Board combination connecting buckle

A combined connection and buckle technology, applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of inability to support the plate, press the edge, easy installation errors, etc., and achieve the effect of improving the effect and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

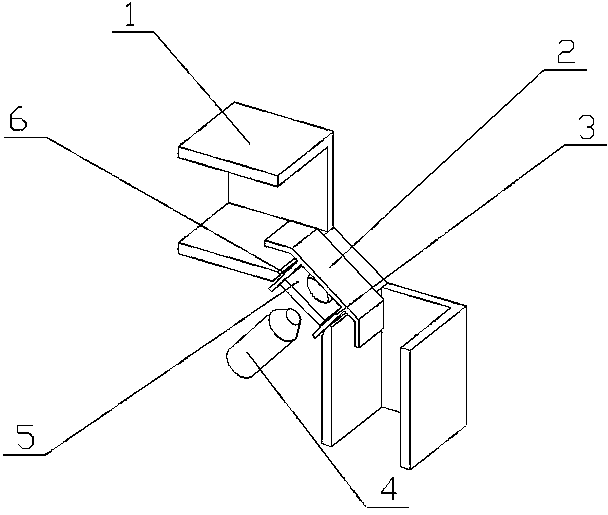

[0037] Such as figure 1 As shown: the joint buckle of the board combination of the present invention is realized in this way, including the corner mounting plate (5), the locking part and the pressure plate (1), and the corner mounting plate (5) is made of metal plates twice consecutively It is bent and forms three bending parts, the locking part is placed on the bending part in the middle of the corner mounting plate (5), and the two pressure plates (1) are respectively placed on the outside of the corner mounting plate (5) on the two bends of the

[0038] The extension lines of the center lines of the two outer bending parts of the corner mounting plate (5) are perpendicular to each other;

[0039] The two outer bending parts of the corner mounting plate (5) have the same length and are twice the length of the middle bending part, which can increase the supporting surface for the plate, and push the push in with less screwing. The plate (2) is pushed to the plate for clamp...

Embodiment 2

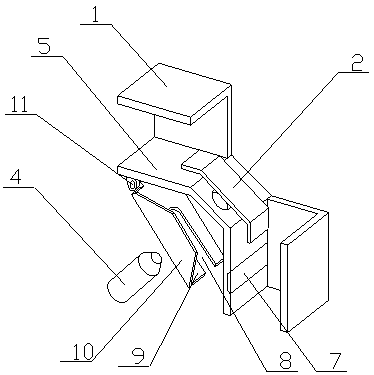

[0056] Such as figure 1As shown, the bottom of the corner mounting plate (5) is equipped with a protective part, and the protective part is composed of an opening slot (8), a lower baffle (9), a side baffle (10) and a hinged frame (11). One end of the lower baffle (9) is hinged to the bottom of one end of the corner mounting plate (5) through the hinged frame (11). The lower baffle (9) is provided with an opening slot (8), and the opening is located 9) At the other end, two side baffles (10) are respectively placed on both sides of the lower baffle (9). ) and the lower baffle (9) are made of metal materials;

[0057] A magnetic strip (7) is placed on the corner mounting plate (5) and is close to the other end of the corner mounting plate (5);

[0058] After the wooden boards are compressed and fixedly connected by the locking part, the lower baffle (9) is rotated, and the lower baffle (9) drives the side baffles (10) on both sides to move, so that the edges of the two side b...

Embodiment 3

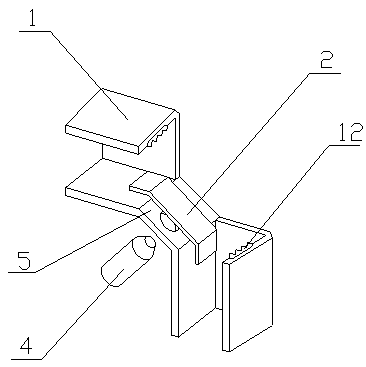

[0060] Such as image 3 As shown: the pressure plate (1) has an anti-skid tooth plate (12) inside, and corresponds to the corresponding part of the corner mounting plate (5);

[0061] One side of the anti-slip tooth plate (12) is equipped with multiple groups of teeth at equal distances, each group of teeth is composed of at least five teeth, and there is a gap between two adjacent teeth in the same group, and the surface of the teeth is provided with Rubber mat.

[0062] After the wooden boards are compressed and connected by the locking part, the anti-slip tooth plate (12) is attached to the surface of the wooden board, and the friction force between the anti-skid toothed plate (12) and the wooden board is relatively large, and when the wooden board is pressed tightly, it can prevent The wooden board slides in the installation groove to ensure the connection area between the wooden board and the connecting buckle, as well as the load-bearing capacity, and thus better safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com