A volatile organic waste gas adsorbent having humidity stability and consisting of an MOFs/CNTs composite material

A volatile organic and composite material technology, used in gas treatment, air quality improvement, membrane technology, etc., can solve the problems of powdery and low mechanical strength of MOFs, and achieve the effect of high humidity stability and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

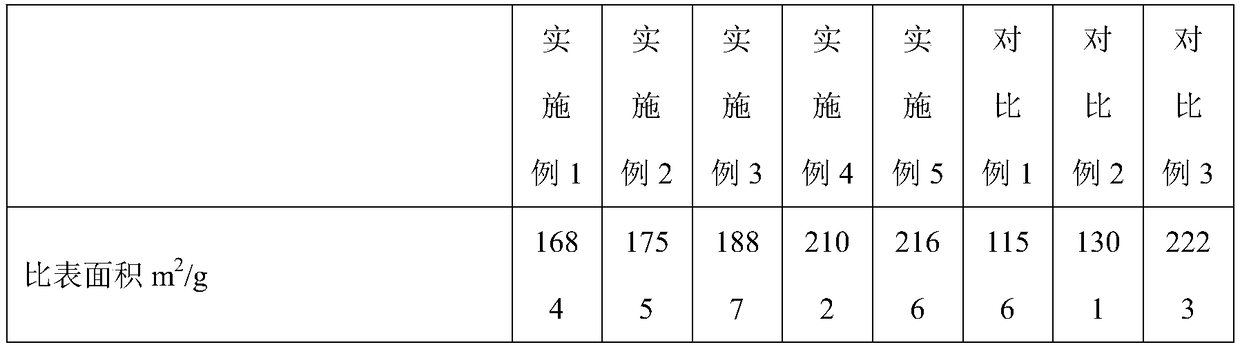

Embodiment 1

[0038] Preparation of volatile organic waste gas adsorbent using MOF-74 / CNTs composite material:

[0039] Weigh Co(NO 3 ) 2 ·6H 2O (750mg) and 2,5-dihydroxyterephthalic acid DOBDC (250mg) were dissolved in 100mL DMF-ethanol-water mixed solvent with a volume ratio of 1:1:1 in a 250mL reaction bottle, and a certain amount of poly Walled carbon nanotubes were subjected to ultrasonic treatment for 20 minutes and then placed in an oven at 100°C for 24 hours of reaction. Take it out from the oven and cool it to near room temperature, pour out the reaction mother liquor, and obtain a brown-red crystal material. After the crystals were washed 3 times with DMF (3×20 mL), the solvent was replaced with methanol for 3d (3×3×20 mL). The Co-MOF-74 material after methanol replacement was desolvated in vacuum at room temperature for 6 h, and then slowly heated to 250 °C for 12 h under vacuum. A composite material of MOF-74 / CNTs is obtained, wherein the mass fraction of carbon nanotubes i...

Embodiment 2

[0041] The difference between this example and Example 1 is that the mass fraction of carbon nanotubes in the MOF-74 / CNTs composite material is 1%, and the amount of other raw materials used and the operation steps are the same as in Example 1.

Embodiment 3

[0043] The difference between this example and Example 1 is that the mass fraction of carbon nanotubes in the MOF-74 / CNTs composite material is 3%, and the amount of other raw materials used and the operation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com