Stepped sealing structure of optical cable connector box

A technology of optical cable joint box and sealing structure, which is applied in the direction of fiber mechanical structure, light guide, optics, etc., can solve the problems of insufficient temperature cycle performance, high construction operation requirements, and poor sealing performance, so as to reduce product operation risks, The product has a wide range of adaptability and the effect of increasing the sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

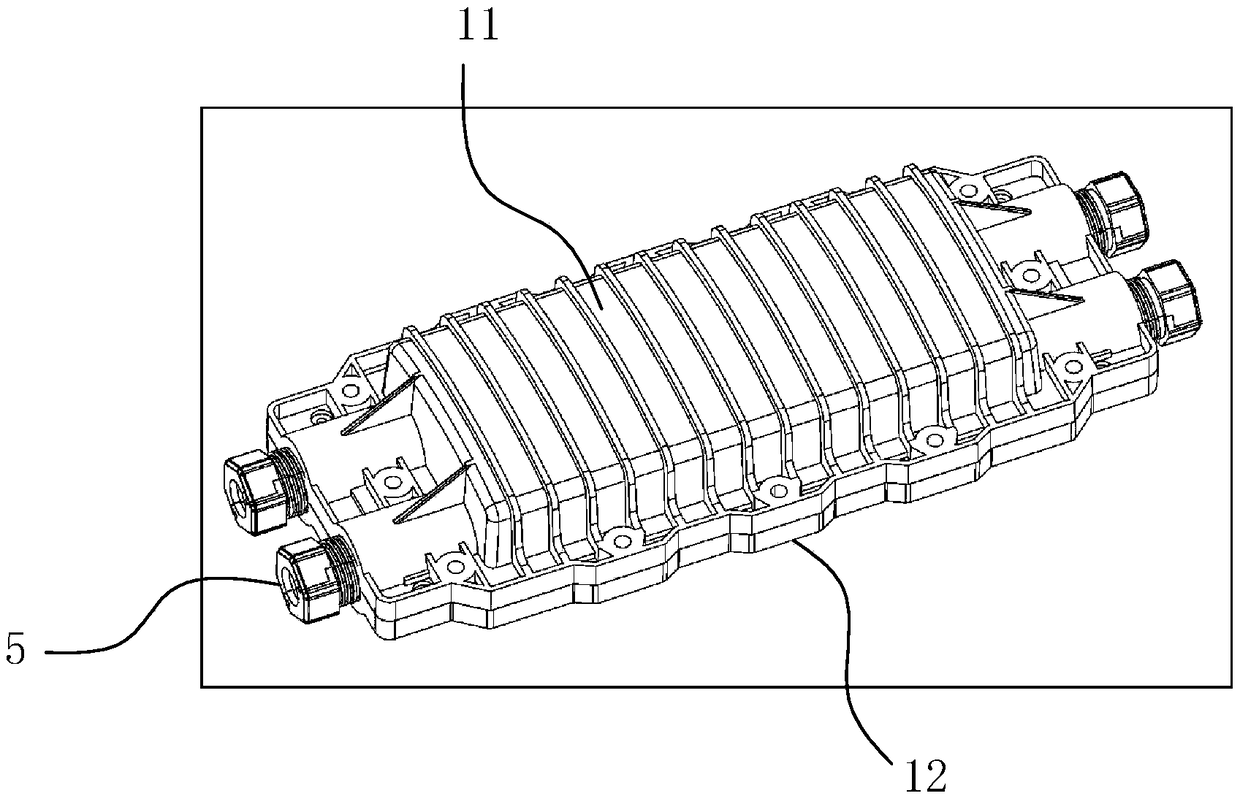

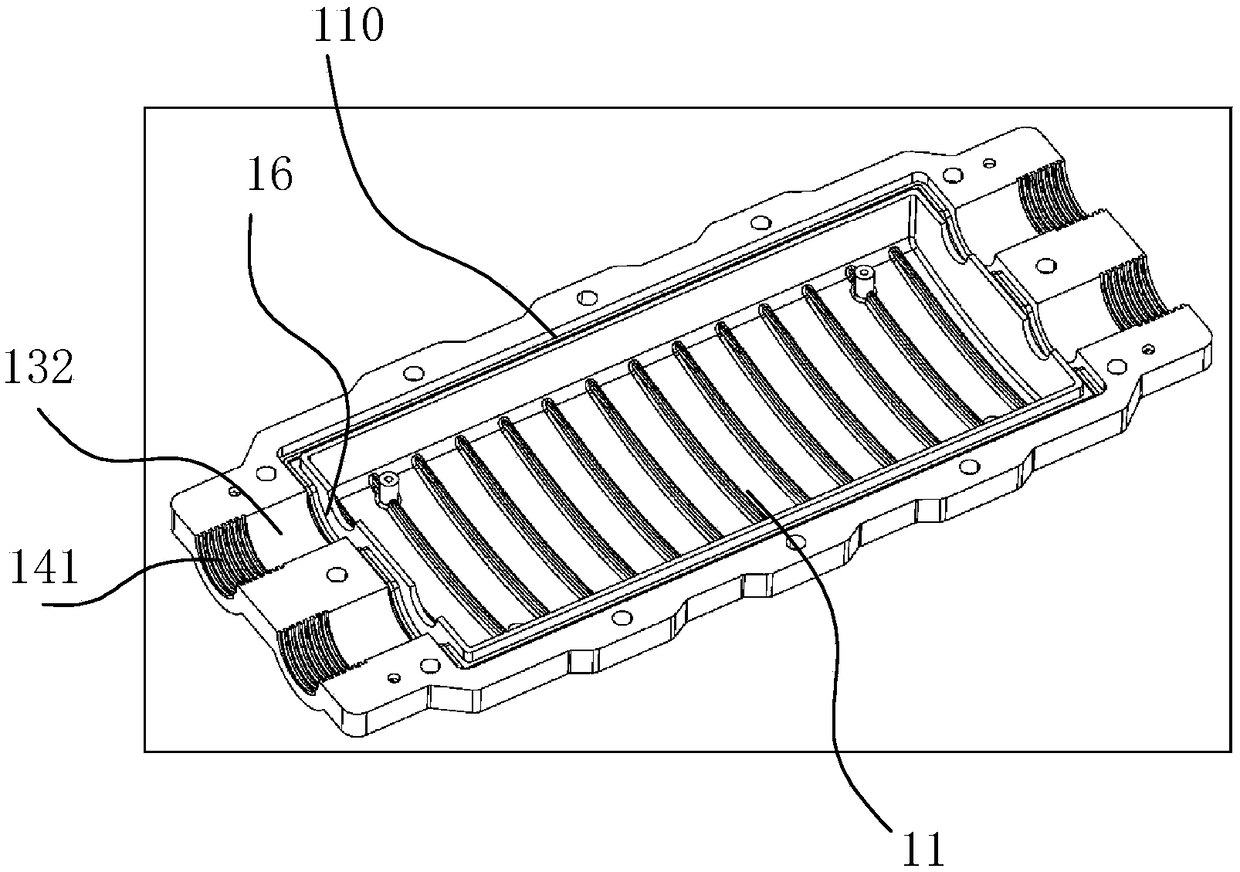

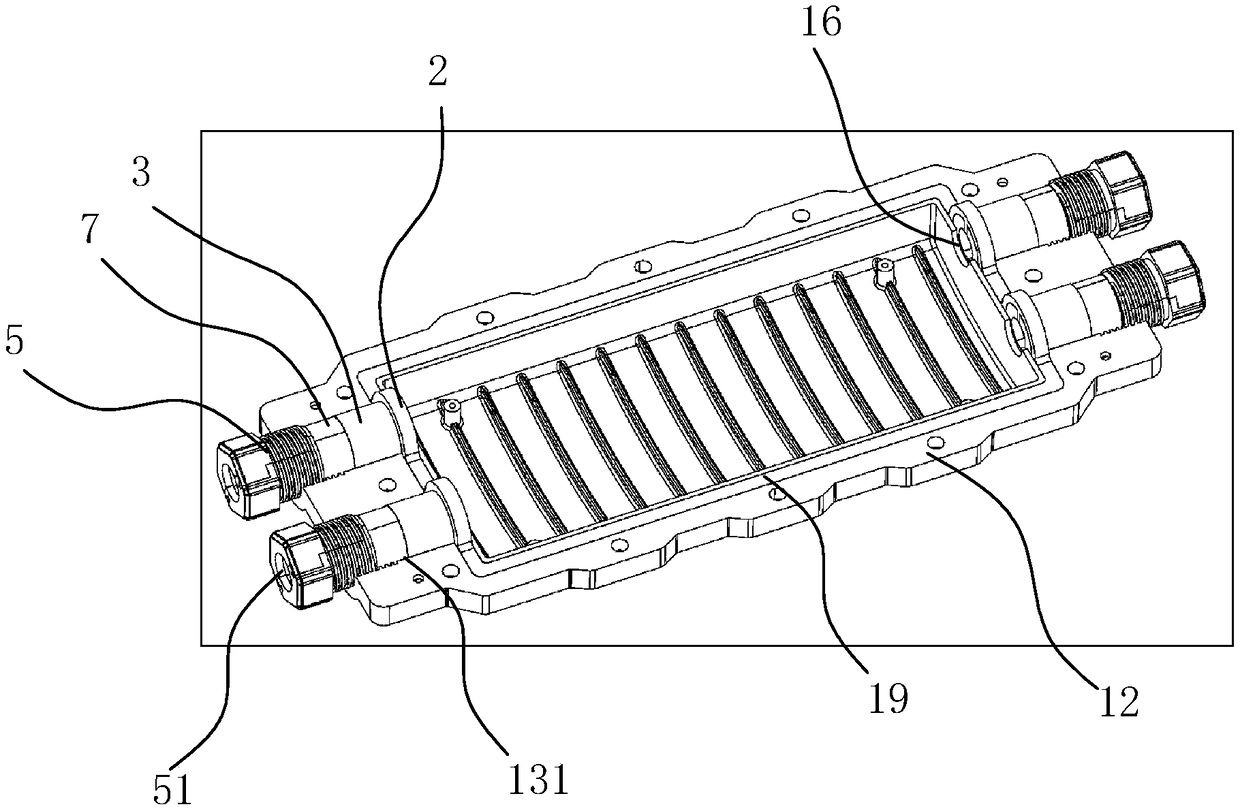

[0071] see Figure 1-Figure 10 , the step-by-step sealing structure of the optical cable splice box in this embodiment includes an upper box body 11 and a lower box body 12, the optical cable splice box has an optical cable embedding hole for passing through the optical cable, and the optical cable embedding hole is from the inside to the outside A retaining ring 2, an elastic sealing ring 3, an extruded module and an extruded part are arranged in sequence, and the retaining ring 2, the elastic sealing ring, the extruded module 7 and the extruded part all have perforations for passing through the optical cable, and the retaining ring 2 is fixed At the inner end of the fiber optic cable embedding hole, the extruding piece is pressed against one end of the extrusion module 7, and the other end of the extrusion module 7 is abutted against one end of the elastic sealing ring 3, and the function of the extrusion piece is to longitudinally squeeze the elastic seal ring, so that the ...

Embodiment 2

[0083] see Figure 11-Figure 23 , the step-by-step sealing structure of the optical cable splice box in this embodiment includes an upper box body 11 and a lower box body 12, the optical cable splice box has an optical cable embedding hole for passing through the optical cable, and the optical cable embedding hole is from the inside to the outside A retaining ring 2, an elastic sealing ring 3, an extruded module 7 and an extruded part are arranged in sequence, and the retaining ring 2, the elastic sealing ring, the extruded module 7 and the extruded part all have perforations for passing through the optical cable, and the retaining ring 2 It is fixed at the inner end of the optical cable embedding hole, the extruding part is against one end of the extruding module 7, and the other end of the extruding module 7 is against one end of the elastic sealing ring 3, and the function of the extruding part is to longitudinally squeeze the elastic The sealing ring makes the elastic seal...

Embodiment 3

[0096] see Figure 24-Figure 34 , the step-by-step sealing structure of the optical cable splice box in this embodiment includes an upper box body 11 and a lower box body 12, the optical cable splice box has an optical cable embedding hole for passing through the optical cable, and the optical cable embedding hole is from the inside to the outside A retaining ring 2, an elastic sealing ring 3, an extruded module 7 and an extruded part are arranged in sequence, and the retaining ring 2, the elastic sealing ring, the extruded module 7 and the extruded part all have perforations for passing through the optical cable, and the retaining ring 2 It is fixed at the inner end of the optical cable embedding hole, the extruding part is against one end of the extruding module 7, and the other end of the extruding module 7 is against one end of the elastic sealing ring 3, and the function of the extruding part is to longitudinally squeeze the elastic The sealing ring makes the elastic seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com