A kind of wear-resistant castable and its preparation and use method

A castable, a technology in the circumferential direction, which is applied in the preparation and construction of wear-resistant castables for the CDQ cooling section, and can solve the inconvenience of wear resistance of lining bricks in the working layer of CDQ, the inability to reflect high temperature performance, and the wear resistance. Insufficient and other problems, to achieve the effect of good thermal shock stability, strong wear resistance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

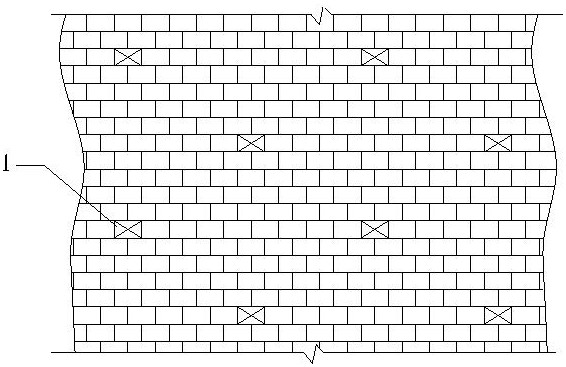

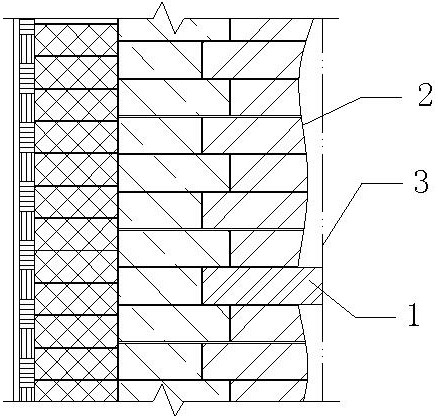

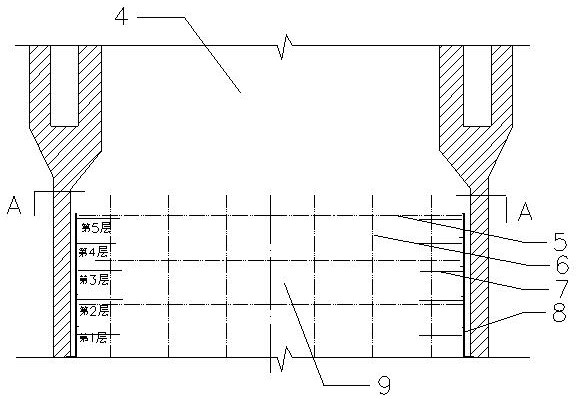

Image

Examples

Embodiment 1

[0053] A wear-resistant castable, which is used in the middle and low temperature region of the lower part of the cooling section of the dry quenching furnace, and the temperature range is 200-700 ° C. The raw material components and weight percentages are: aggregate 70-74%, matrix 24-30%, Stainless steel heat-resistant fiber 1.4 to 2.0%.

[0054] The composition and weight percentage of the aggregate are: 60-65% of high-purity and low-iron synthetic mullite, and 8-10% of super-grade silicon carbide; the gradation of the aggregate is: high-purity and low-iron synthetic mullite Particle size > 3mm, and ≤ 6mm, accounting for 10-12%, high-purity low-iron synthetic mullite particle size > 1mm, and ≤ 3mm, accounting for 26-30%, high-purity low-iron synthetic mullite The particle size of stone ≤ 1mm accounts for 20-22%, the particle size of super silicon carbide > 1mm and ≤ 3mm accounts for 3%, and the particle size of super silicon carbide ≤ 1mm accounts for 5%.

[0055] The compo...

Embodiment 2

[0058] In this example, the wear-resistant castable components are used: mullite aggregate (3mm<its particle size≤6mm) 1.2Kg, mullite aggregate (1mm<its particle size≤3mm) 2.3Kg, silicon carbide aggregate (1mm<its particle size≤3mm) 0.4Kg, silicon carbide (its particle size≤1mm) 0.6Kg, stainless steel heat-resistant fiber 0.15Kg, high-purity silicon micropowder 0.5Kg, silicon carbide fine powder 0.5Kg, high-purity aluminate 0.5Kg, active α-A12O3 0.4Kg, adding water 0.6Kg. All the other are with embodiment 1.

Embodiment 3

[0060] The preparation method of wear-resistant castable of the present invention comprises the following steps:

[0061] (1) According to the weight percentage of aggregate and fine powder, use high-purity and low-iron synthetic mullite and super silicon carbide as raw material components, add α-A1 2 o 3 Ultra-fine powder, high-purity silica powder, using pure calcium aluminate cement as binder, mix in cement mortar mixer 2 - 3 minutes.

[0062] (2) Add stainless steel heat-resistant fiber to the mixture prepared in step (1), and continue to stir and mix 2 - 3 minutes.

[0063] (3) Slowly add a certain amount of water to the mixture prepared in step (2) and continue stirring 2 - 3 minutes to obtain a uniform castable.

[0064] (4) Detection of wear-resistant castable samples

[0065] 1) Prepare wear-resistant castable samples with castables, vibrate on a vibrating table to form wear-resistant castable samples of 40mm×40mm×160mm, 100mm×l00mm×30mm, 75mm×100mm×100mm, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com