Multi-effect combined mud-water separation system

A mud-water separation and mixed liquid technology, which is applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of large area occupied by sedimentation tanks and reduce the area occupied , Good effluent quality and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

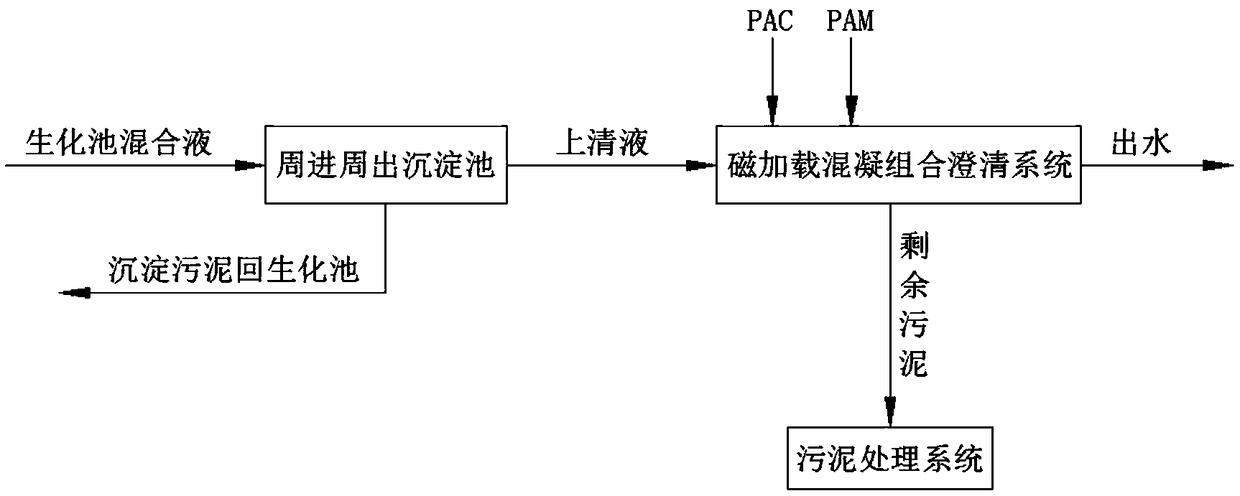

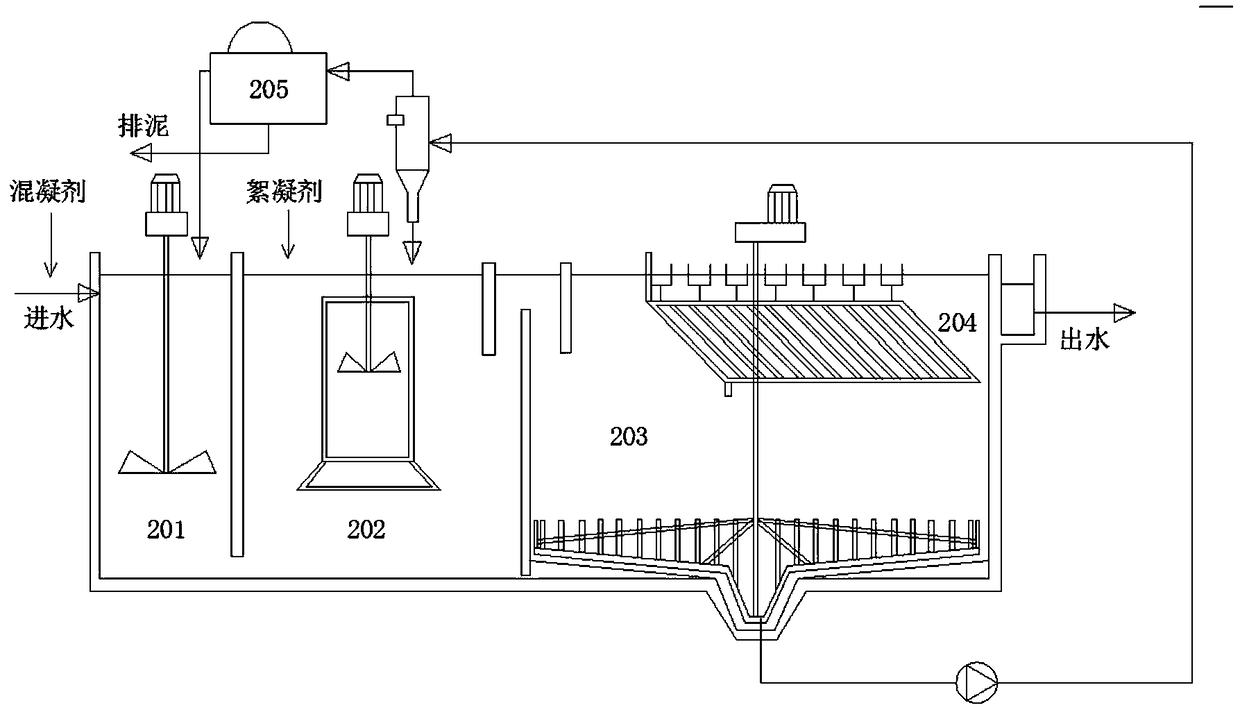

[0036] In the optional scheme of this embodiment, such as figure 1 , figure 2 As shown, a multi-effect combined mud-water separation system provided in this embodiment includes a settling tank 100 in and out of the circle and a magnetically loaded coagulation combined clarification system 200;

[0037] The week-in and week-out sedimentation tank 100 is connected to the magnetic loading coagulation combined clarification system 200 through pipelines;

[0038] The sedimentation tank 100, which enters and exits the week, is a peripheral water inlet and peripheral water outlet auxiliary flow sedimentation tank, which is used for the pre-sedimentation and separation of sludge and water from the sludge mixture, and can separate the mud and water from the mixture of biochemical tanks. The shape of the sedimentation tank is circular;

[0039] The supernatant discharged from the sedimentation tank 100 in and out of the week enters the subsequent magnetic loading coagulation combined ...

Embodiment 2

[0067] In an alternative solution of this embodiment, different from Embodiment 1, the sedimentation tank has a rectangular shape.

Embodiment 3

[0069] In the optional scheme of this embodiment, different from Embodiment 1 or Embodiment 2, the design surface hydraulic load value of the sedimentation tank 100 entering and exiting the circle is 3m 3 / m 2 / h, the area occupied by the sedimentation tank 100 entering and exiting the week and the area occupied by the magnetic loading coagulation combined clarification system 200 are also reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com