Power distribution cabinet body welding equipment

A technology of welding equipment and power distribution cabinet, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of people's health impact, reduce welding efficiency, and no protective measures, so as to save labor force, Improve work efficiency and ensure physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

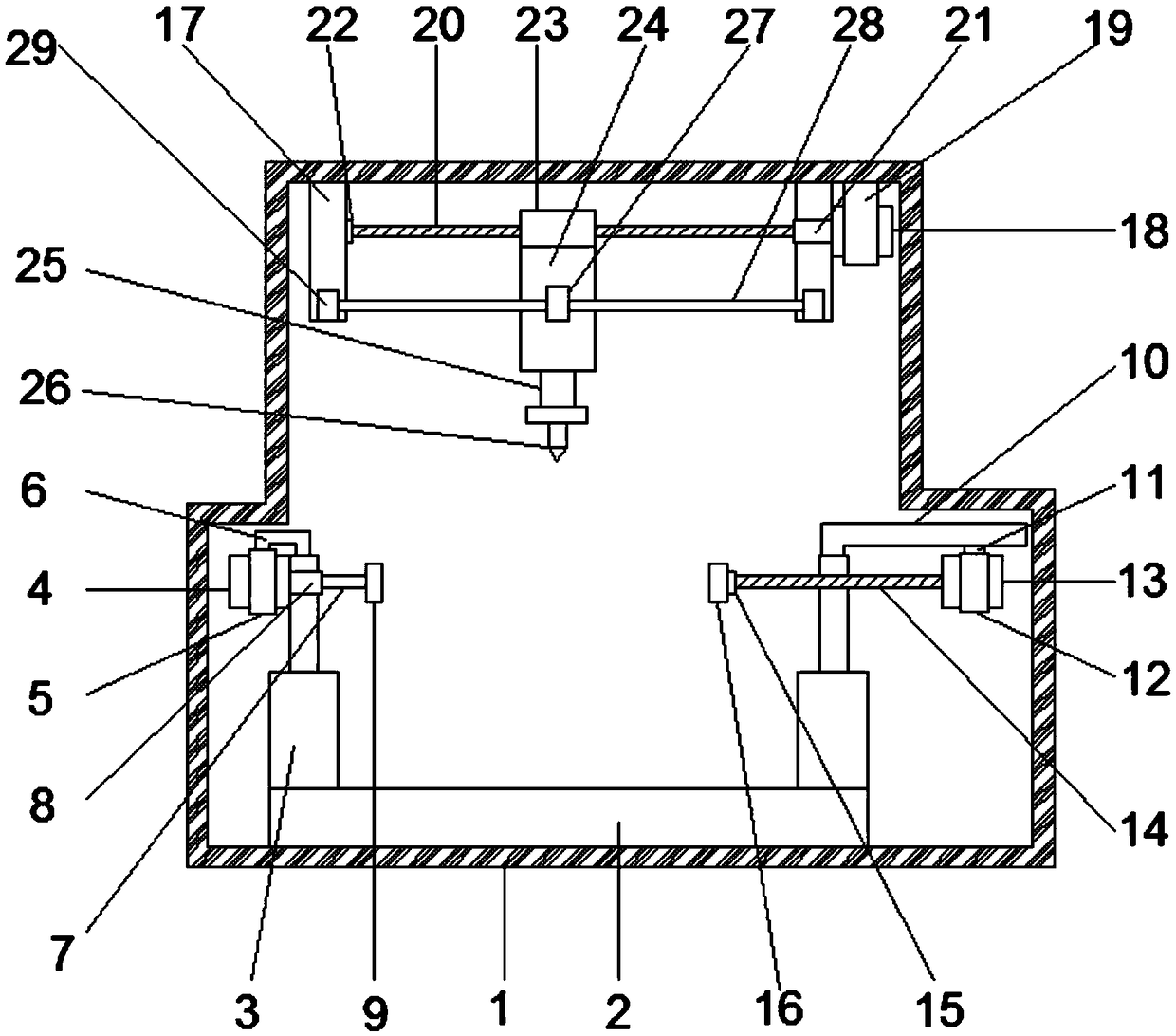

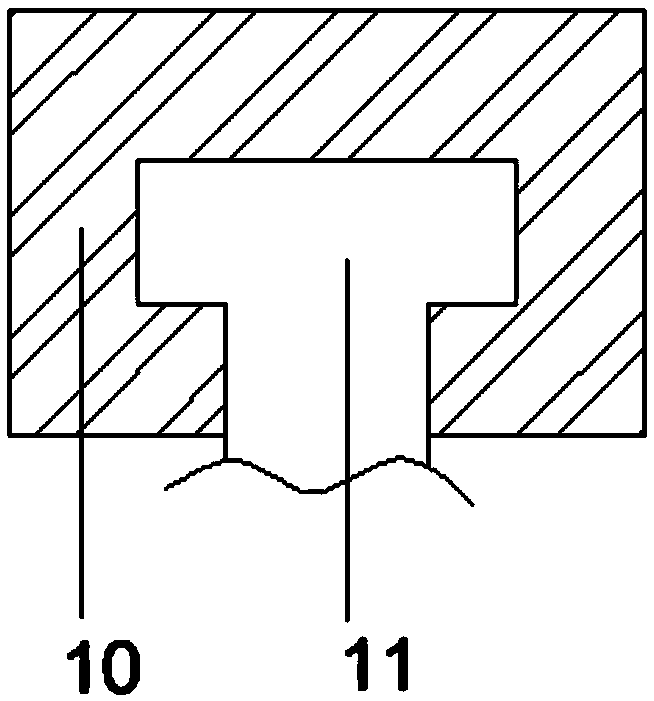

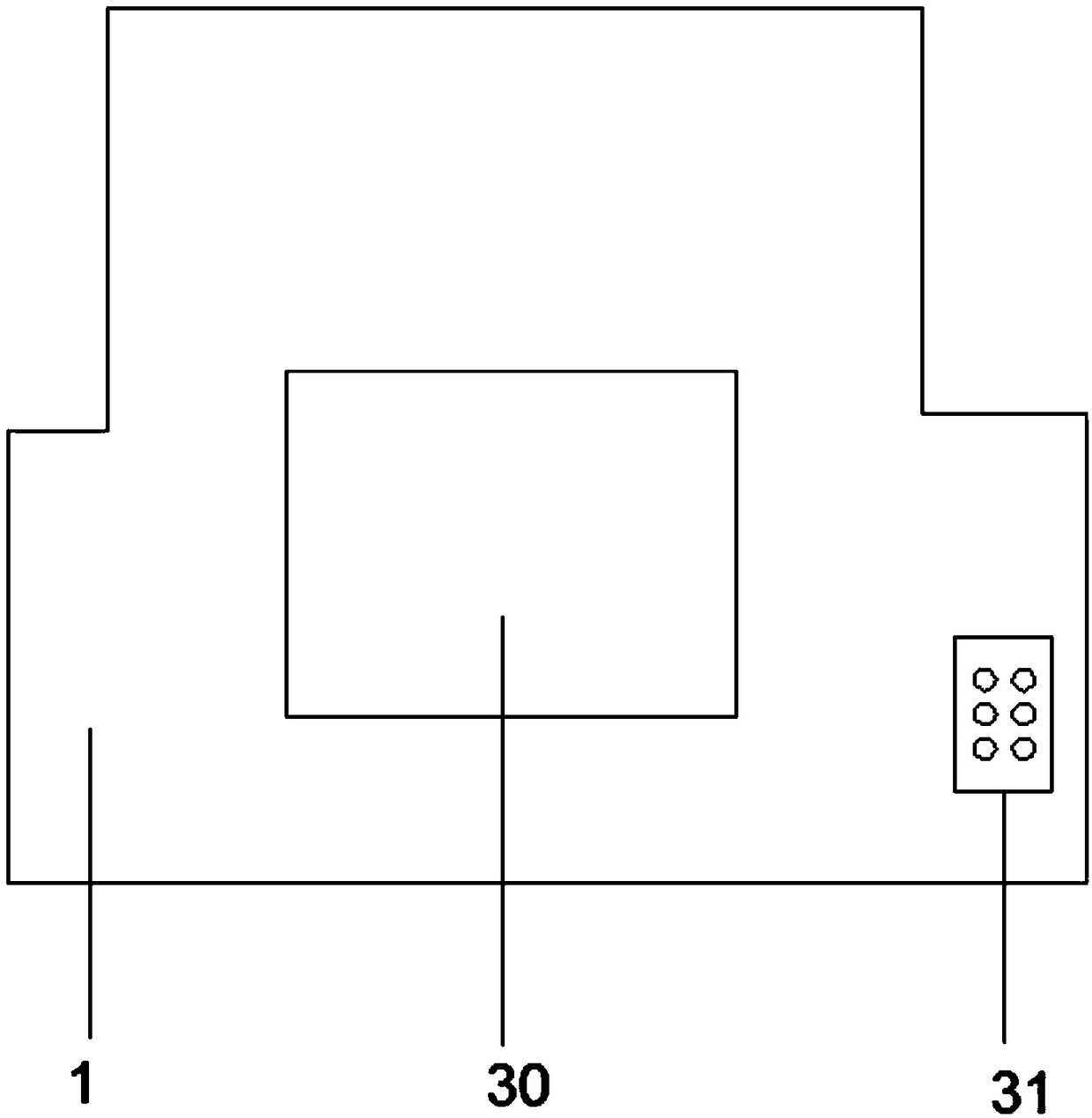

[0020] Such as Figure 1-Figure 3 As shown, a welding equipment for a power distribution cabinet proposed by the present invention includes a casing 1, a hydraulic telescopic assembly 3, a first fixing member 9, a second screw rod 20, and a welding gun 26, and the inner bottom of the casing 1 is provided with a base 2, and the upper end of the base 2 is symmetrically provided with a hydraulic telescopic assembly 3 on the left and right sides, the left upper end of the left hydraulic telescopic assembly 3 is provided with a first motor 4, and the middle part of the right side of the first motor 4 is provided with a rotating shaft 7, and the right end of the rotating shaft 7 runs through The hydraulic telescopic assembly 3, and the right end of the rotating shaft 7 is provided with a first fixing member 9, the upper end of the right hydraulic telescopic assembly 3 is provided with a T-shaped chute 10, and the lower end of the T-shaped chute 10 is slidably connected to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com