Automatic production line of G-series high-speed train sleeper stirrup

An automatic production line, stirrup technology, applied in auxiliary devices, chucks, other manufacturing equipment/tools, etc., can solve problems such as low production efficiency and unguaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

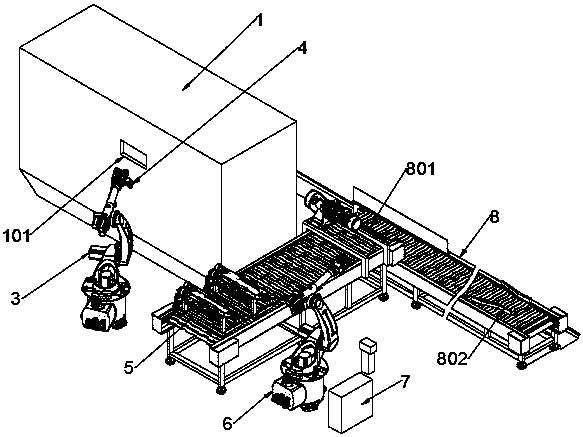

[0020] The invention discloses a stirrup automatic welding system for connecting a stirrup bending machine and a truss intelligent assembly system, which belongs to a part of a sleeper automatic production line. The welding system of the embodiment is such as figure 1 Shown, including:

[0021] Bending machine 1, used to bend steel bars into rectangular stirrups 2;

[0022] The reclaiming robot 3 and the grabbing tool 4 installed at the end of the reclaiming robot are used to grab the stirrups 2 processed by the bending machine 1 from the discharge port 101 and place them on the welding table 5;

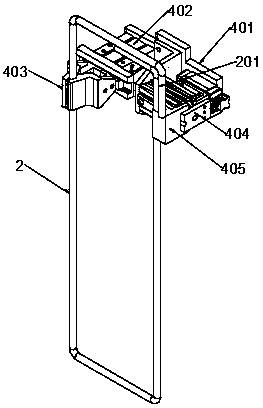

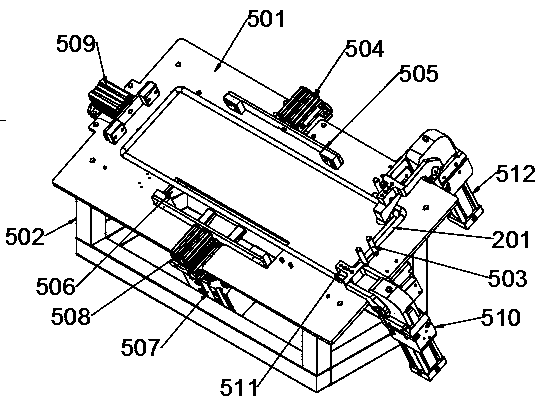

[0023] The grasping tool 4 includes a mounting plate 401 mounted on the reclaiming robot 3, one end of the mounting plate 401 is mounted with a grasping cylinder 402, the grasping cylinder 402 is mounted with a grasping clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com