One-stop integrated process for making wallboards on site by using construction waste as raw materials and wallboard

A technology of construction waste and on-site production, which is applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of high transportation costs, adverse environmental effects, and reduce production costs, so as to improve the conversion rate of waste utilization and reduce cleaning Transportation link, the effect of avoiding damage and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

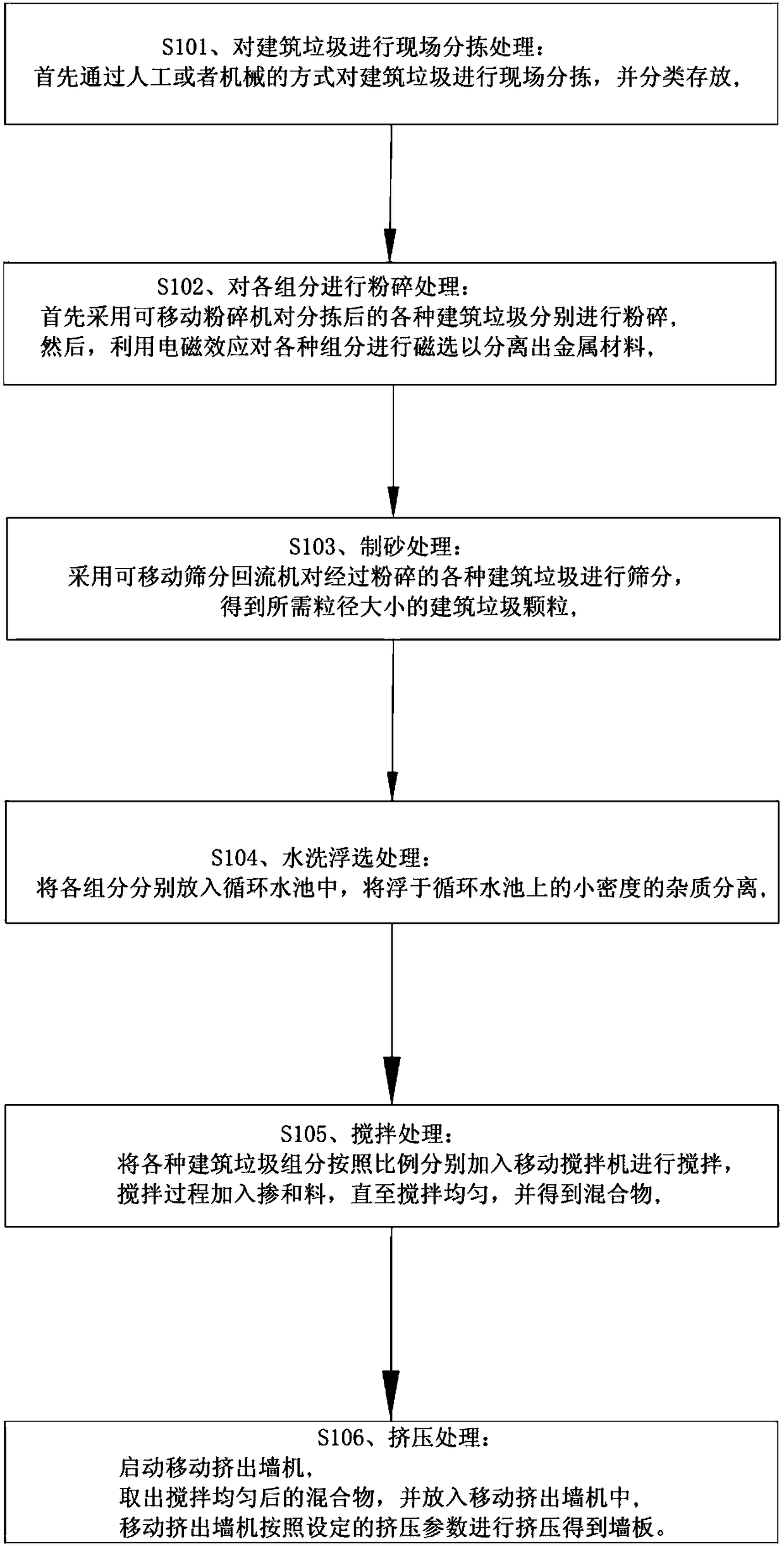

[0043] Below will combine the appended in the embodiment of the present invention figure 1 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0044] The preparation method of the invention is suitable for the extrusion molding production of wallboards using construction waste as raw materials. It should be noted that, unlike the traditional preparation of building boards from construction waste, in this embodiment, all the equipment used is placed on the site of construction waste, and each process can be completed on the site of construction waste, without the need for specific processing sites and raw materials. Long-distance transportation; can greatly improve production efficiency, save resources and reduce costs.

[0045] Specifically, this one-stop integrated process for on-site production of wall panels u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com