Micro clamping finger air cylinder and drive method thereof

A finger-clamping cylinder and driving method technology, applied in the field of automation, can solve the problems of complexity, many cylinder components, inconvenient maintenance, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

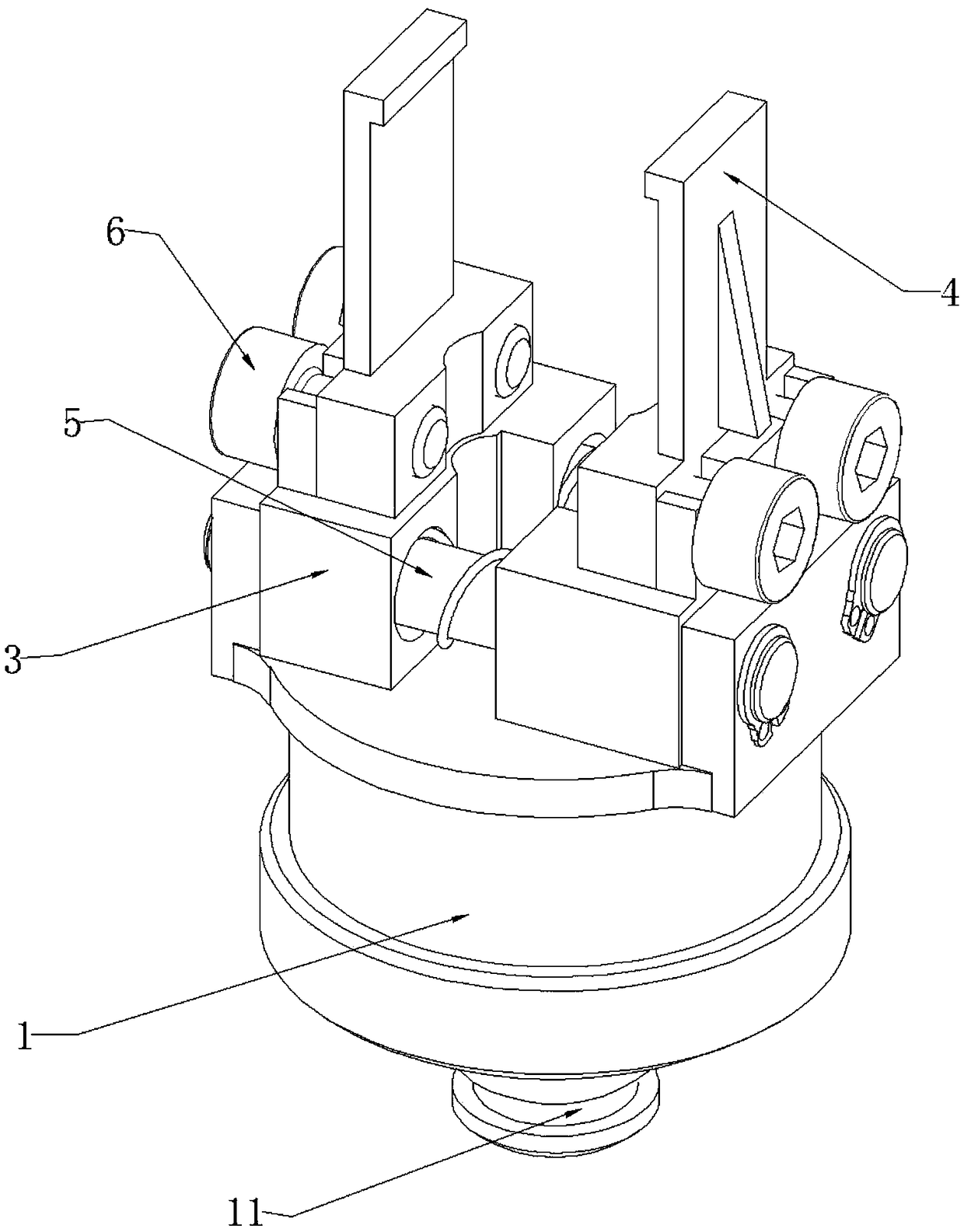

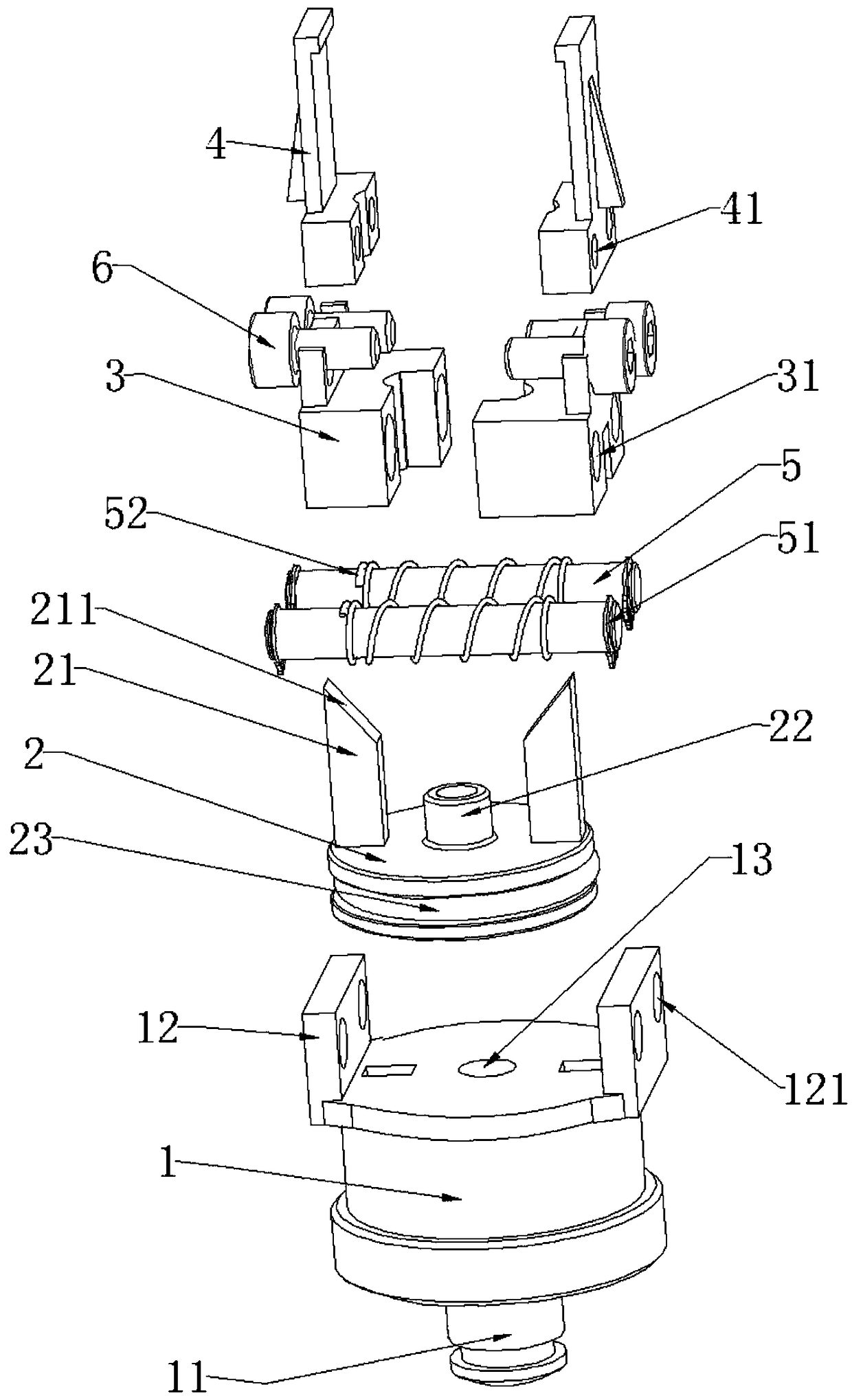

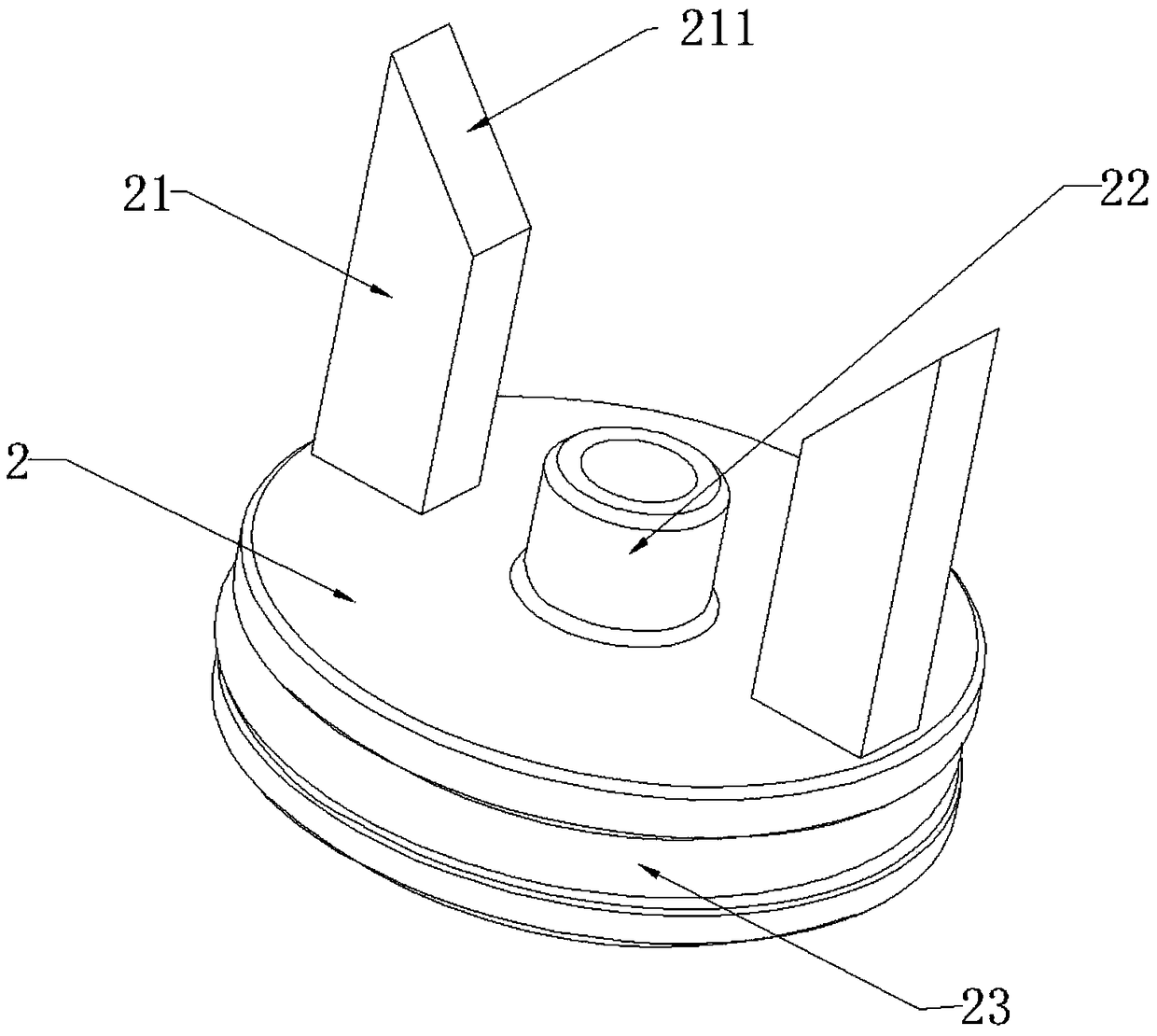

[0039] see figure 1 and figure 2 , the present invention discloses a miniature clamping finger cylinder, comprising a cylinder body 1, a piston body 2, a clamping finger slide seat 3 and a clamping finger 4, the piston body 2 is arranged inside the cylinder body 1, and the piston body 2 is provided with The movement rod 21 on the surface of the piston body, the lower end of the movement rod 21 is fixed on the piston body 2, the upper end of the movement rod 21 is a slope structure 211; A slope structure in the opposite direction corresponding to the slope structure 211 of the movement rod 21 is provided, and a fixing hole 31 is provided on the finger slide seat 3, and the finger slide seat 3 is sleeved on the guide shaft 5 by using the fixing hole 31, so that the clip The finger slider 3 moves on the guide shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com