A kind of superfine inorganic grouting material for tunnel inverted arch and preparation method thereof

A technology for grouting materials and tunnels, which is applied in the field of superfine inorganic grouting materials for tunnel inverts and its preparation. It can solve the problems of decreased consolidation strength, poor stability, and rough cement slurry, etc., and achieves improved service life and good impermeability. , the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

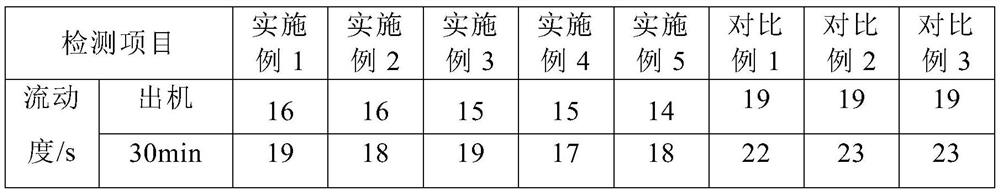

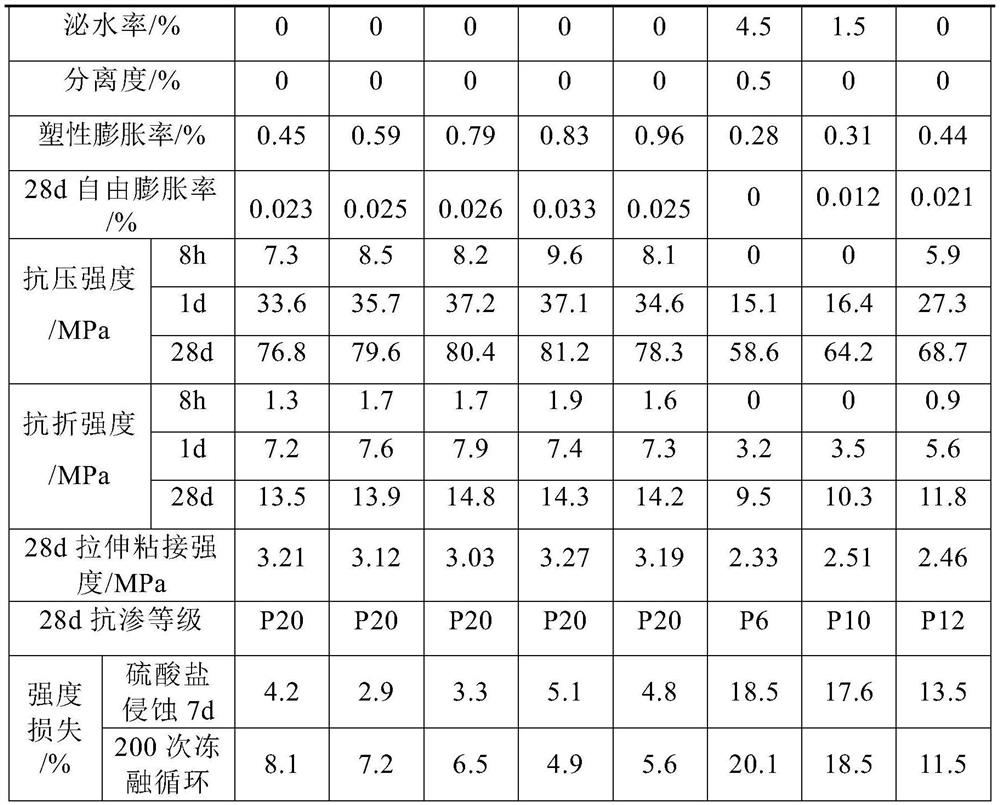

Examples

Embodiment 1

[0034] An ultrafine inorganic grouting material for tunnel inverts, the preparation method of which comprises the following steps:

[0035] 1) Weigh each raw material according to the proportion, each raw material and its dosage include: 75kg of superfine cementitious material (58.5kg of ordinary portland cement, 16.5kg of low alkalinity sulphoaluminate cement), 16.06kg of mineral filler (fine talc powder 14.36kg, sepiolite powder 1.7kg), composite expansion agent 2.5kg (calcined magnesia 2kg, ammonium nitrite 0.5kg), fluid volume stabilizer 0.04kg (sodium polyacrylate 0.02kg, kelp root 0.02kg), and 0.5kg of membrane modifier (0.5kg of carboxymethyl starch), 0.43kg of water reducer, 0.02kg of defoamer, 0.35kg of dispersant, 0.1kg of anti-seepage and water repellent, and 5kg of nano-enhanced components;

[0036] 2) Put the weighed mineral filler, composite expansion agent, flow volume stabilizer, film-forming modifier, water reducer, defoamer, dispersant, anti-seepage water repel...

Embodiment 2

[0039] An ultrafine inorganic grouting material for tunnel inverts, the preparation method of which comprises the following steps:

[0040] 1) Weigh each raw material according to the proportion, each raw material and its dosage include: 78kg of superfine cementitious material (62.5kg of ordinary portland cement, 15.5kg of low alkalinity sulphoaluminate cement), 12.62kg of mineral filler (fine talc powder 11.12kg, sepiolite powder 1.5kg), composite expansion agent 3.7kg (calcined magnesia 3kg, ammonium nitrite 0.7kg), fluid volume stabilizer 0.05kg (sodium polyacrylate 0.03kg, kelp root 0.02kg), and 0.7kg of membrane modifier (0.7kg of phosphate starch), 0.52kg of water reducer, 0.03kg of defoamer, 0.3kg of dispersant, 0.08kg of anti-seepage and water repellent, and 4kg of nano-enhanced components;

[0041] 2) Put the weighed mineral filler, composite expansion agent, flow volume stabilizer, film-forming modifier, water reducer, defoamer, dispersant, anti-seepage water repelle...

Embodiment 3

[0044] An ultrafine inorganic grouting material for tunnel inverts, the preparation method of which comprises the following steps:

[0045] 1) Weigh each raw material according to the proportion, and each raw material and its dosage include: 83kg of superfine cementitious material (66kg of ordinary Portland cement, 17kg of low-alkalinity sulphoaluminate cement), 7.18kg of mineral filler (5.98kg of fine talc powder kg, sepiolite powder 1.2kg), composite expansion agent 4.9kg (calcined magnesia 4kg, ammonium nitrite 0.9kg), fluid volume stabilizer 0.06kg (sodium polyacrylate 0.03kg, kelp root 0.03kg), film-forming 0.9kg of agent (0.4kg of carboxymethyl starch, 0.5kg of phosphate starch), 0.61kg of water reducer, 0.04kg of defoamer, 0.25kg of dispersant, 0.06kg of anti-seepage and water repellent, and 3kg of nano-enhanced components;

[0046] 2) Put the weighed mineral filler, composite expansion agent, flow volume stabilizer, film-forming modifier, water reducer, defoamer, dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com