Full-automatic regulation device for mine hoist brake shoe interval

A mine hoist and brake shoe clearance technology, which is applied in hoisting devices, slack regulators, mechanical equipment, etc., can solve problems such as hidden safety hazards, uncertain adjustment times and measurement times, and difficult manual detection, so as to improve accuracy and The effect of speed, reducing physical exertion, and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

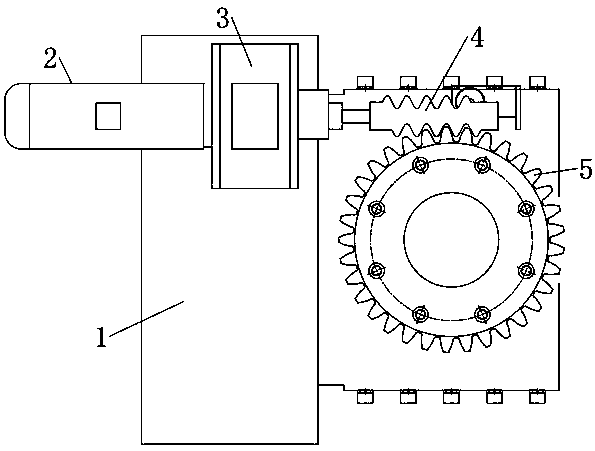

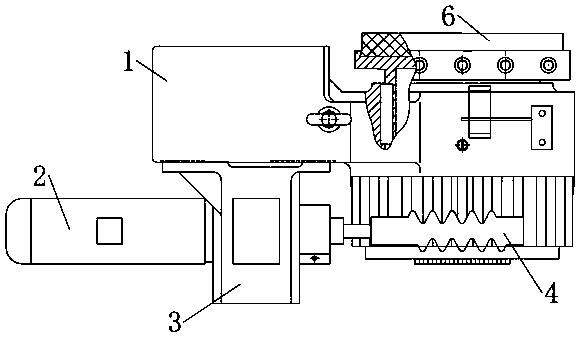

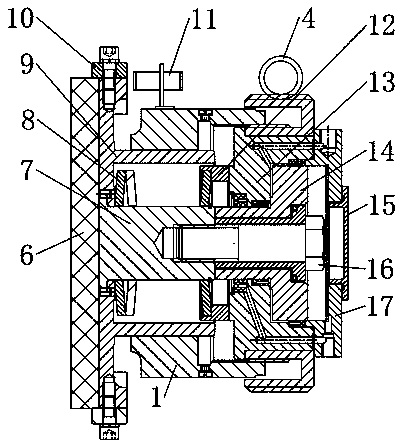

[0023] As shown in the figure, a fully automatic adjustment device for mine hoist brake shoe 6 gaps, including a brake body 1, a large ring gear 5, a worm 4, a miniature reducer, a miniature transmission motor 2 and a displacement sensor 11, and a brake body 1 One end of the inner diameter is threaded with a large ring gear 5, and the large ring gear 5 is engaged with the worm 4 arranged outside the brake body 1, and the tail of the worm 4 is connected with a miniature reducer, which is fixedly installed on the surface of the brake body 1. A micro-transmission motor 2 is connected to the micro-reducer, a displacement sensor 11 is installed outside the brake body 1, and a brake assembly is installed on the brake body 1.

[0024] The brake assembly includes a cylinder 9 arranged inside the brake body 1, the cylinder 9 is k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com