Oil return control system and control method of a gearbox flushing device

A technology of flushing device and oil return control, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as affecting the life of oil pump motor, achieve excellent working performance, simple principle, and prevent failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

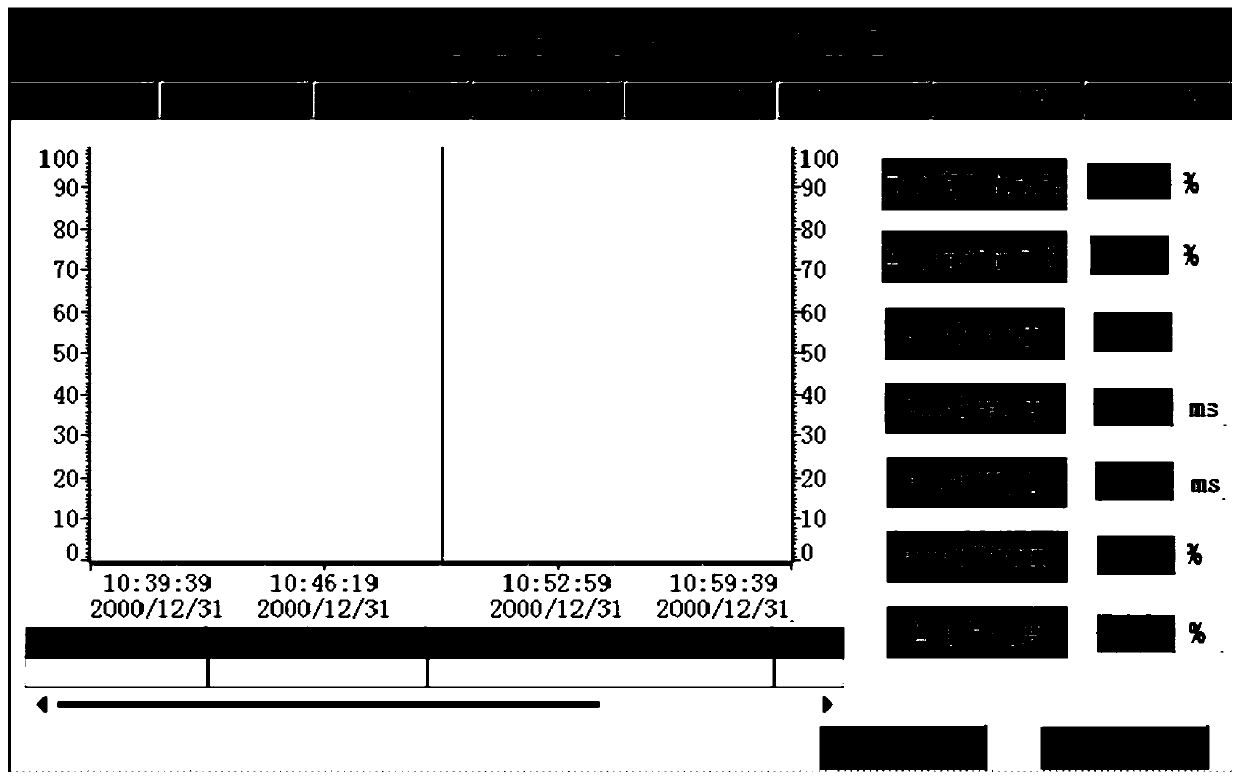

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0037] An oil return control system of a gearbox flushing device, including a flushing device and a control system, the flushing device includes a main oil tank, a flushing test bench, a gravity oil tank, and an oil return system; the control system includes a PLC, a power frequency control circuit, a frequency conversion control Loop and touch screen;

[0038] The main oil tank is used to store all the oil for system operation, the flushing test bench is used to flush the gearbox, and the gravity oil tank is used to collect the return oil of the test bench;

[0039] The oil return system includes an oil return pump connected to a power frequency motor and an oil return pump connected to a variable frequency motor. The oil return pump inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com