Preparation method of flame-retarding and heat-insulating foamed polyurethane

A foamed polyurethane, flame retardant and thermal insulation technology is applied in the preparation of flame retardant and thermal insulation foamed polyurethane, and in the field of new environmentally friendly building materials. Improve mechanical strength and structural stability, stable performance, and improve the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1

[0022] A preparation method of flame-retardant thermal insulation foamed polyurethane includes the following steps:

[0023] Mix the polyether polyol and polyester polyol according to the proportion, vacuum dehydration, heat up to 39℃ and stir to react, then put in the flame retardant, stir at 1200r / min for 50-60min, then add epoxy soybean oil, extend chain Stabilizer, stabilizer, catalyst, stir at 1000r / min for 15-20min, then add basalt fiber, continue to stir for 5min, then treat at 0.2Mpa for 5-10min, add the foaming agent storage tank, and then add the foaming agent Add isocyanate and isocyanate to foaming machine separately, use high-pressure foaming machine to foam, keep the mold temperature at 50-85℃, and shape to make foamed polyurethane;

[0024] The raw materials are as follows by weight: 52 parts polyether polyol, 65 parts polyester polyol, 80 parts isocyanate, 3.5 parts epoxy soybean oil, 5 parts flame retardant, 4.2 parts chain extender, 0.2 parts sta...

Example Embodiment

[0033] Example 2

[0034] Compared with Example 1, it is made of the following raw materials: 55 parts of polyether polyol, 62 parts of polyester polyol, 100 parts of isocyanate, 4 parts of epoxy soybean oil, 6 parts of flame retardant, and 5.2 parts of chain extender Parts, 0.22 parts of stabilizer, 24 parts of basalt fiber, 0.9 parts of foaming agent, 1.4 parts of catalyst. Other steps are as in Example 1.

Example Embodiment

[0035] Example 3

[0036] Compared with Example 1, it is made of the following raw materials: 55 parts of polyether polyol, 63 parts of polyester polyol, 105 parts of isocyanate, 3.6 parts of epoxy soybean oil, 7 parts of flame retardant, 4 parts of chain extender -7 parts, 0.2 parts of stabilizer, 25 parts of basalt fiber, 0.9 parts of foaming agent, 1.3 parts of catalyst. Other steps are as in Example 1.

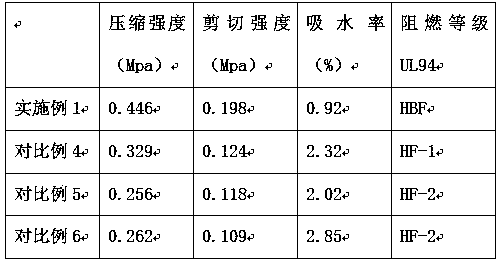

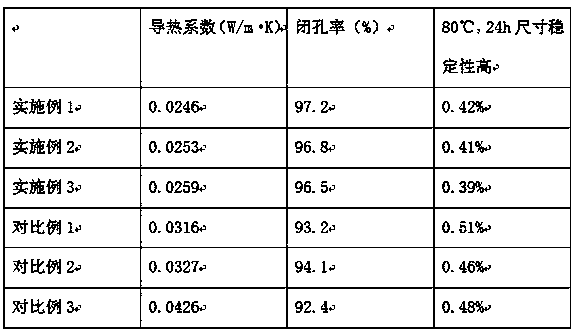

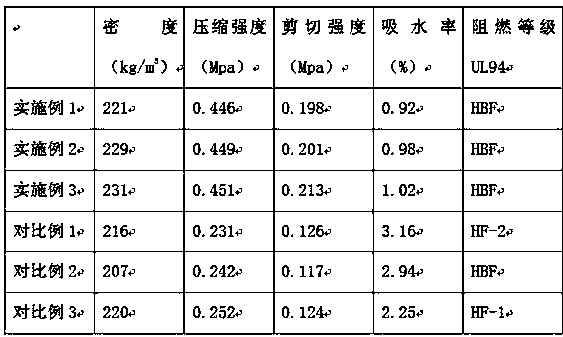

[0037] In order to verify the influence of the flame retardant and basalt fiber in this application on the performance of the foamed polyurethane in this application, this application sets the following control group to compare the performance of the prepared polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com