Rolling device

A rolling and equipment technology, used in mechanical equipment, material gluing, connecting components, etc., can solve the problem that the back cover and the back of the mobile phone are not fully fitted, the side curved surface is not easy to be pressed, and the strength of the pressing cannot be controlled. and other problems, to achieve the effect of reducing manual operation time, reducing labor intensity of workers, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

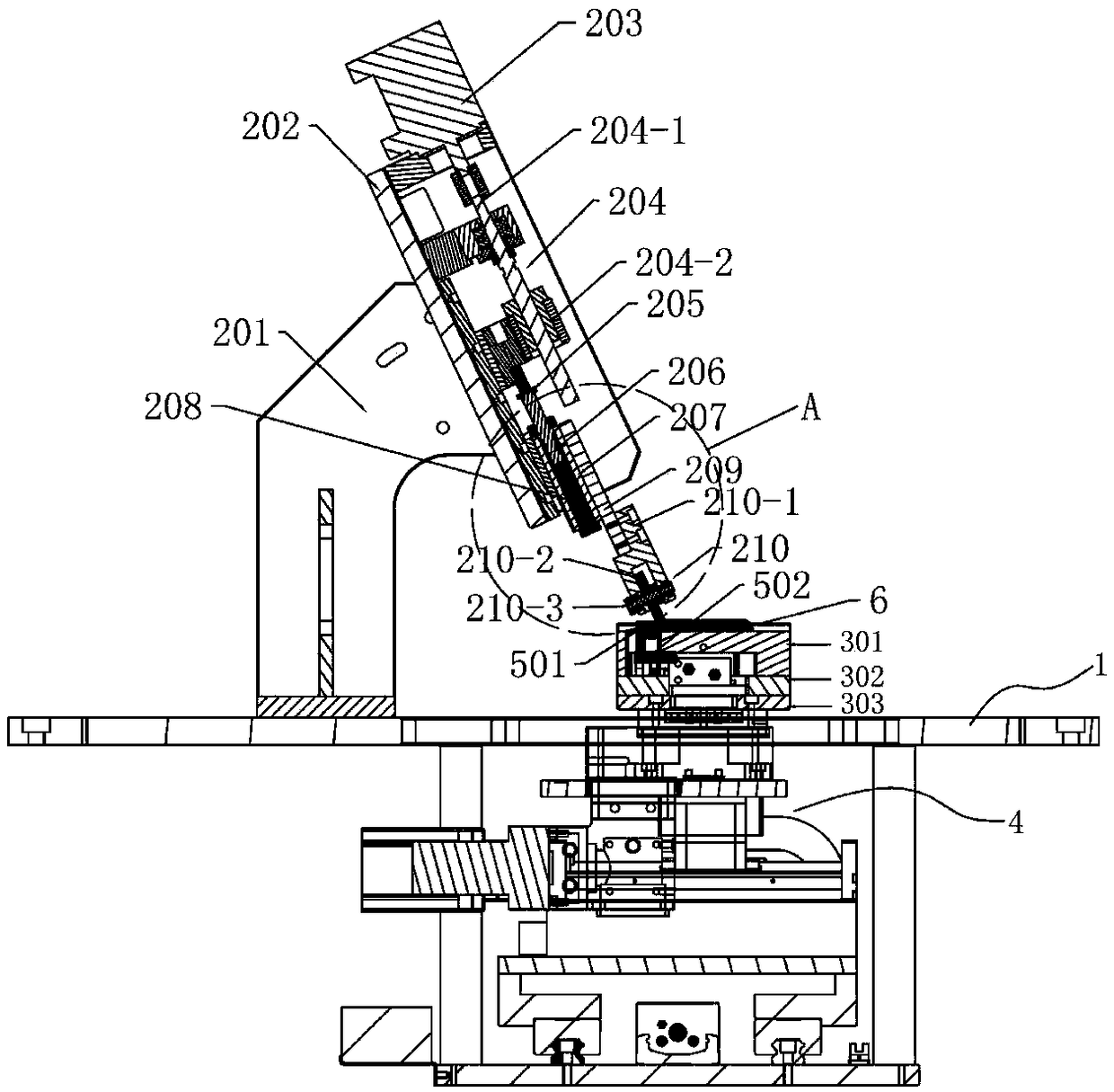

[0019] Implementation 1: see Figure 1 to Figure 4 , in an embodiment of the present invention, a rolling equipment includes a man-machine control system, a base 1, a rolling mechanism 2, a stage 3 and a stage driving device 4, and a mounting hole 101 is provided in the middle of the base 1, The stage 3 is in the mounting hole 101 of the base 1, the rolling mechanism 2 is fixed above the stage 3 and on one side of the mounting hole 101, and the rolling mechanism 2 is inclined It is arranged above the carrier 3 ; the carrier driving device 4 is below the carrier 3 and connected to the carrier 3 by driving.

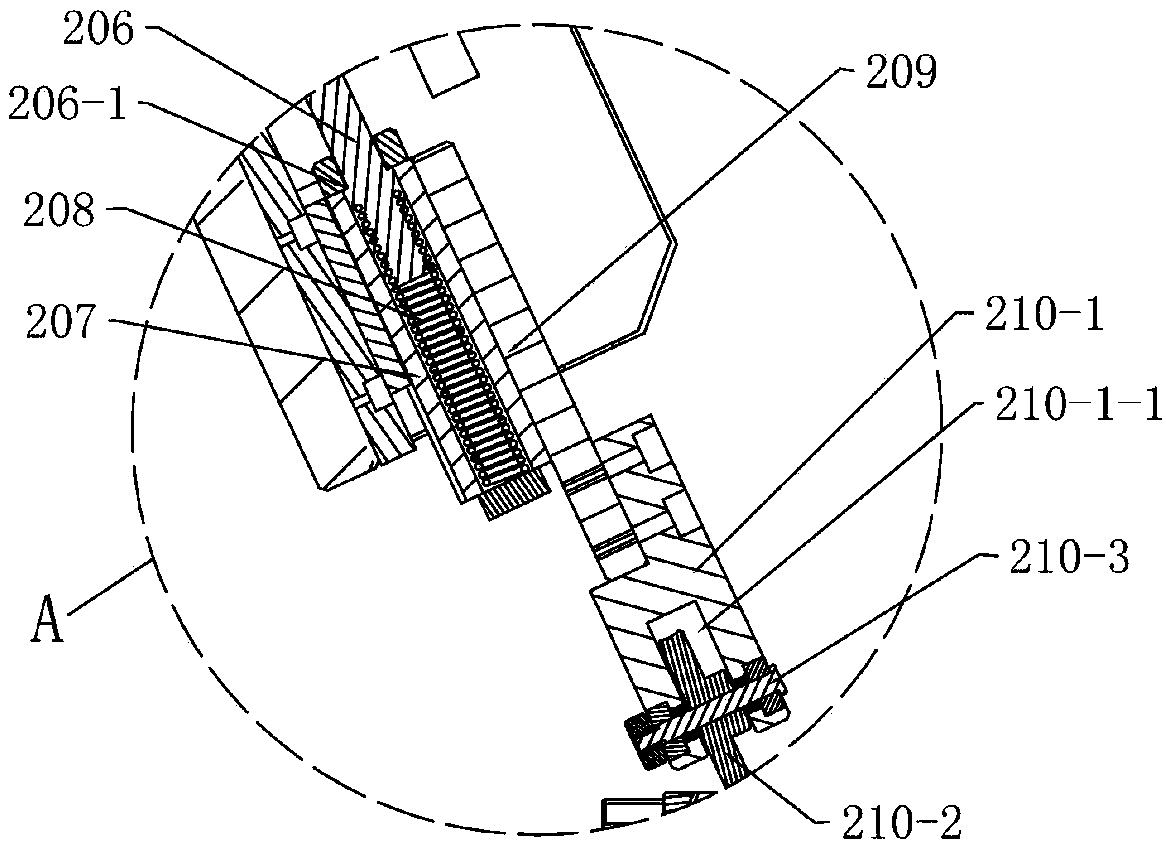

[0020] The rolling mechanism 2 includes a fixed seat 201, a rolling shell 202, a rolling drive motor 203, a screw assembly 204, a pull rod 206, a pulling block 207 and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com