Totally-closed power transmission device used for coal mine explosion-proof electric rubber-wheel vehicle

A technology for power transmission and rubber-wheeled vehicles, which is applied to gear transmissions, transmissions, hydraulic brakes, etc., can solve the problems of restricting the passing ability and off-road ability of vehicles, unfavorable flexible layout of vehicles, and complex composition, etc. Strong adaptability, simple and convenient installation, disassembly and maintenance, low braking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

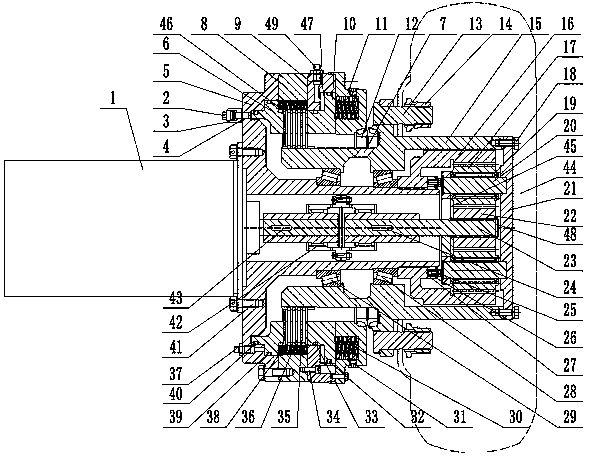

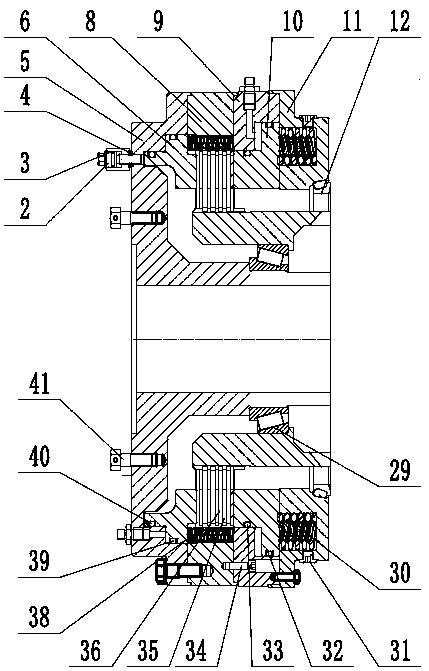

[0032] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0033] The present invention adopts the following technical solutions: a fully enclosed power transmission device for explosion-proof electric vehicles, which is characterized in that it includes a wheel-side transmission deceleration mechanism 45, a service brake mechanism 46 and a parking brake mechanism 47, and the wheel-side transmission deceleration mechanism 45 adopts Planetary one-stage deceleration form, service brake mechanism 46 adopts hydraulic brake, spring release multi-disc form, parking brake mechanism 47 adopts spring brake, hydraulic release safety type, explosion-proof motor 1 is driven by coupling 42 The wheel side transmission deceleration mechanism 45 is installed with the service brake mechanism 46 and the parking brake mechanism 47 after the wheel side transmission deceleration mechanism 45. The wheel side transmission deceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com