Automatic and on-line method for weighing and measuring thickness of plate glass

An automatic weighing and flat glass technology, applied in weighing, measuring devices, instruments, etc., can solve the problems affecting the yield rate and production efficiency of the production line, low detection frequency, multi-manpower and other problems, so as to improve the detection efficiency and monitoring strength, High stability and reliability, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

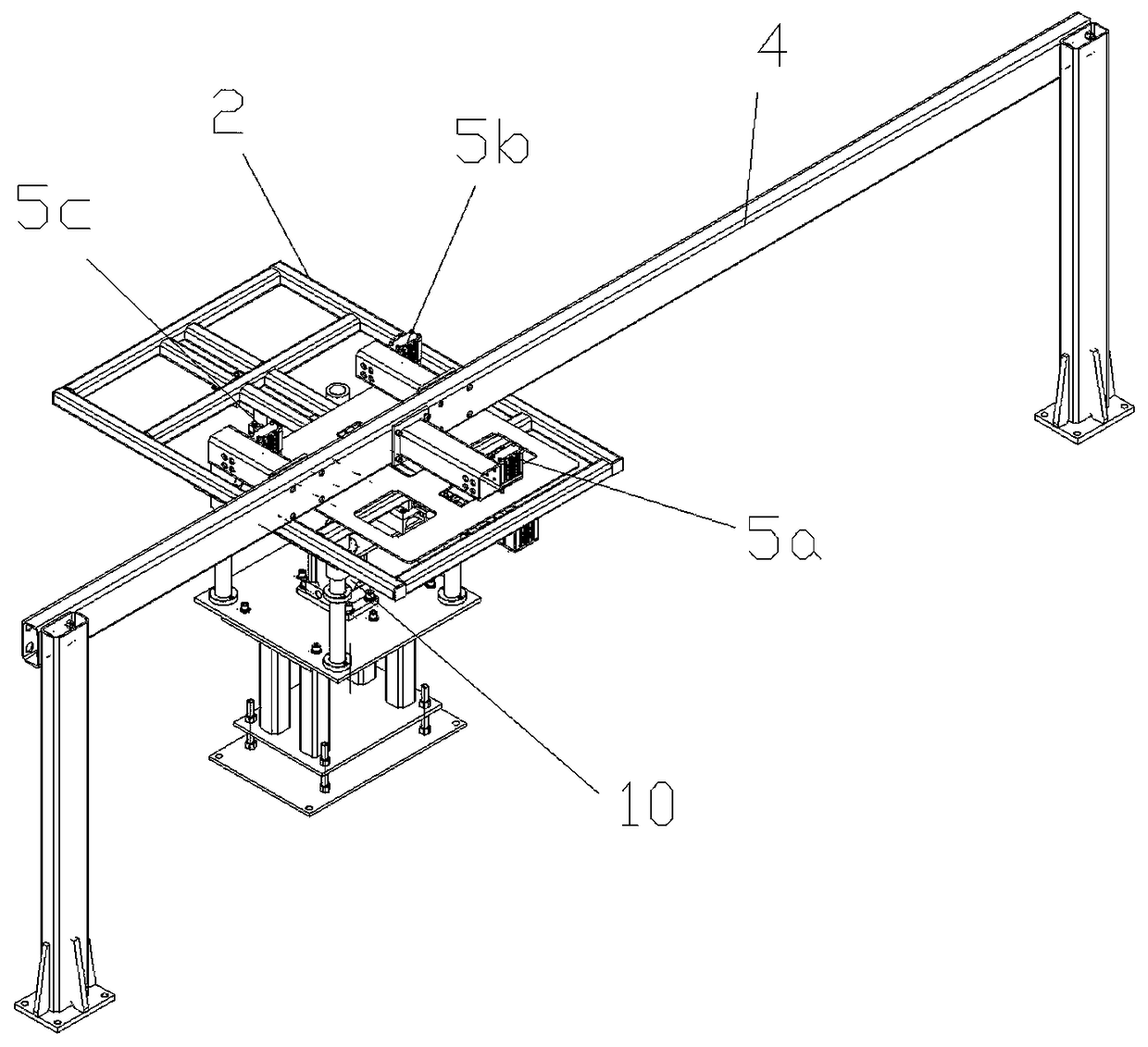

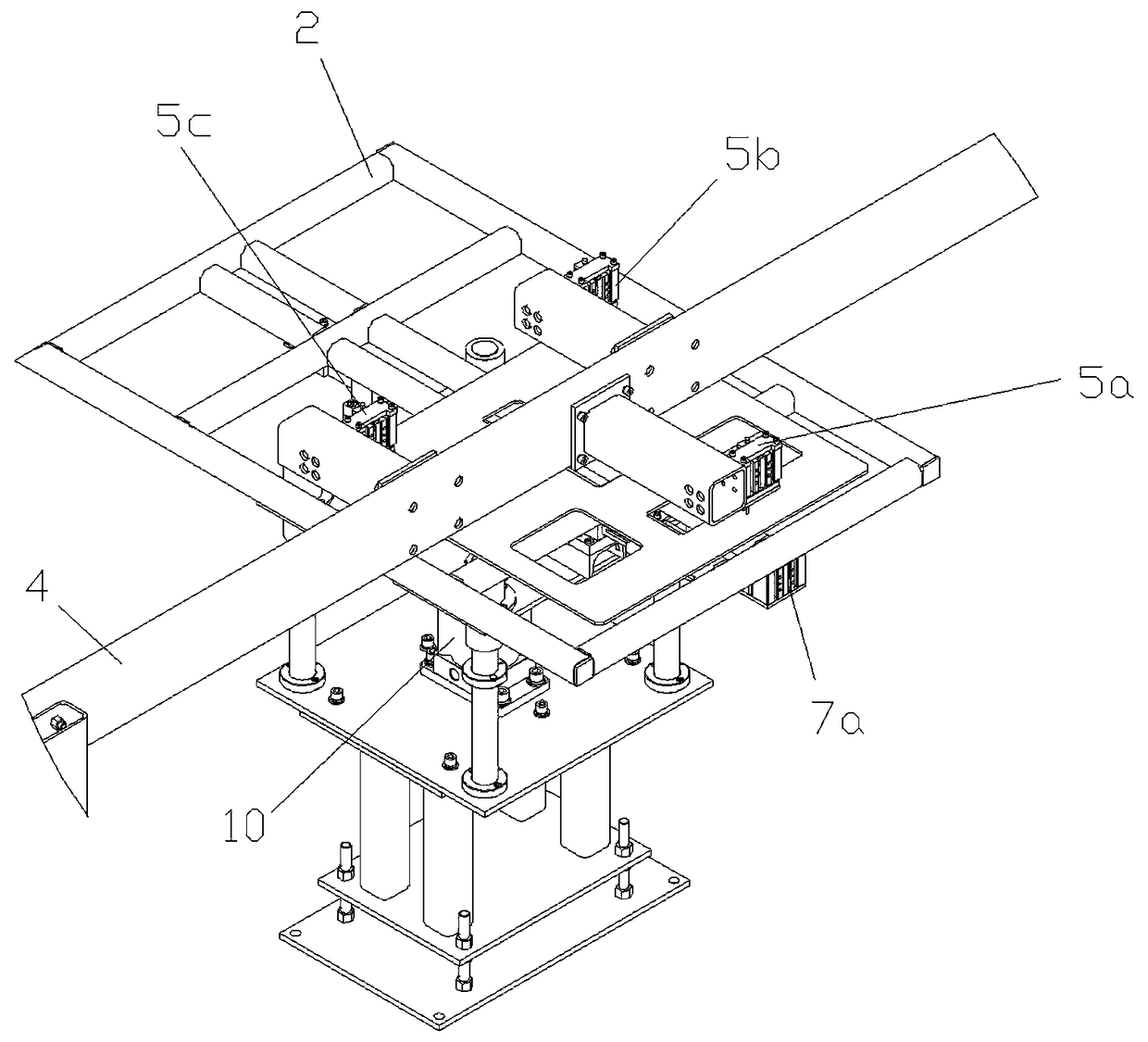

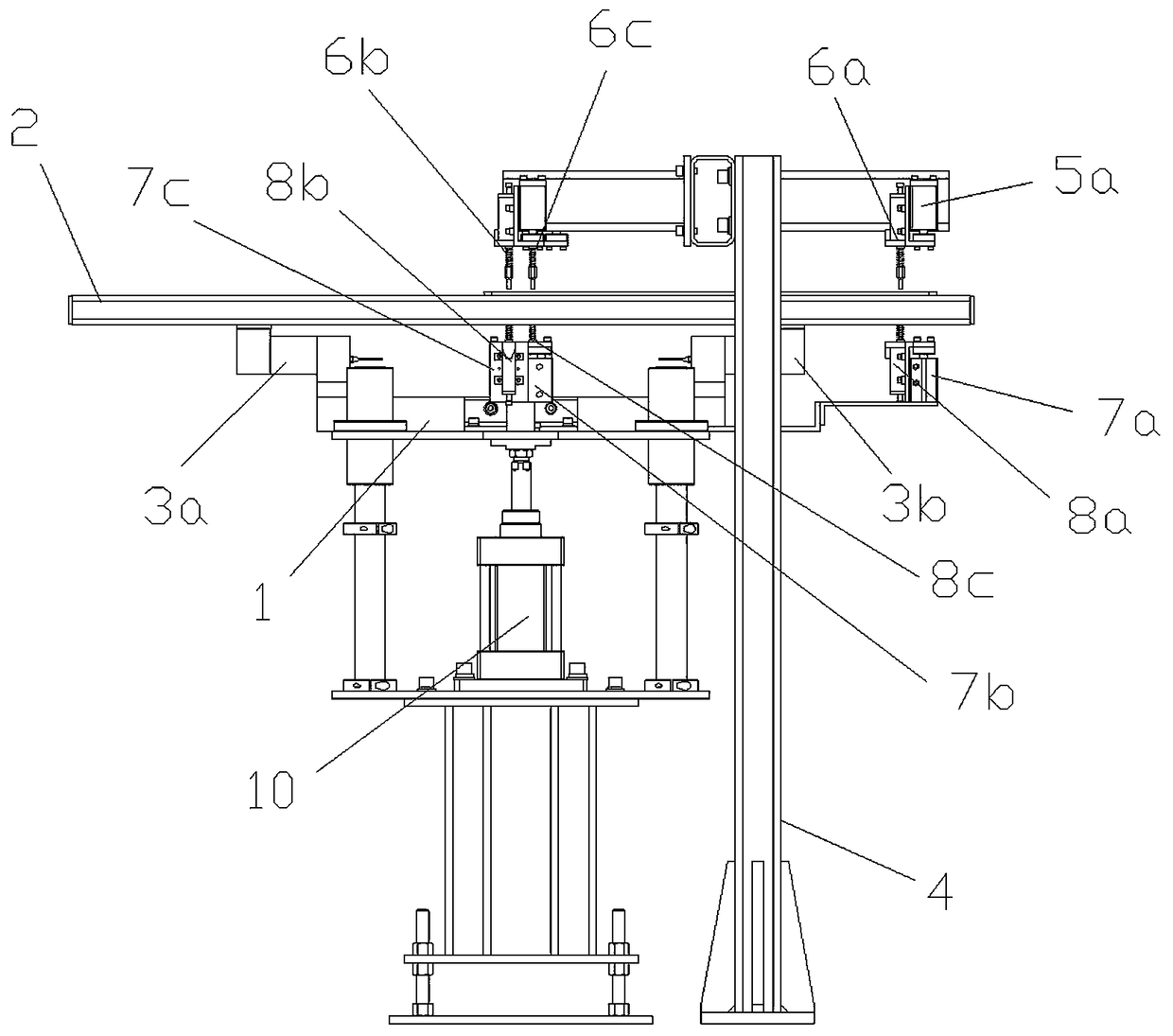

[0024] combine Figure 1~3 As shown, the present invention provides a method for online automatic weighing and thickness measurement of flat glass, comprising the following steps:

[0025] a. A parallel beam load cell is set between the support frame 1 of the glass slicing table and the slicing platform 2 of the glass slicing table. The parallel beam load cell includes two, and the first parallel beam load cell 3a is parallel to the second The beam load cell 3b is respectively arranged at the two ends of the support frame of the glass slicing table;

[0026] The gantry 4 across the glass slicing table is set, and three upper measuring cylinders are vertically arranged on the gantry 4, namely the first upper measuring cylinder 5a, the second upper measuring cylinder 5b and the third upper measuring cylinder 5c; The measuring cylinders are in a triangular distribution, and each upper measuring cylinder is connected to the upper displacement sensor respectively, that is, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com