Novel double-cylinder air pump

A double-cylinder air pump, a new type of technology, applied in the direction of pumps, piston pumps, pump components, etc., can solve the problems of long inflation time, small inflation volume, poor stability, etc., to achieve the effect of reducing weight, overcoming poor stability and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

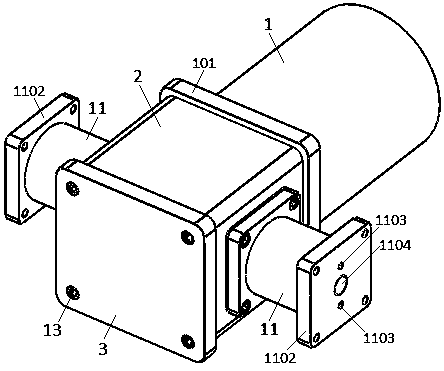

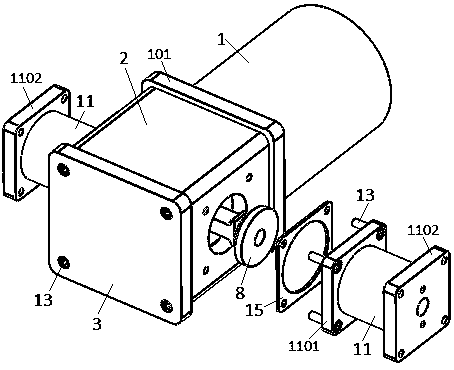

[0053] A new double-cylinder air pump of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. In terms of direction description, the assembly position of the front end cover is the front, the assembly position of the rear end cover is the rear, and the assembly position of the cylinder is the left and right direction. .

[0054]A new double-cylinder air pump is characterized in that it includes a motor 1, a housing 2, a front cover 3, a cam 4, a slider 5, a slider sleeve 6, a connecting rod 7, a piston 8, a U-shaped locking plate 9, and a guide post 10. Cylinder 11, sheet 12, screw 13, front and rear sealing sheets 14, left and right sealing sheets 15, small screws 16.

[0055] On the casing of the motor 1, a cuboid rear end cover 101 is provided on the end face of the motor shaft 102 side; an annular groove is provided on the front elevation of the rear end cover 101, and the groove is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com