Method and measuring arrangement for monitoring a manufacturing process of a modular voltage source

A technology of production process and measuring device, applied in the direction of measuring device, capacitance measurement, measuring electricity, etc., can solve the problems of premature identification of assembly errors and insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

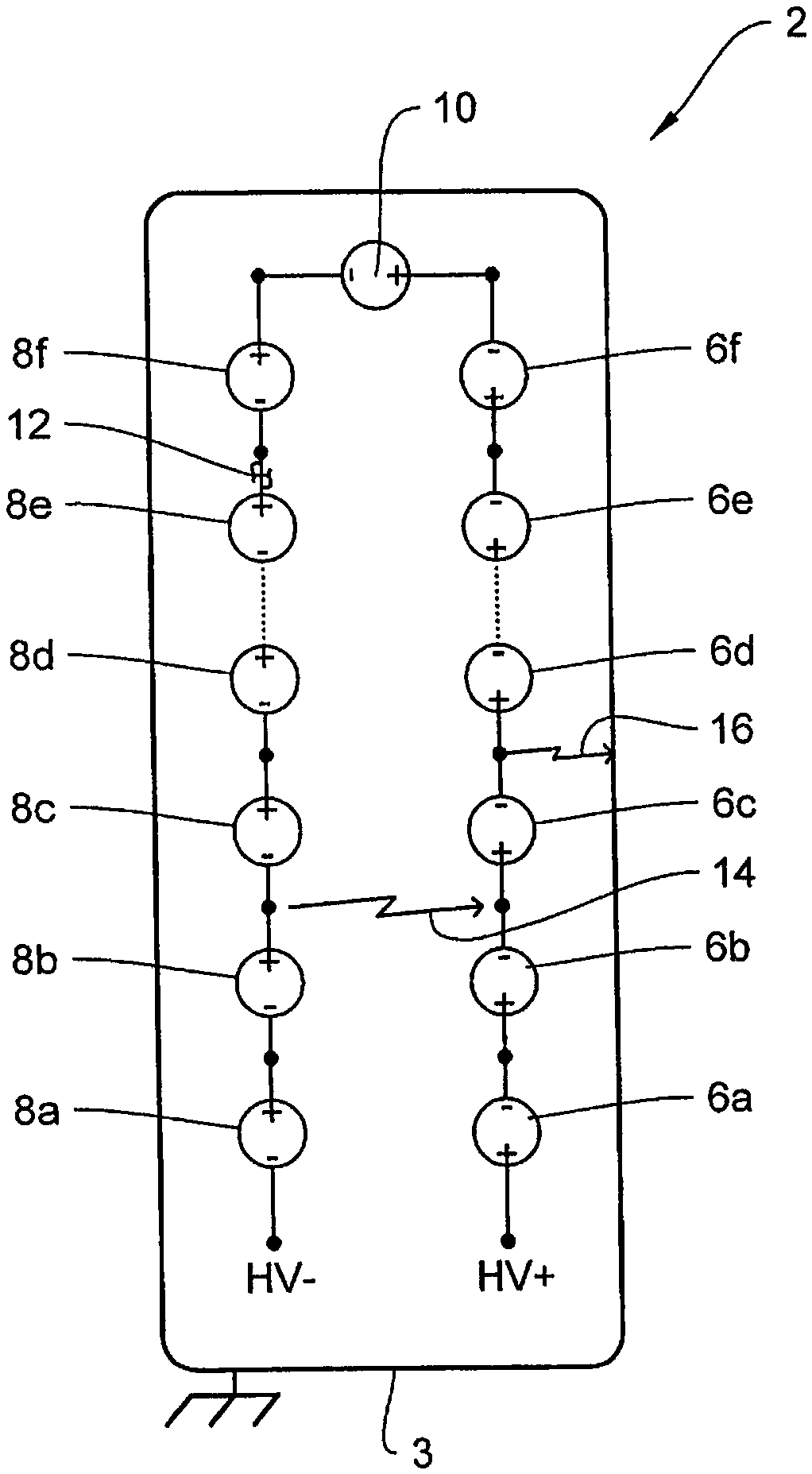

[0091] exist figure 1 In , the production process, which is based on the method according to the invention and the use of the measuring device according to the invention, is firstly explained by means of the example of a HV battery of modular design.

[0092] The HV battery is shown as a voltage source 2 consisting of modules 6 a to 6 f , 8 a to 8 f , 10 together with a housing 3 arranged in two partial strings 4 a , 4 b of modules. In general, any number of modules 6a to 6f, 8a to 8f, 10 can be built to form a first partial string 4a and a second partial string 4b of modules when applying the method, said first partial string 4a and said second partial string The string 4b can have a plurality of modules different from each other, as long as this is technically appropriate and seems feasible. In this regard, the invention also includes asymmetric designs of the two partial strings 4a, 4b of modules as well as designs in which only one partial string (4a, 4b) of modules is bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com