Wheat germ processing method

A technology of wheat germ and processing method, which is applied in food science and other fields, can solve the problems of high enzyme activity, easy oxidative rancidity, poor instant palatability of wheat germ, etc., and achieve the effect of uniform temperature and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 (a kind of processing method of wheat germ)

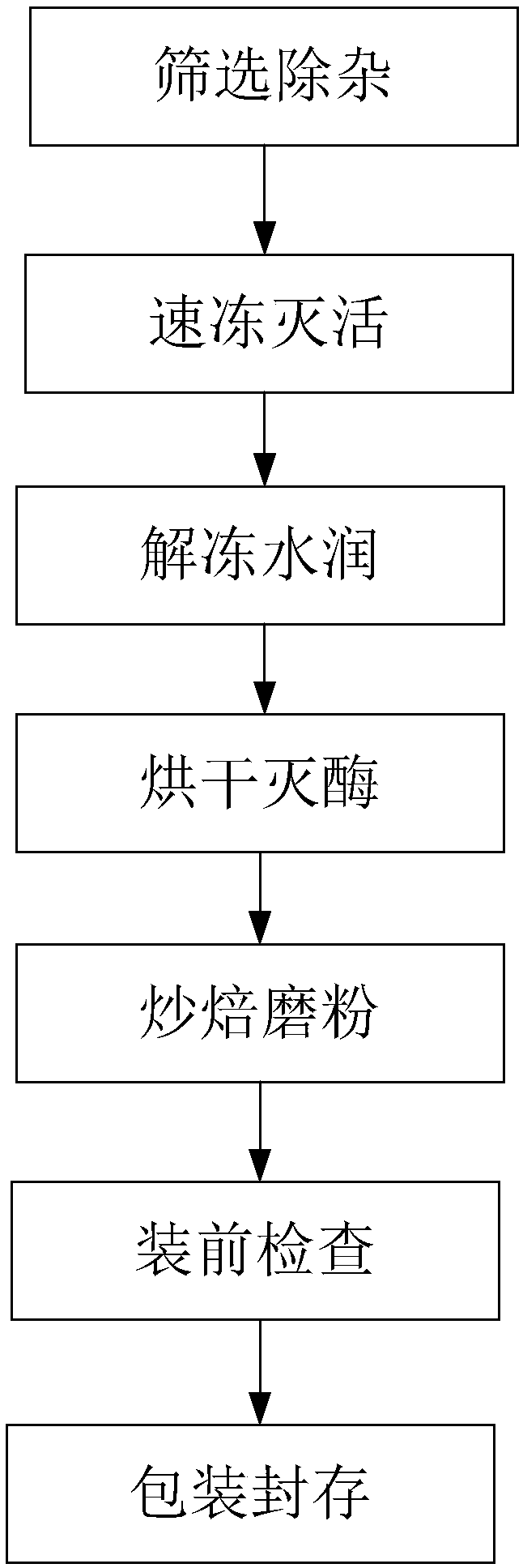

[0026] like figure 1 As shown, the present invention provides a kind of processing method of wheat germ, at first fresh wheat germ is carefully selected, then utilizes suction separator to separate impurities such as bran, dust mixed in wheat germ; Select the qualified wheat germ after impurity removal for quick-freezing and inactivation. Within the temperature range of -30°C to -18°C, the wheat germ is quick-frozen within 20 minutes, so that the wheat germ forms extremely small ice crystals and does not seriously damage the cell tissue , low-temperature inactivation, thereby preserving the original aroma and nutritional components of wheat germ, and prolonging the storage time; but when wheat germ is needed, remove the quick-frozen wheat germ to thaw it out of the frozen state, and then perform moisturizing treatment to soak it evenly In the water, the moisture in the wheat germ is readjusted to improve its ph...

Embodiment 2

[0028] Select fresh wheat germ, and then use the suction separator to separate the impurities such as bran and dust mixed in the wheat germ; then perform quick freezing and inactivation on the qualified wheat germ after selection and removal, and use The wheat germ is quick-frozen within 10 minutes, so that the wheat germ forms extremely small ice crystals, does not seriously damage the cell tissue, and is inactivated at low temperature, thereby preserving the original aroma and nutritional components of the wheat germ and prolonging the storage time; but it needs When wheat germ is used, the quick-frozen wheat germ is removed from the frozen state, and then hydrated, soaked in water evenly, so that the moisture in the wheat germ can be readjusted, and its physical, biochemical and milling process performance can be improved; The hydration-treated wheat germ is not much different from the fresh wheat germ, and then dried to eliminate enzymes. First, the hydration-treated wheat ...

Embodiment 3

[0030] Select fresh wheat germ, and then use a suction separator to separate out impurities such as bran and dust mixed in the wheat germ; then perform quick freezing and inactivation on qualified wheat germ after selection and removal, and use The wheat germ is quick-frozen in less than 15 minutes, so that the wheat germ forms extremely small ice crystals, does not seriously damage the cell tissue, and is inactivated at low temperature, thereby preserving the original aroma and nutritional components of the wheat germ and extending the storage time; but it needs When wheat germ is used, the quick-frozen wheat germ is removed from the frozen state, and then hydrated, soaked in water evenly, so that the moisture in the wheat germ can be readjusted, and its physical, biochemical and milling process performance can be improved; The hydration-treated wheat germ is not much different from the fresh wheat germ, and then dried to eliminate enzymes. First, the hydration-treated wheat g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com