Agitator capable of lifting and dropping operating handle

A technology for operating handles and stirrers, which is applied to chemical instruments and methods, dissolution, mixers, etc., can solve problems such as inconvenient operation and low use efficiency, and achieve the effect of convenient operation, high use efficiency and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

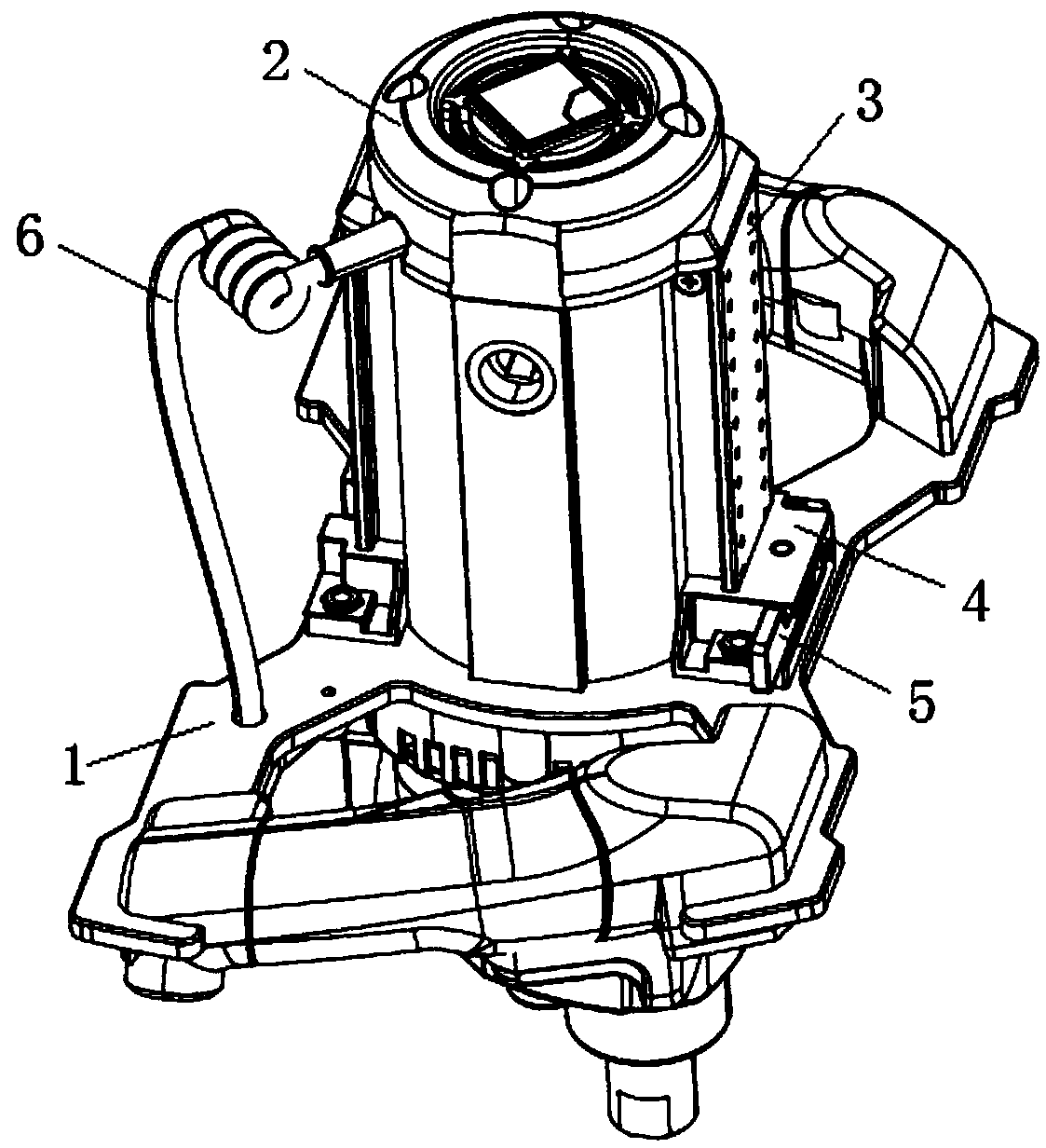

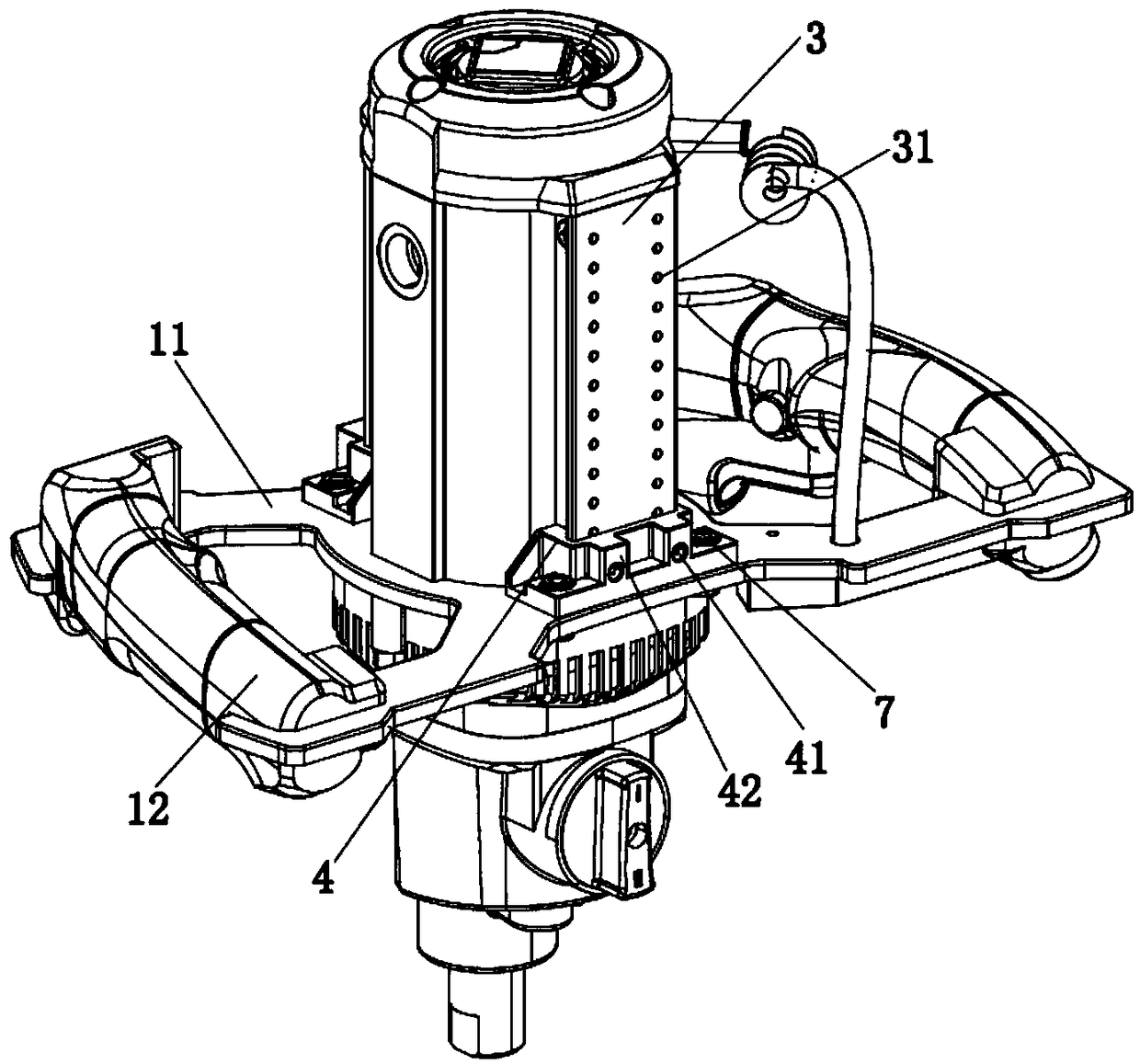

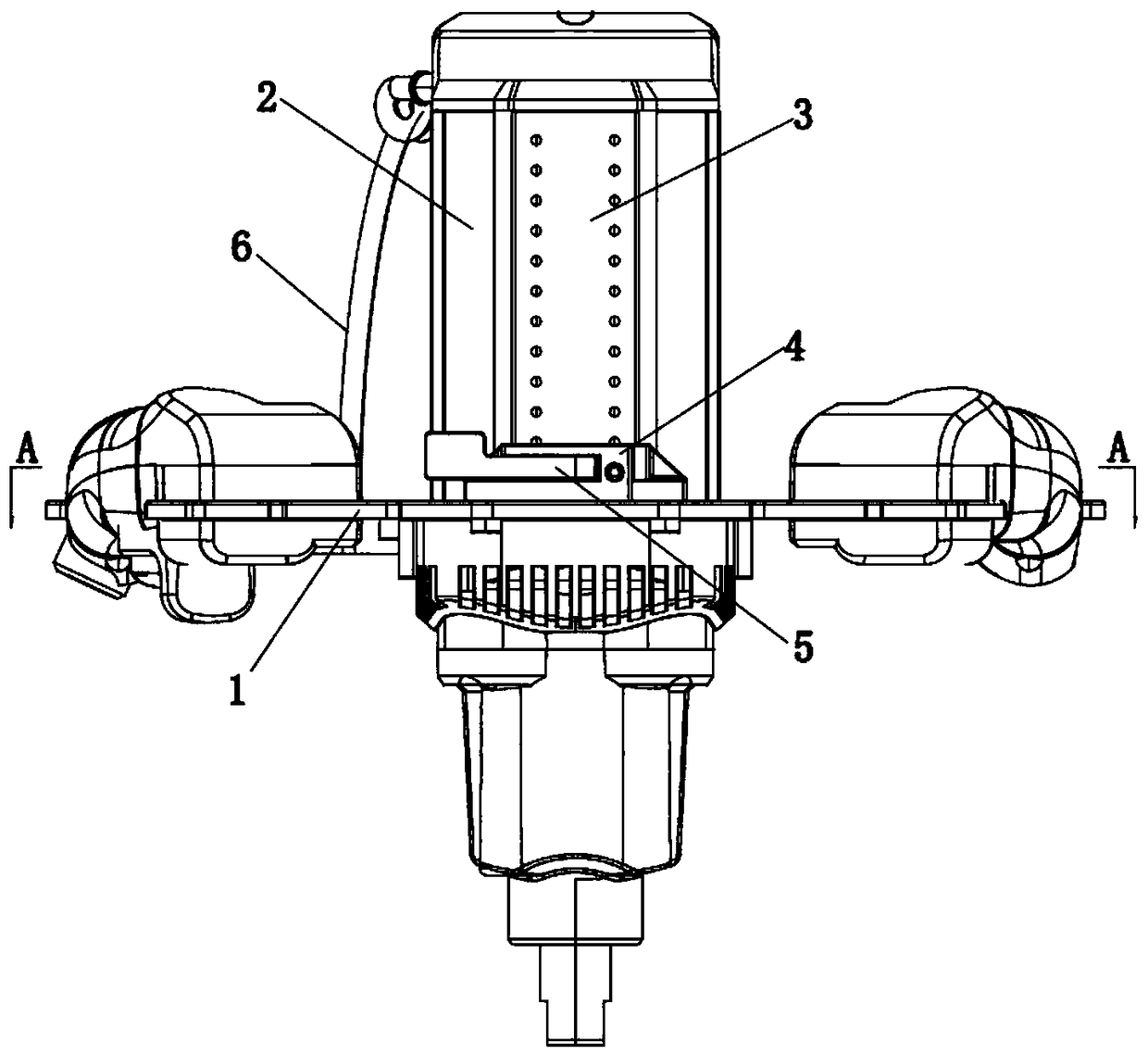

[0034] A stirrer with a liftable operating handle, comprising an operating handle 1 and a body 2 for providing rotational power, the operating handle 1 and the body 2 are socketed and matched, and a device for The power cord 6 that transmits the control signal is a spring power cord, and the power cord 6 can expand and contract by itself during the sliding adjustment process without affecting the transmission of electrical signals.

[0035] The operating handle 1 includes a frame-type mounting plate 11 and a handle 12 , the body 2 is arranged through the center of the frame of the mounting plate 11 , and the handle 12 is fixed at both ends of the mounting plate 11 . Two slide rails 3 are arranged on the side of the fuselage 2, and the two slide rails 3 are relatively distributed on both sides of the fuselage 2, and a slide block 4 adapted to the slide rail 3 is respectively arranged on both sides of the mounting plate 11, and the slide block 4 is provided with a locking mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com