing, etc., can solve the problem of limited accuracy of motor encoder, increase data processing difficulty, increase data transmission, etc problem, to achieve the effect of increasing the difficulty of data processing, reducing the amount of calculation, and simplifying data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

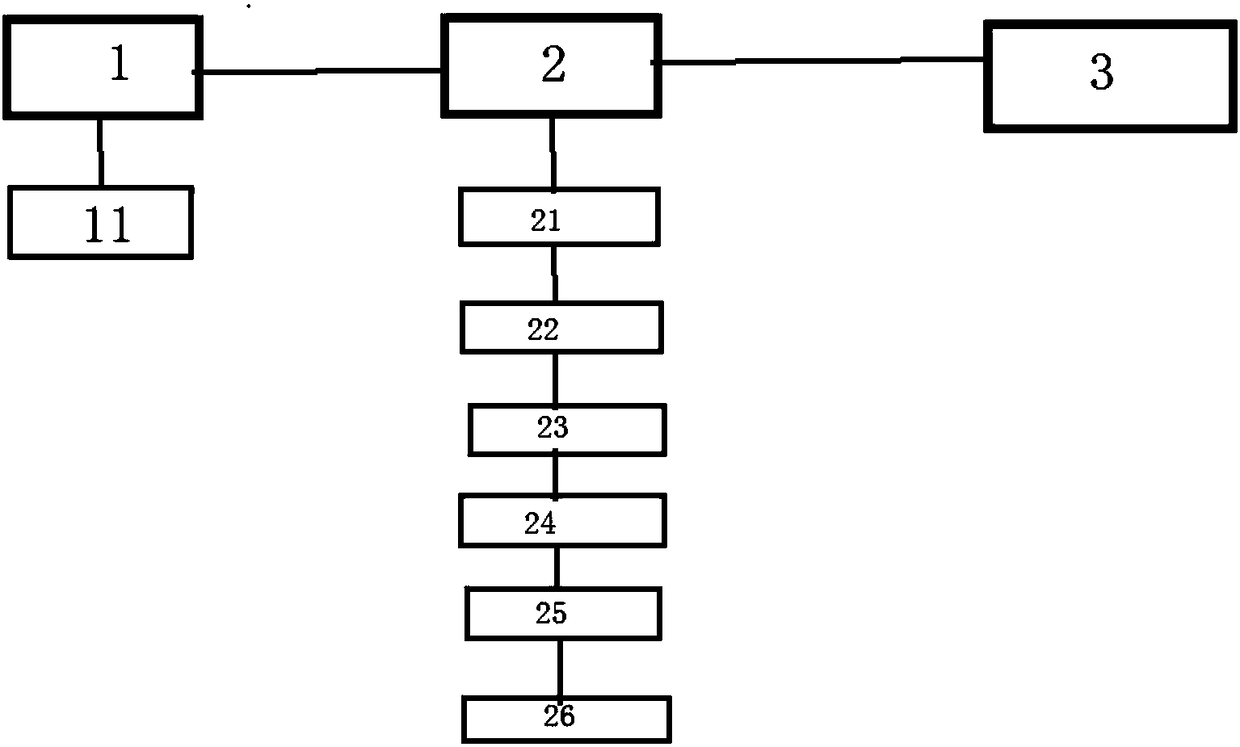

[0029] The present invention provides a method for applying big data in 3D printing technology. The method uses an online printing platform based on big data. The platform includes: a printing device, a server, and a client, and the client is connected to the server. The server is connected to the printing device, the client includes a computer or a mobile phone, and the server includes a network module, a data module, a storage module, an analysis module, an aggregation module and an application module connected in sequence;

[0030] Described method specifically comprises the steps:

[0031] 1) The printing equipment uses a high-energy heat source to heat the material according to the set parameters;

[0032] 2) The client sends the 3D printing requirements and 3D model to the server;

[0033] 3) The server connects the operating parameters to the cloud s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com