Construction method of fabricated high slope anchor rod sash beam formworks

A construction method and assembly technology, which can be used in excavation, sheet pile wall, foundation structure engineering and other directions, can solve problems such as waste of concrete, and achieve the effects of remarkable economic benefits, beautiful lines, and convenient hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

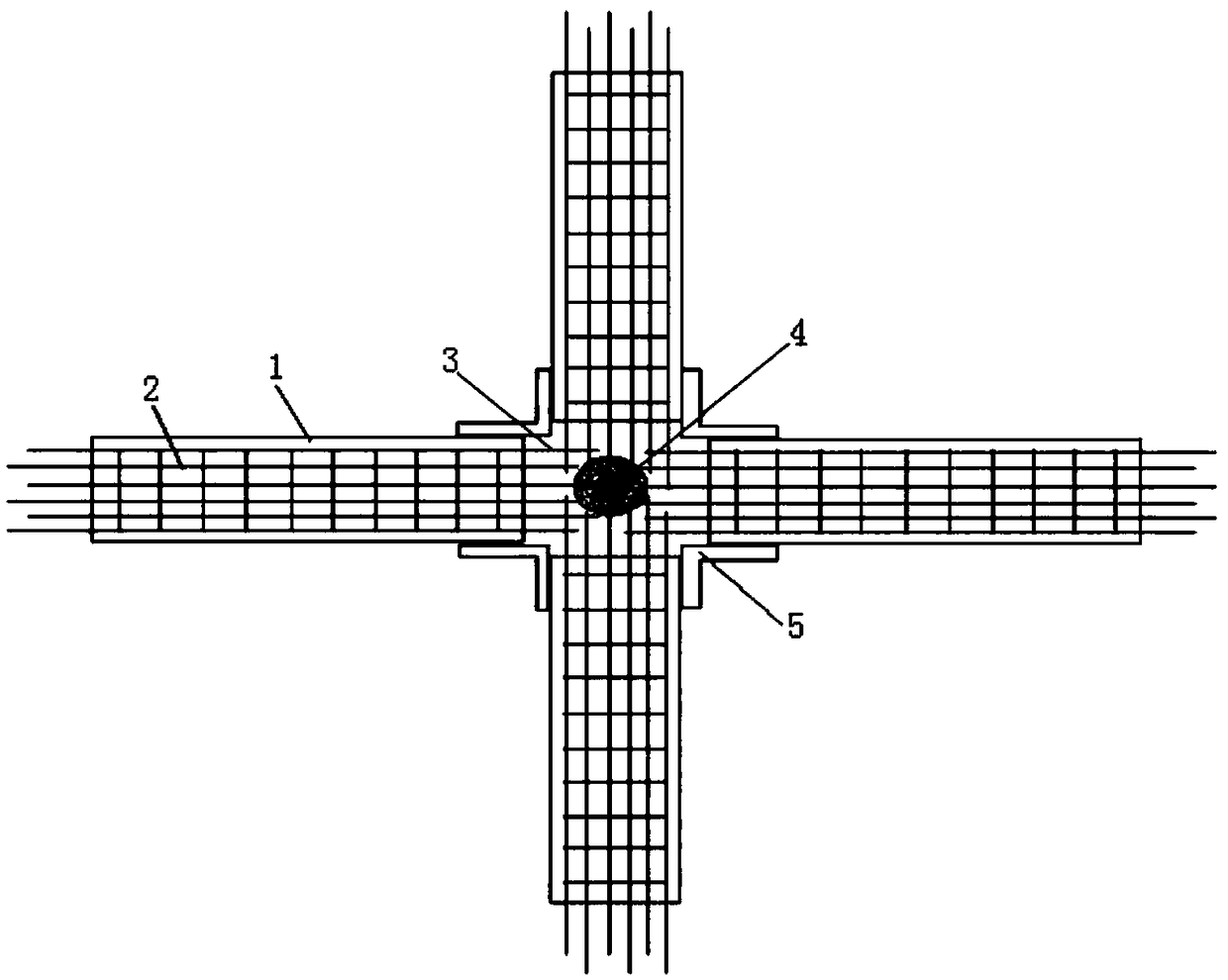

[0031] from Figure 1-5 It can be seen that the construction method of a prefabricated anchor bar frame beam formwork for high slopes in this embodiment has the following steps:

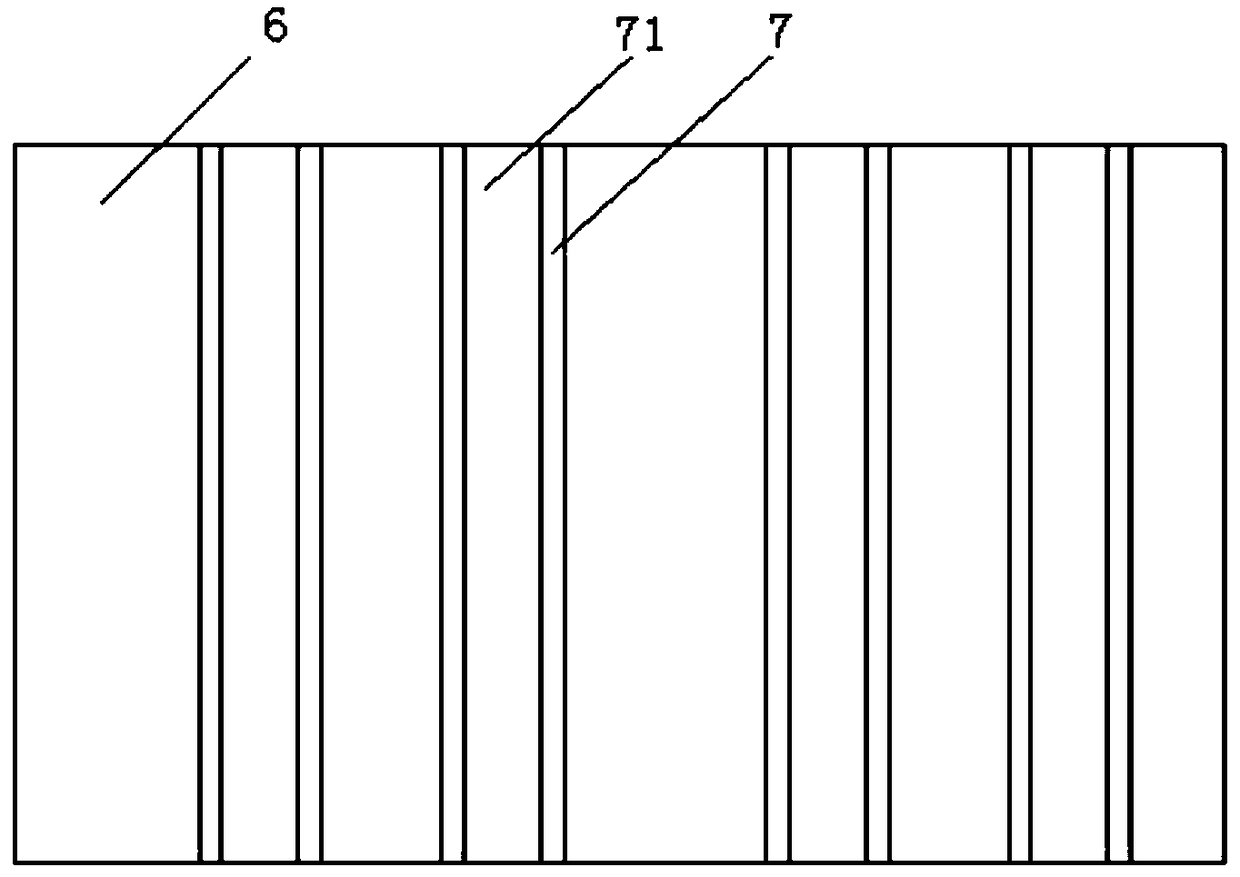

[0032] Step 1: planning the concrete site 6, and pouring C25 concrete on the concrete site 6;

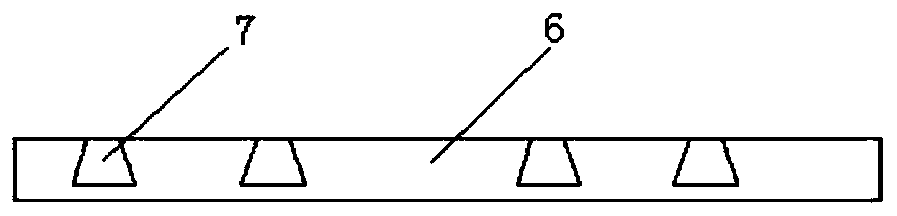

[0033] Step 2: Install the slide rail 7 and the base rigid mold 71 during the pouring process, and the slide rail 7 and the base rigid mold 71 are closely attached;

[0034] Step 3: Assemble the frame beam body 1, the outer side of the frame beam body 1 is bound with a steel skeleton 2, the two ends of the frame beam body 1 are reserved with connecting steel bars 3, and the frame beam bodies 1 are fixed by lap welding of the connecting steel bars 3 Anchor rods 4 are applied between adjacent frame beams 1, and the outer side of the frame beams 1 is fixed with a concrete formwork 5 at the connecting part, and the distance between the slide rails 7 is consistent with the width of the frame beams 1;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com