Color-film substrate and manufacturing method thereof

A color filter substrate and manufacturing method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of weakening light intensity, overall brightness of the display screen, and excessive power consumption of products, so as to enhance the display brightness and solve the problem of display Insufficient brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

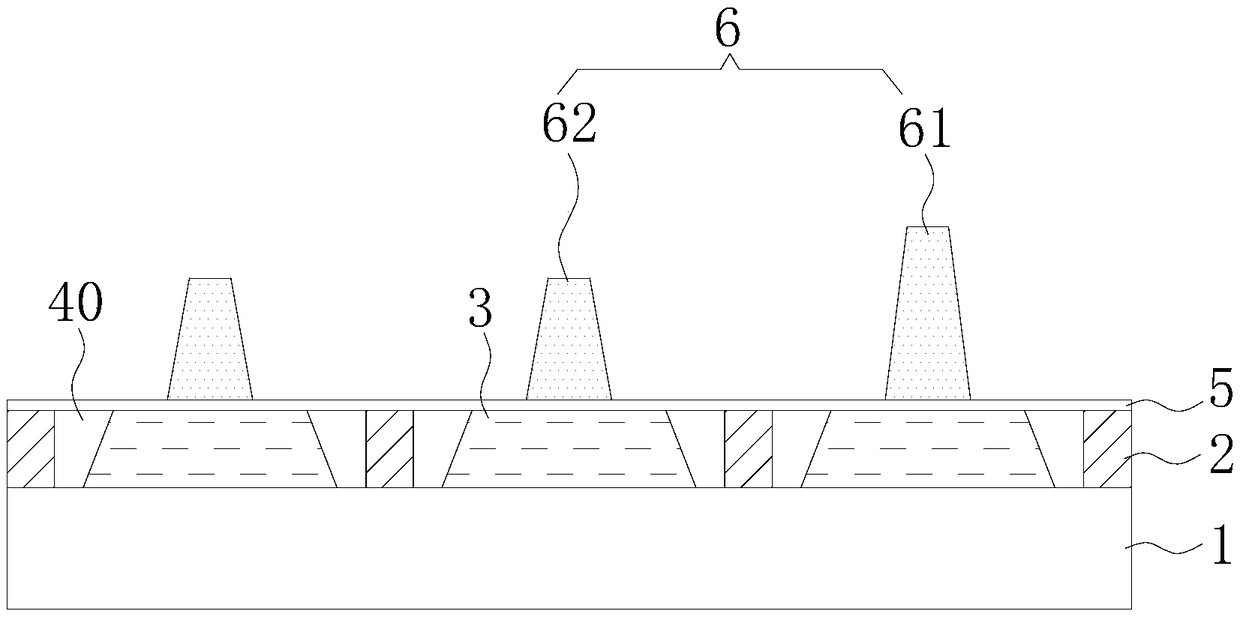

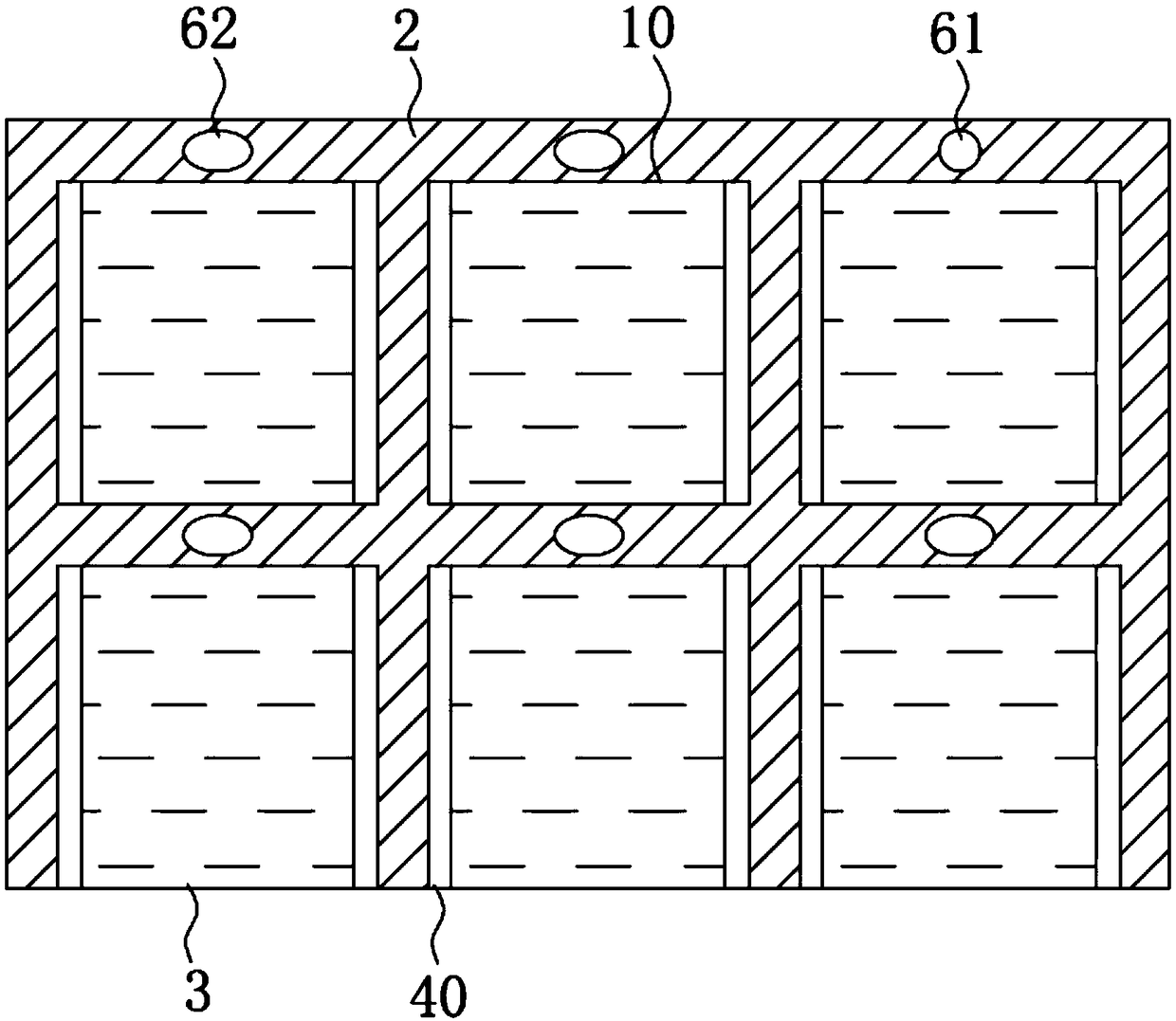

[0026] refer to figure 1 and figure 2 As shown, this embodiment provides a color filter substrate, including a transparent substrate 1 , a black matrix 2 and a plurality of color resist blocks 3 .

[0027] Wherein, the black matrix 2 is arranged on the transparent substrate 1 to form a plurality of pixel areas 10, the color resistance block 3 is arranged in the corresponding pixel area 10, the color resistance block 3 and the black matrix 2 There are spacer grooves 40 between them.

[0028] In the color filter substrate, when each of the color-resisting blocks 3 is arranged in the corresponding pixel area 10, the interval groove 40 is provided between the color-resisting block 3 and the black matrix 2, so that the A spaced area is formed between the color resist block 3 and the black matrix 2 , and the light irradiated to the color filter substrate can pass through the spaced groove 40 . When the color filter substrate is applied to a liquid crystal display panel, a part o...

Embodiment 2

[0036] This implementation provides a method for manufacturing a color filter substrate, combining Figure 5a-5d or Figure 6a~6d As shown, the preparation method comprises the steps of:

[0037] Such as Figure 5a Or as shown in 6a, a transparent substrate 1 is provided, and a black matrix 2 is fabricated on the transparent substrate 1, and the black matrix 2 divides the transparent substrate 1 into a plurality of pixel areas 10;

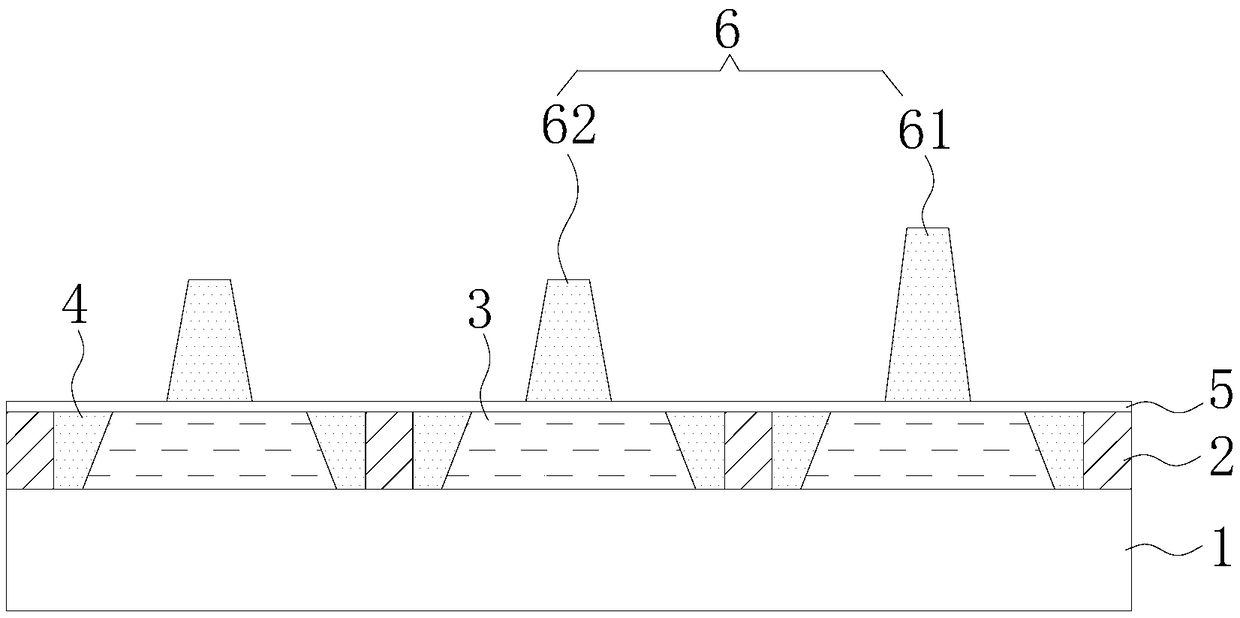

[0038] Such as Figure 5b Or as shown in 6b, a corresponding color-resist block 3 is fabricated in the pixel area 10, and there is a spacer 40 between the color-resist block 3 and the black matrix 2.

[0039]As an embodiment of the manufacturing method of the color filter substrate, as Figure 5c As shown, the manufacturing method further includes the step of: filling the spacer grooves 40 with a transparent photoresist material to form spacer photoresist blocks 4 .

[0040] Further, as Figure 5d As shown, in this embodiment, the manufacturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com