Reinforcing structure at sunlight room aluminum profile joint with reinforcing plate and sunlight room installation method using same

A technology for strengthening structures and aluminum profiles, applied in building construction, building maintenance, construction, etc., can solve the problems of limited bearing strength, inability to achieve large spans, and looseness of aluminum alloy sunrooms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

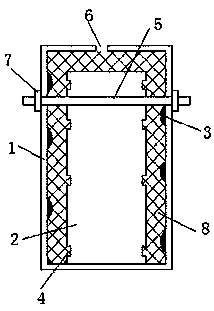

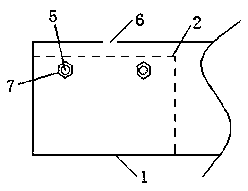

[0031] A reinforced structure for the connection of aluminum profiles in a sun room with a reinforcement plate, which is set by welding two aluminum profiles 1 at a certain angle as an example. The inner cavity is respectively provided with a reinforcing plate 2 connecting the aluminum profiles 1 on both sides through positioning bolts 5, where the end of the aluminum profile refers to the length extending at least 30 cm from one end of the aluminum profile to the midpoint of the aluminum profile. The middle part of the positioning bolt 5 passes through the reinforcing plate 2 and the two ends respectively pass through the aluminum profile 1 and the two ends are respectively provided with locking nuts 7 . Specifically, it refers to: positioning holes are set on the opposite sides of the aluminum profile 1, corresponding con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com