Wide-range air velocity transducer and manufacturing method thereof

A wind speed sensor, wide-range technology, applied in the direction of using thermal variables to measure fluid speed, instruments, measuring devices, etc., can solve the problems of small measurement range, limited popularization and application, high cost, easy batch production, reliable process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

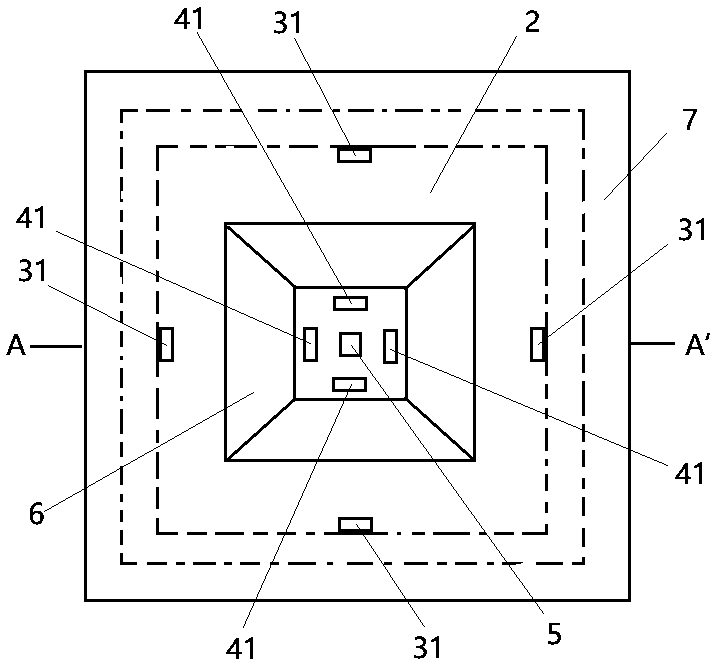

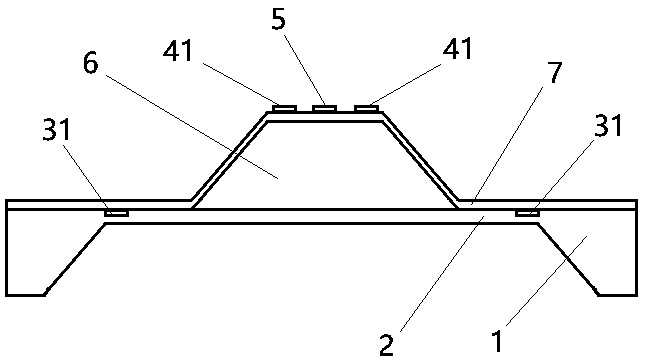

[0029] Such as figure 1 and figure 2 As shown, the present invention designs a wide-range wind speed sensor. In practical application, it specifically includes a substrate 1, an elastic film 2, a heating element 5, a raised table top 6, a heat insulation layer 7, four pressure sensors 31 and four temperature sensor 41.

[0030] Wherein, the material of the substrate 1 and the material of the elastic film 2 are identical to each other, and the center position of the substrate 1 is provided with a through hole running through its upper and lower surfaces, and the shape and size of the elastic film 2 are the same as the shape and size of the through hole on the substrate 1. Correspondingly, the elastic film 2 is arranged in the through hole of the substrate 1, and the edge of the elastic film 2 abuts the inner edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com