Test device and test method for I-II composite crack fatigue propagation rate

A crack fatigue propagation, I-II technology, applied in the field of the I-II composite crack fatigue growth rate test device, can solve the problem of insufficient test accuracy and reliability, and inability to easily achieve sample alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

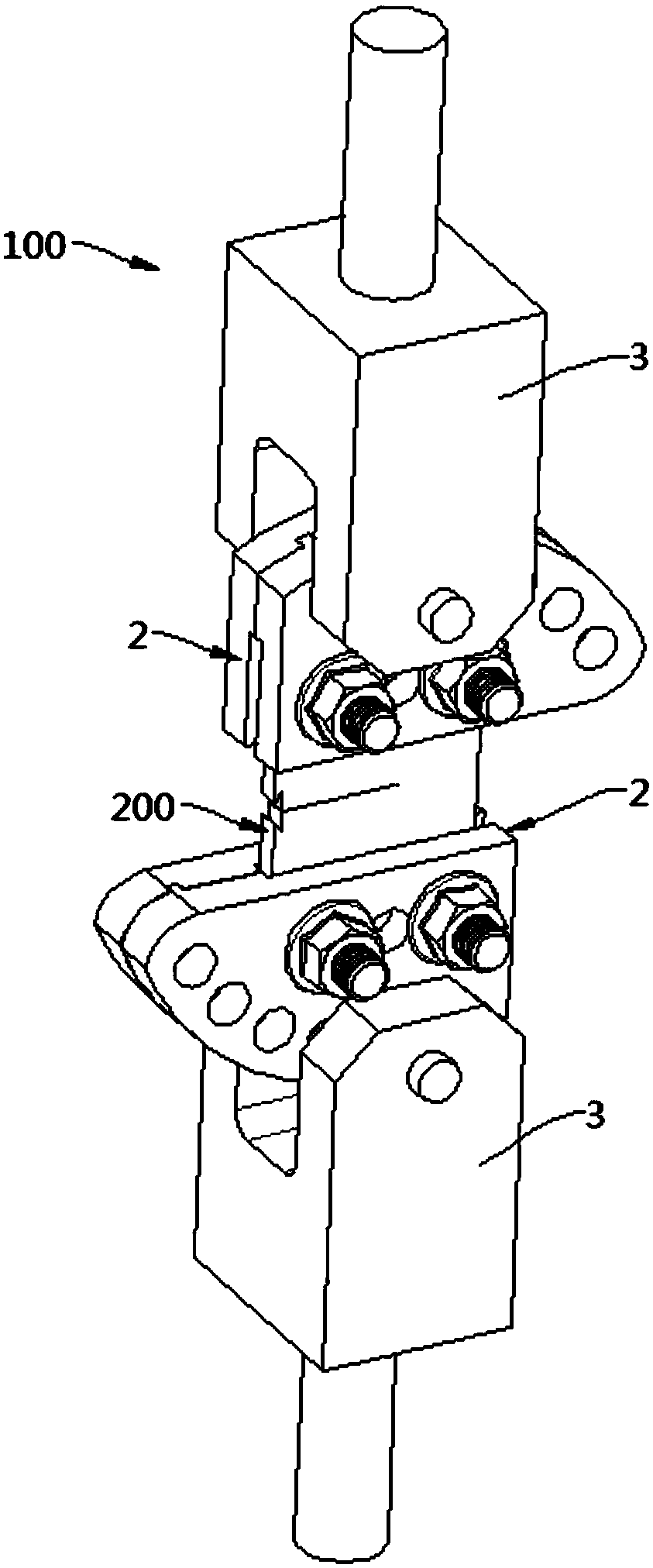

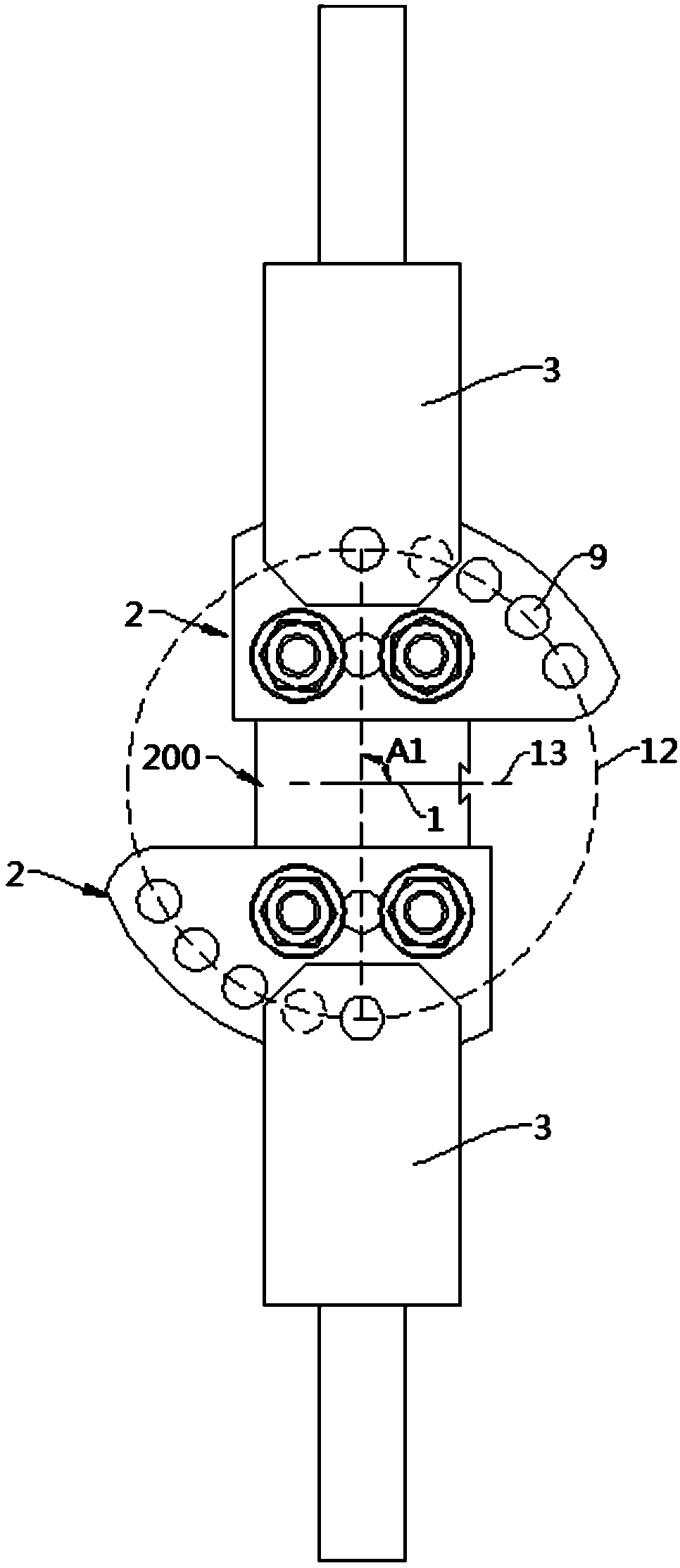

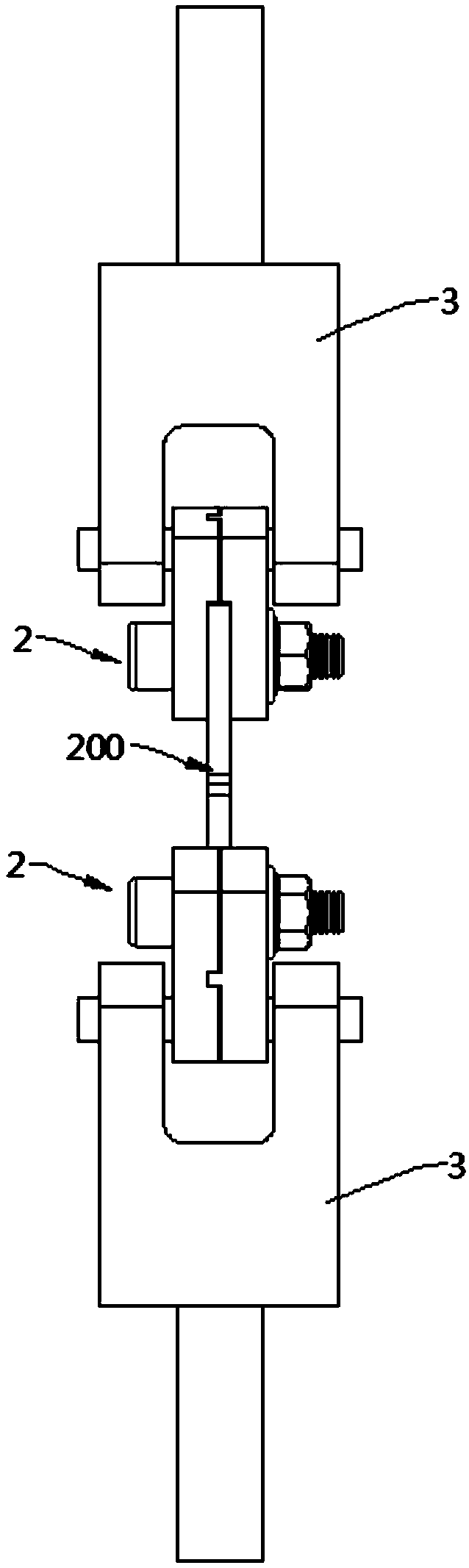

[0076] figure 1 Shows the I-II composite crack fatigue growth rate test device 100 and the connected sample 200 in the embodiment of the present invention; figure 2 Yes figure 1 The first perspective view; image 3 Yes figure 1 Second perspective view; Figure 4 for figure 2 Section view of Figure 5 for figure 1 Exploded view.

[0077] Image 6 A view under one embodiment of the sample 200 is shown. See Image 6 In this embodiment, the sample 200 is generally a plate-shaped structure, and a strip-shaped predetermined crack 1 extending inward from one side of the sample 200 is provided between its two ends. . The test device 100 can be used to apply an external tensile force perpendicular to the crack or obliquely intersecting with the crack to the sample 200, optionally a reciprocating external tensile force repeated multiple times, through the crack under the action of the tensile test load The data obtained by the measurement and processing of the expansion of the sample ca...

Embodiment approach

[0088] The following specifically introduces an embodiment of the I-II compound crack fatigue growth rate test device 100 test: Step (1): I-II compound crack fatigue growth test

[0089] After clamping a CTS sample 200 with the aforementioned I-II compound crack fatigue growth rate test method, start to load the test load with the size set to P and the number of cycles to N, and record the preset crack mouth under this load Opening displacement V, collect load P, crack mouth opening displacement V and cycle number N during the test, and save (P, V, N) experimental data.

[0090] According to the test load P-crack mouth opening displacement V curve, the flexibility C is obtained *

[0091]

[0092] Where C * Is the flexibility, P is the test load, V is the opening displacement of the 200 crack mouth of the CTS sample, C * It can be obtained by regression of the P-V test data obtained from the test, and the number of loading cycles N is collected during the test.

[0093] Step (2): I-II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com