Solid wire gas shielded vertical upward welding method

A solid welding wire and vertical welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems affecting the automation degree of storage tank projects, wall plate deformation, large current and voltage of gas-electric vertical welding, etc., and reduce welding Low cost, small heat input, guaranteed welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen understanding of the present invention, below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0017] A method for gas-protected vertical upward welding of a thin-walled solid welding wire provided in this embodiment includes the following steps:

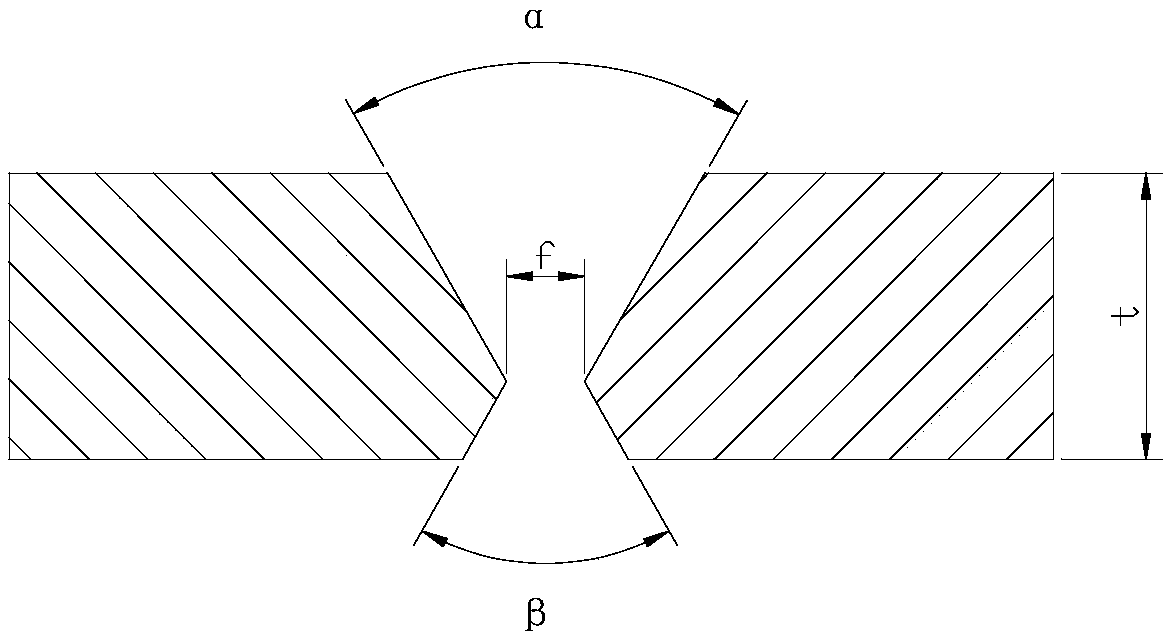

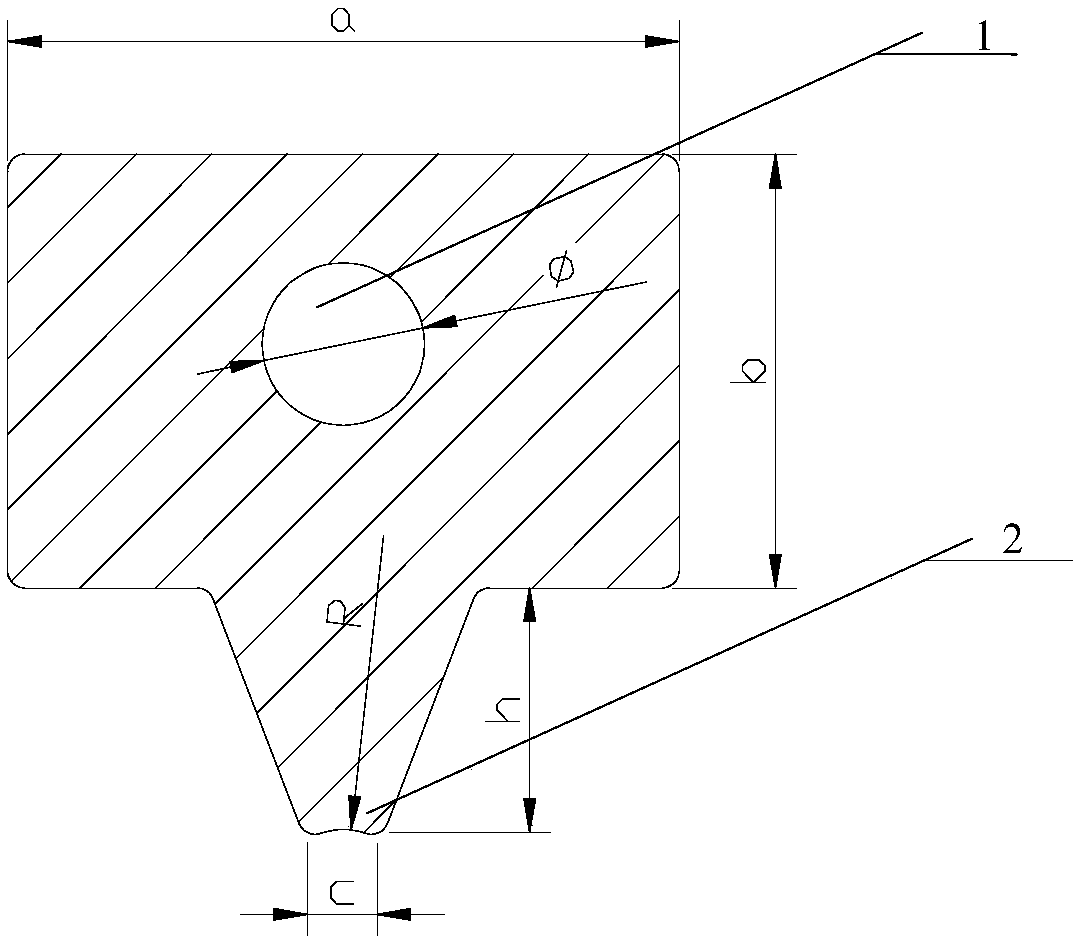

[0018] ① For the standing seam butt joint of materials with strict requirements on heat input in the storage tank project, the wall thickness range of research is selected to be ≥ 6mm. The welding process method adopts solid welding wire, 80% Ar+20% CO2 / 98% Ar+2% O2 gas front protection, and water-cooled copper backing protection.

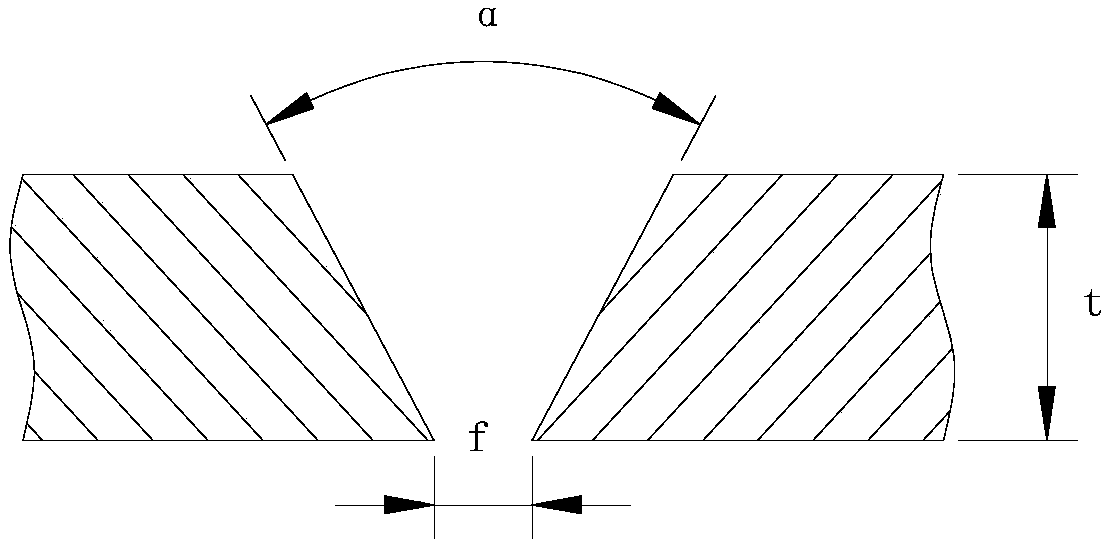

[0019] ②According to the wall thickness, make a groove, and open a V-shaped groove for the vertical welded plate of the storage tank with a wall thickness of 6-12mm (such as figure 1 ), leave gaps, no blunt edges, control the amount of misalignment, single-sided welding and double-sided molding, no root cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com