Stacking transferring mechanical device with flexible clamping gripper

A flexible clamping and mechanical device technology, applied in the stacking, transportation and packaging of objects, conveyor objects, etc., can solve the problems of high production cost, high labor intensity of employees, and many human factors, and achieve convenient operation and structure. Simple, efficient and stacking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

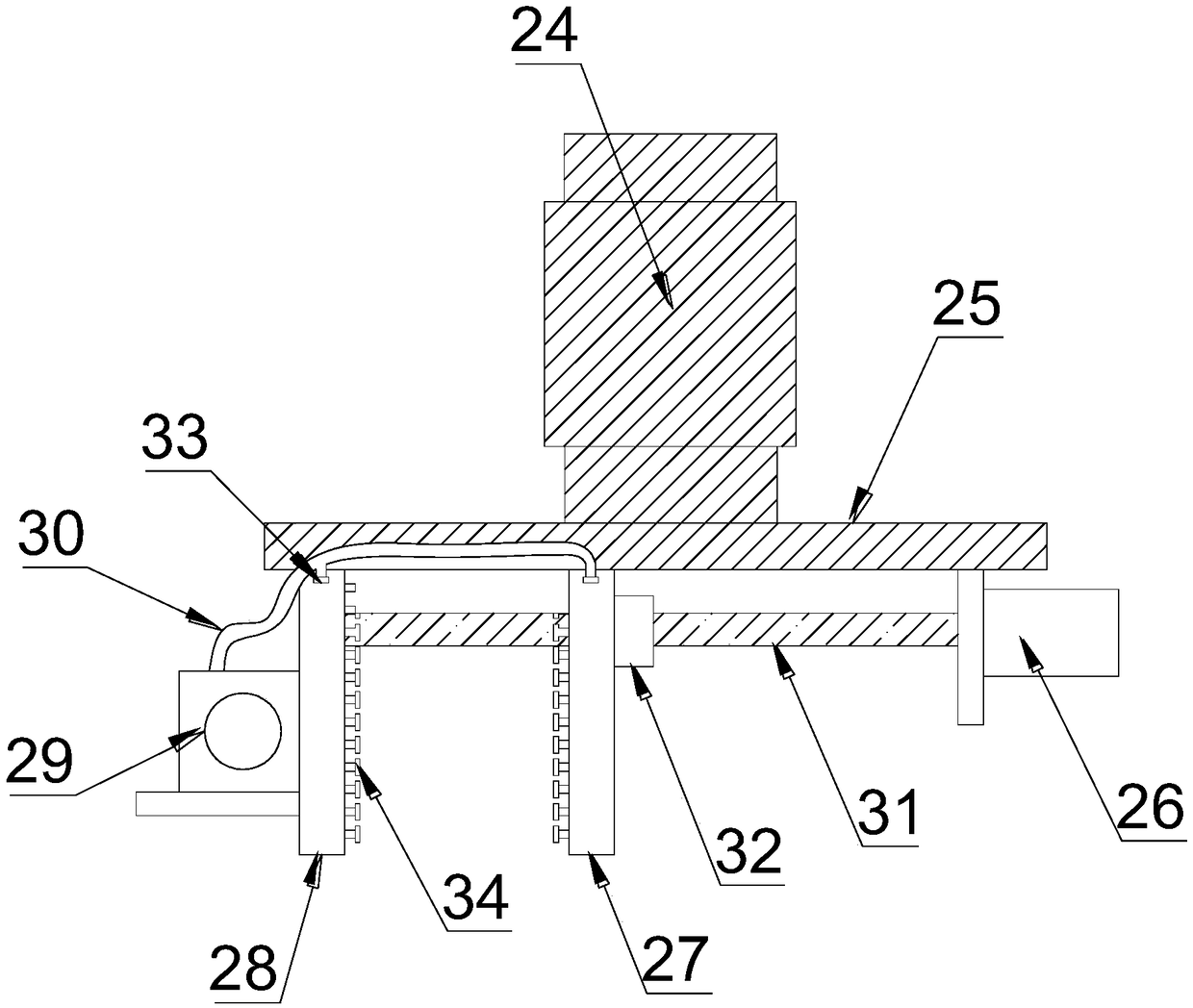

[0029] see Figure 1 ~ Figure 3 , in this embodiment, a stacking transfer mechanical device with flexible clamping mechanical claws includes an X-direction moving mechanism, a Y-direction moving mechanism, a Z-direction moving mechanism and a flexible clamping mechanical claw, and the X-direction moving mechanism is set At the bottom of the Z-direction moving mechanism, the Z-direction moving mechanism is arranged slidingly along the X-direction moving mechanism, the Y-direction moving mechanism is arranged on the side of the Z-direction moving mechanism, and the Y-direction moving mechanism is arranged slidingly along the Z-direction moving mechanism. It is installed on the bottom side of the Y-direction moving mechanism and slides along the Y-direction moving mechanism.

[0030] The X-direction moving mechanism includes an X-direction lead screw 13, an X-direction motor 14, an X-direction slider 15, an X-direction chute 16 and an X-direction slide rail 17, and the middle par...

Embodiment 2

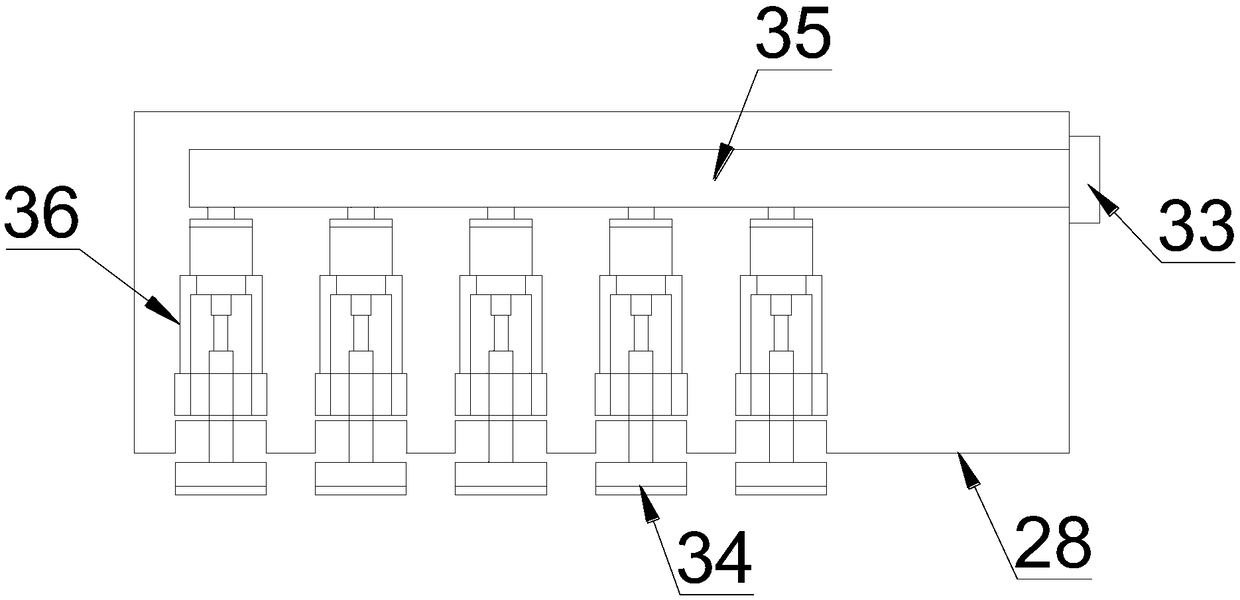

[0037] see Figure 1 ~ Figure 3 , in this embodiment, a stacking and transporting mechanical device with flexible clamping mechanical claws, the pressure pump 29 is a hydraulic pump, pressurized by hydraulic oil, so that the right clamping claw 27 or the left clamping claw Several flexible pressing fingers 34 on 28 are evenly stressed when clamping, and the rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com