Split type instrument ball valve with long service life

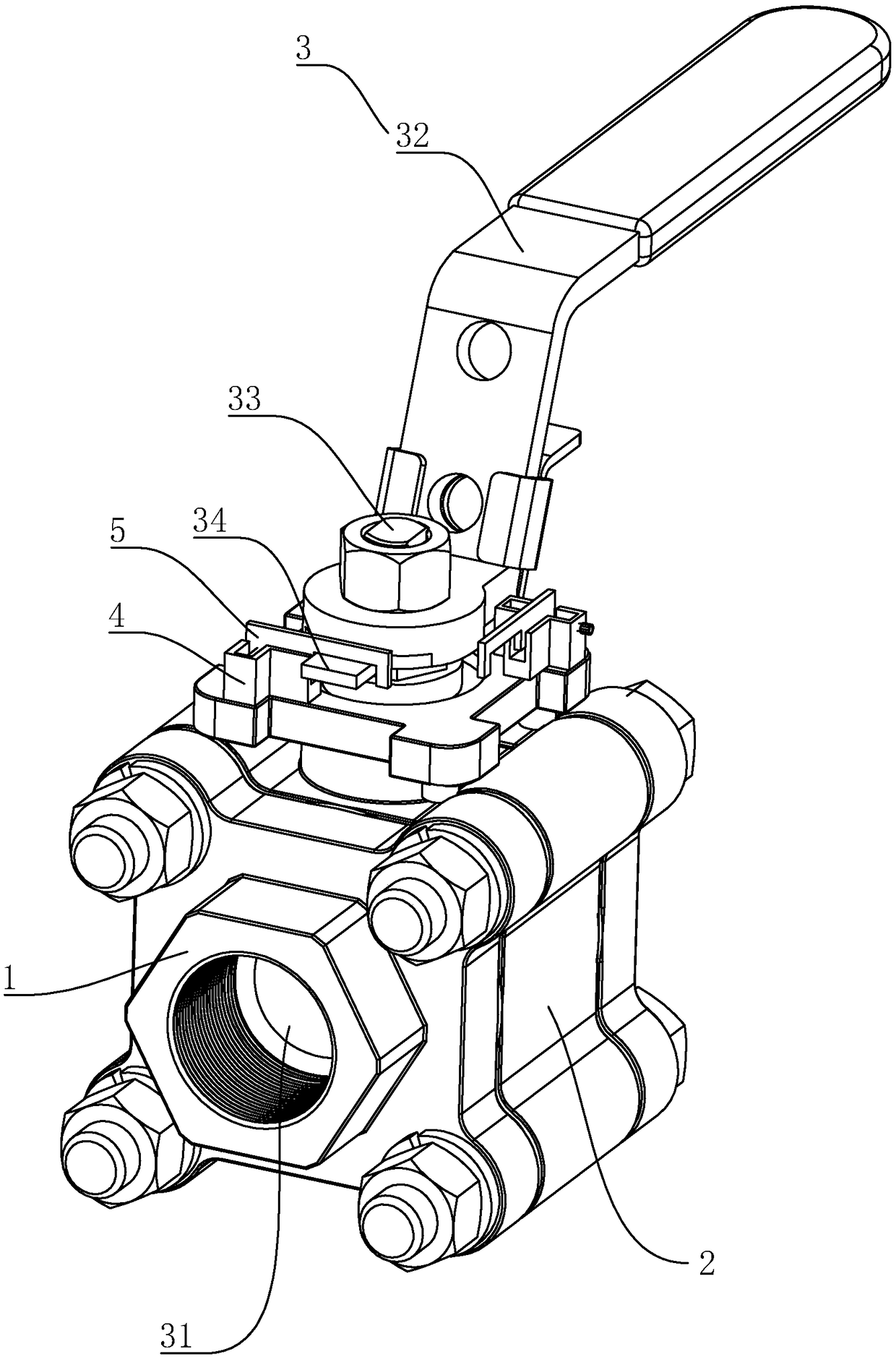

A split-type, long-life technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems affecting the transportation and use of media in the pipeline, control handle opening, bumping and other problems, and achieve the locking and unlocking process. Convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

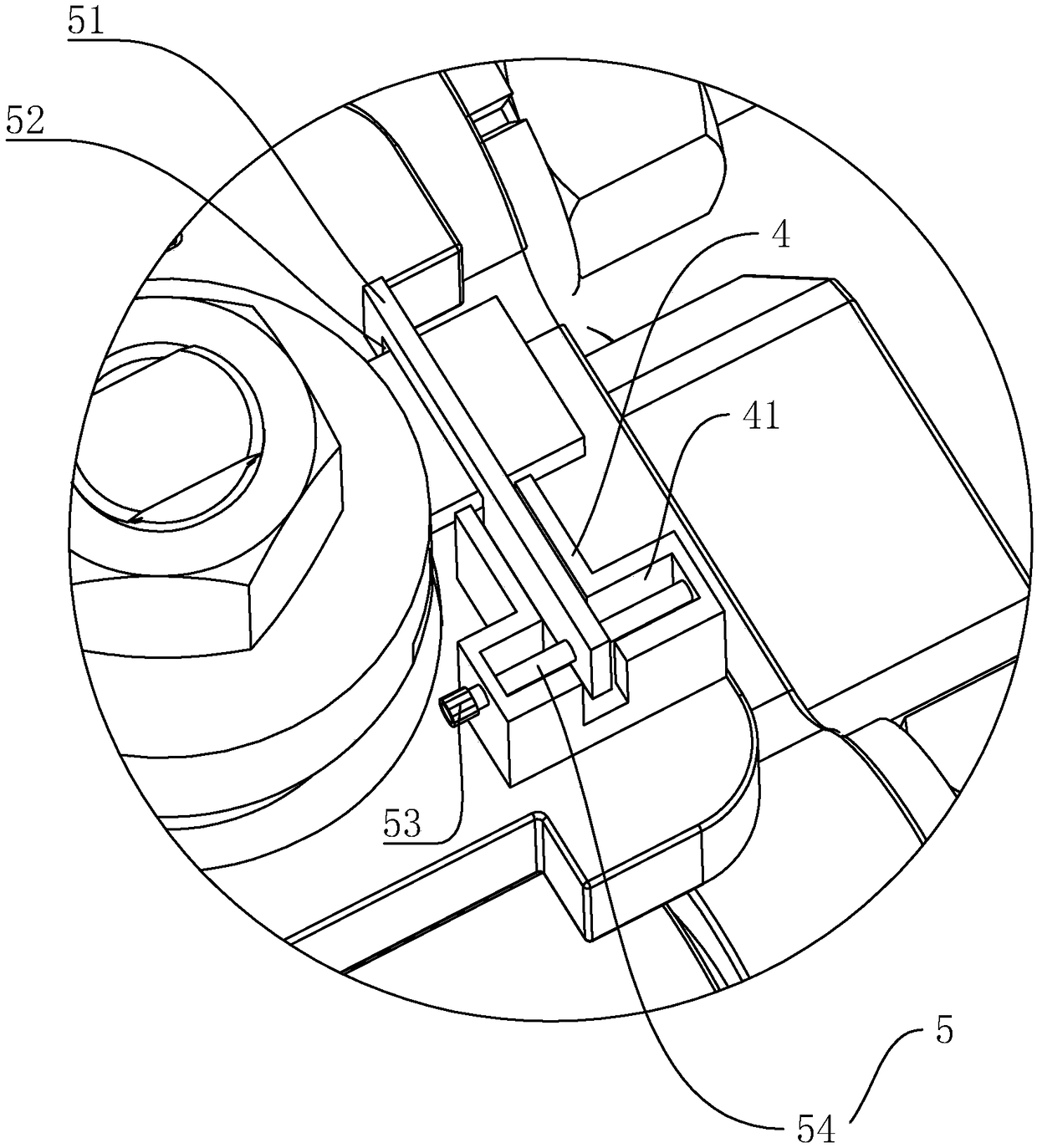

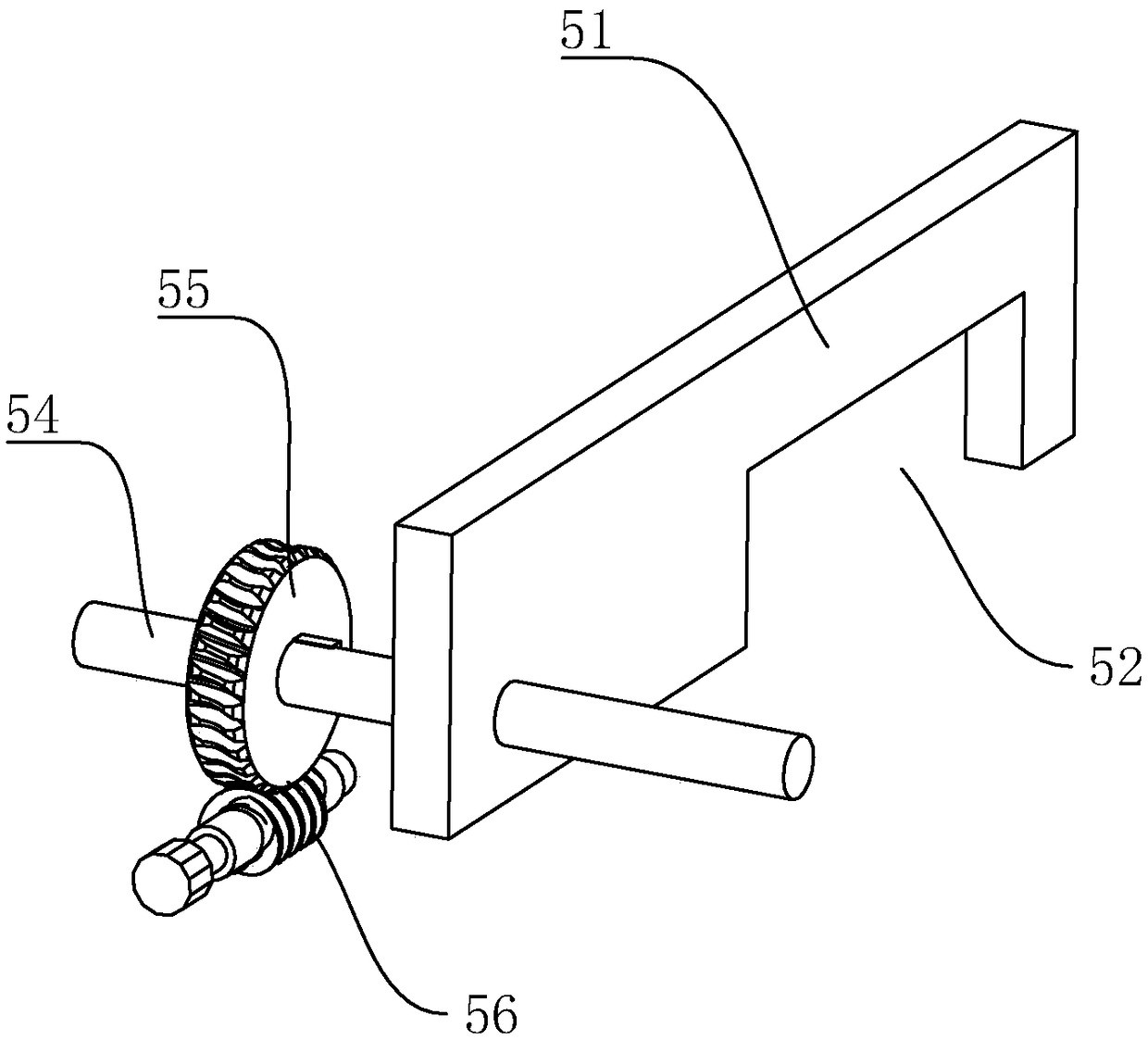

[0032] Embodiment 2, a high service life split type instrument ball valve, such as figure 1 and image 3 As shown, the difference from Embodiment 1 is that a locking worm gear 55 is fixed coaxially on the rotating shaft 54, and a locking worm 56 parallel to the rotating shaft 54 is rotatably connected in the locking groove 41. The locking worm gears 55 are engaged with each other. The end of the locking worm 56 facing away from the locking rod 34 penetrates the locking block 4 and extends to the outside world, and the end located at the outside is fixed with a rotating knob 57 .

[0033] When the control handle 32 is rotated to the designated position, the operator can turn the rotary knob 57 to drive the locking worm 56 and the locking worm wheel 55 to rotate, thereby linking the rotation shaft 54 and the locking rod 51 to rotate, to achieve the purpose of locking and fixing the control handle 32; The self-locking property of the worm gear can keep the rotating shaft 54...

Embodiment 3

[0034] Embodiment 3, a high service life split instrument ball valve, such as figure 1 and Figure 4 As shown, the difference from Embodiment 1 or 2 is that the locking member 5 includes an accommodating groove 42 opened in the middle of the locking block 4, and the accommodating groove 42 is slidably connected in the vertical direction with a locking plate 6, which locks the The ends of the plate 6 are correspondingly arranged in a hook shape, and the height of the locking plate 6 is greater than the height of the locking rod 34 .

[0035] like figure 1 and Figure 4 As shown, the locking member 5 includes a locking gear 62 rotatably connected to the accommodating groove 42 and a locking rack 61 fixed on the locking plate 6. The locking rack 61 and the locking gear 62 mesh with each other and are perpendicular to the Set on a horizontal plane, the locking gear 62 is rotatably connected in the accommodating groove 42 through the intermediate shaft 63 , and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com