Fused salt energy accumulation power station

An energy storage power station and molten salt technology, applied in the field of molten salt energy storage, can solve problems such as resource waste, system scrapping, poor detection of molten salt temperature, etc., and achieve the effect of improving thermal insulation performance and preventing cooling and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

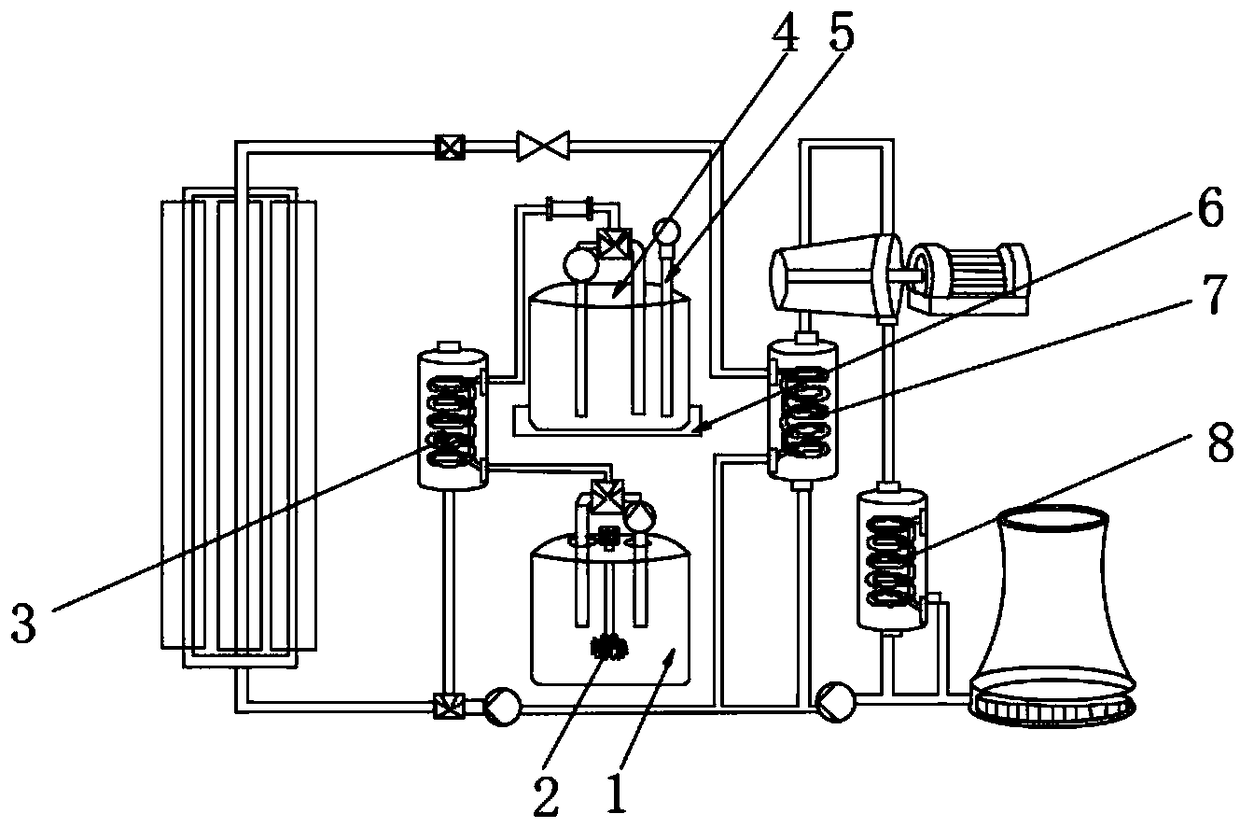

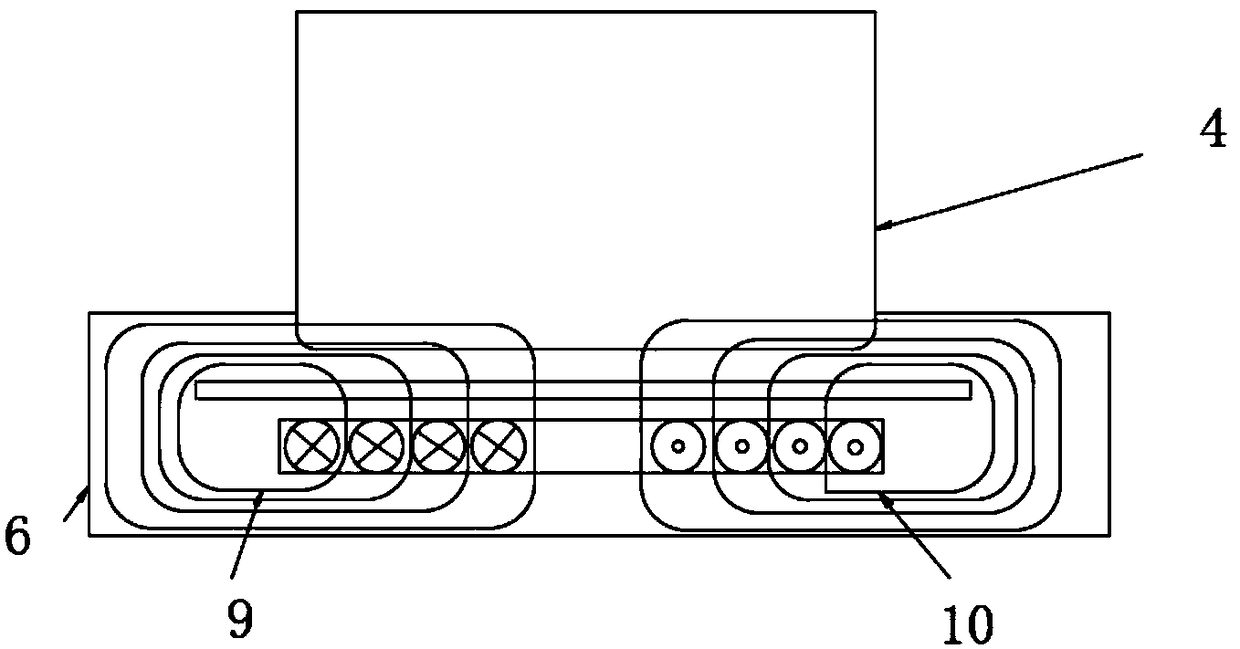

[0024] Example: refer to Figure 1-3 , the present invention provides a technical solution, a molten salt energy storage power station, including a low-temperature molten salt tank 1, a stirring impeller 2 is rotatably connected inside the low-temperature molten salt tank 1, and a high-temperature molten salt is installed above the low-temperature molten salt tank 1 Tank 4, the inside of the high temperature molten salt tank 4 is provided with a temperature sensor 5, and the bottom end of the high temperature molten salt tank 4 is provided with a high temperature molten salt tank base 6, and one side of the high temperature molten salt tank 4 is provided with a first heat exchanger 3 , and the other side of the high-temperature molten salt tank 4 is provided with a second heat exchanger 7, one side of the second heat exchanger 7 is provided with a condenser 8, and the inner bottom of the high-temperature molten salt tank base 6 is provided with a magnetic coil 9 One side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com