High-sensitivity flexible eddy current array sensor and monitoring method thereof

An array sensor and high-sensitivity technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as service environment interference, low sensor sensitivity, and vulnerability to environmental changes, and achieve enhanced engineering application value and high crack monitoring sensitivity , Inhibit the effect of ambient temperature and stress interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

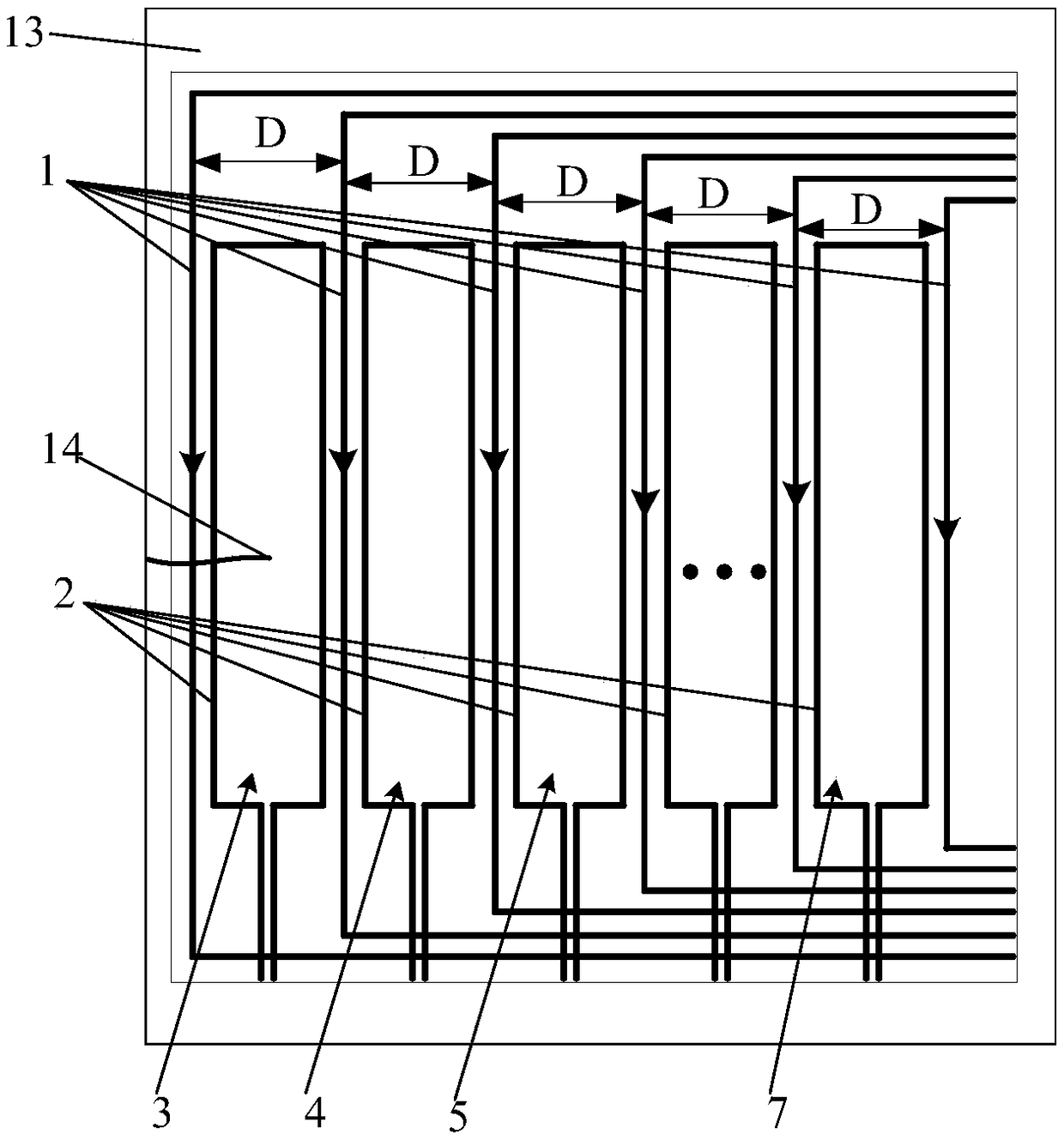

[0043] Such as Figure 1-5 As shown, a high-sensitivity flexible eddy current array sensor includes a sensor body and a connecting part 15, and the connecting part 15 is located on one side of the sensor body;

[0044] From top to bottom, the sensor body is the first protective film layer 8, the first coil layer 9, the flexible base layer 10, the second coil layer 11 and the second protective film layer 12;

[0045] The main body of the sensor also includes an excitation coil 1, and the excitation coil 1 includes two layout forms:

[0046] The excitation coil 1 is only arranged on the second coil layer 11 and forms a plurality of equally spaced rectangular units in the second coil layer 11, and the two ends of the excitation coil 1 are respectively connected to the connection part 15; or one end of the excitation coil 1 is connected to the connection part 15 are connected and arranged in the first coil layer 9 to form a plurality of equidistant rectangular units, and pass thr...

specific Embodiment 2

[0071] Roughly the same as specific embodiment 1, the difference only lies in:

[0072] In the first coil layer 9 and the second coil layer 11 , the distance between two adjacent rectangular units is equal, and the range of the distance D is 12 mm.

[0073] The range of the single frequency in step (2) is 10MHz.

specific Embodiment 3

[0074] Roughly the same as specific embodiment 1, the difference only lies in:

[0075] In the first coil layer 9 and the second coil layer 11 , the distance between two adjacent rectangular units is equal, and the range of the distance D is 6mm.

[0076] The range of the single frequency in step (2) is 5MHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com