Onshore integrated prefabricated bearing platform and production and mounting method thereof

A technology of prefabricated caps and installation methods, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., and can solve problems such as mold running, noise pollution in the surrounding environment, easy loss of brackets, formwork fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

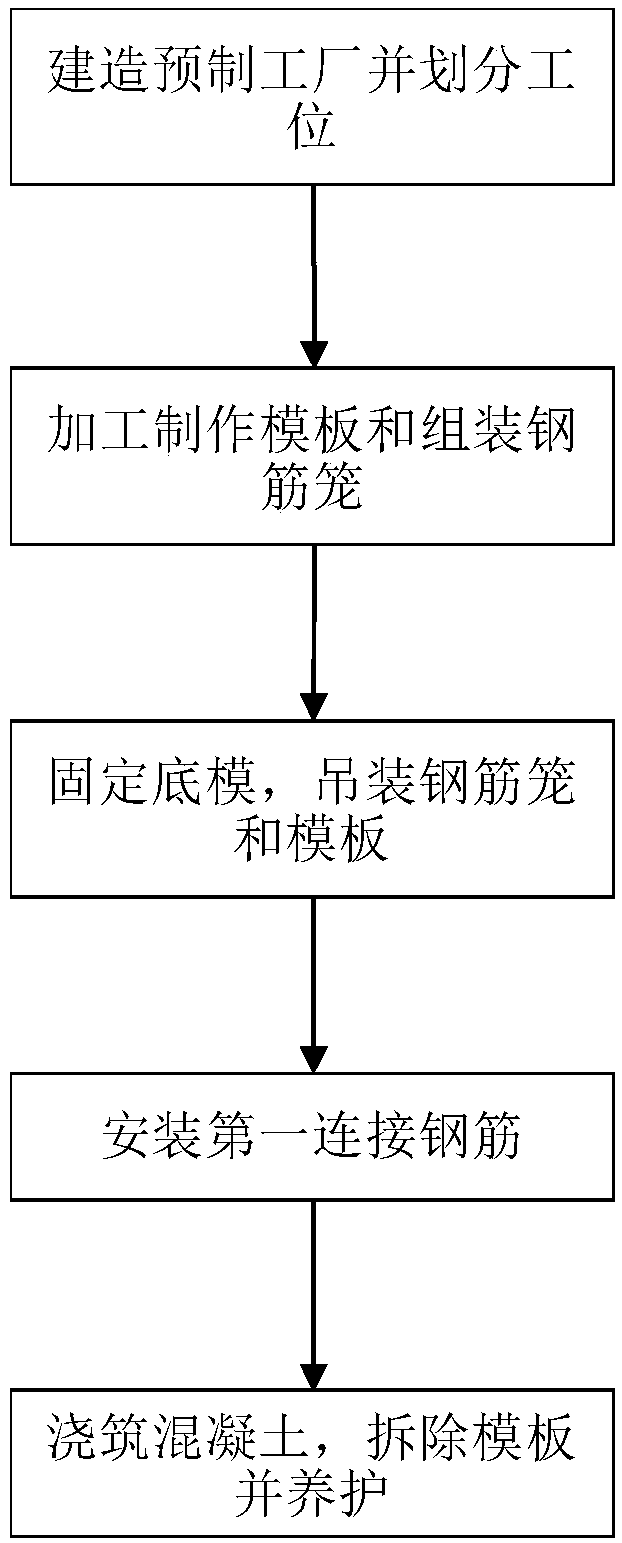

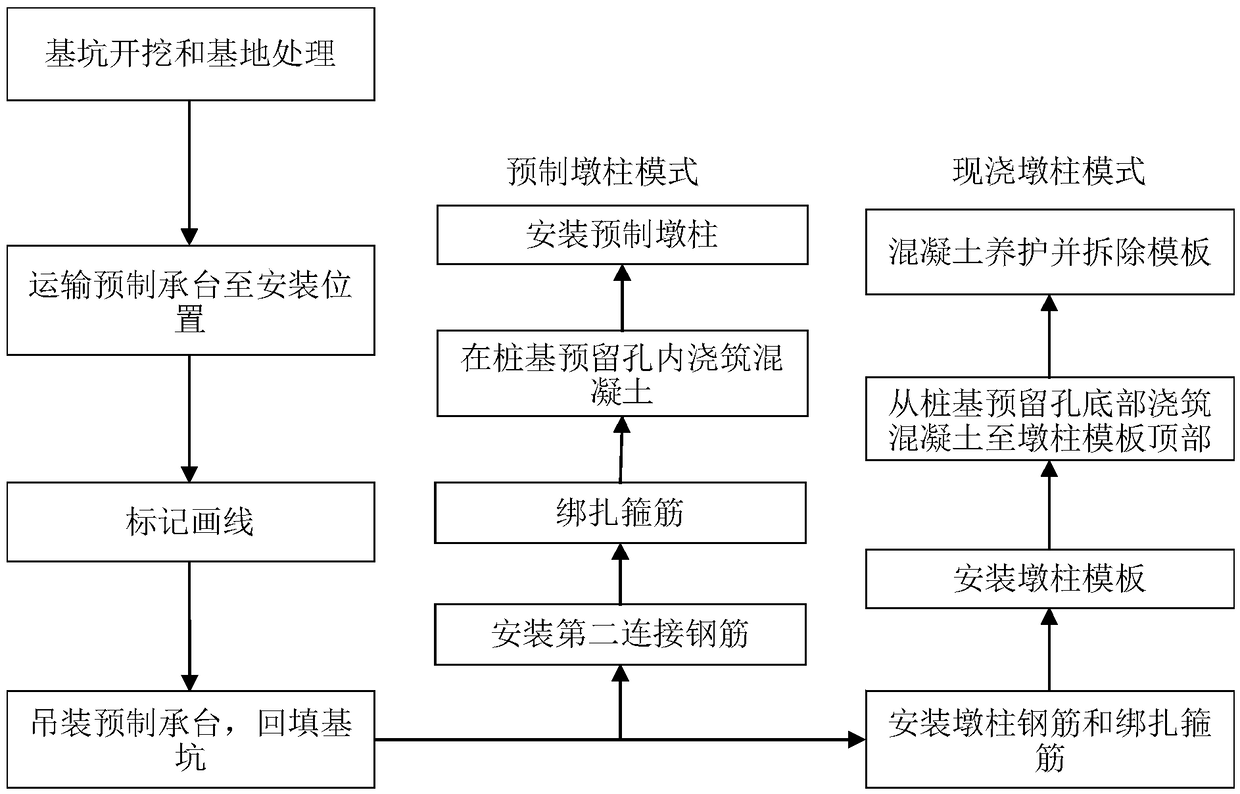

Method used

Image

Examples

Embodiment Construction

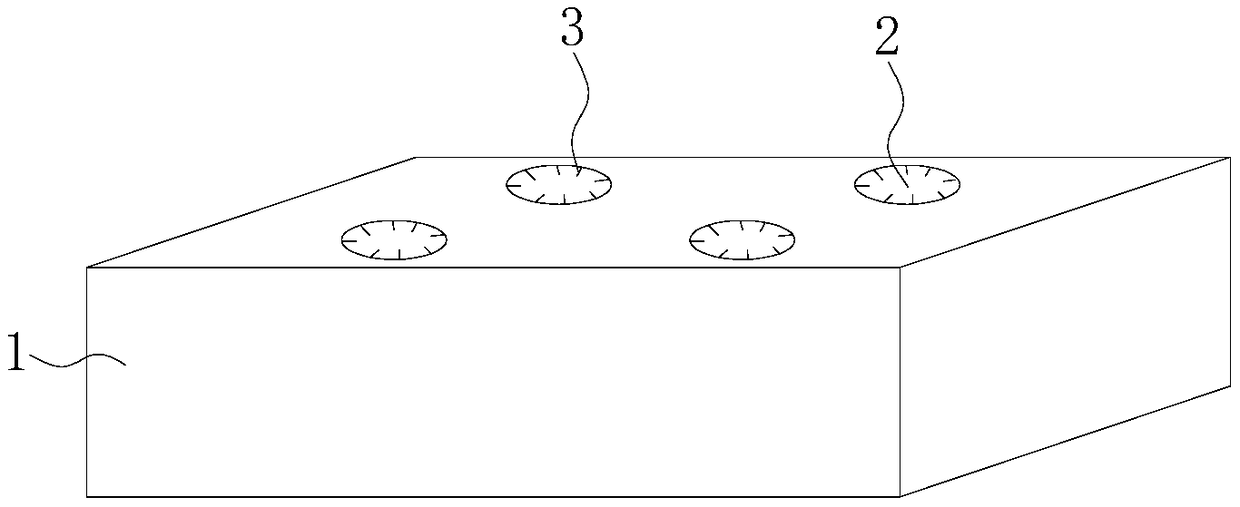

[0033] refer to Figure 1 to Figure 8 , the present invention is a land-based integral prefabricated cap, characterized in that: it includes a prefabricated cap 1, the prefabricated cap 1 is provided with a cap reinforcement cage and a number of pile foundation reserved holes 2, and the reserved holes around the pile foundation 2. Reinforcing reinforcement cages 5 with reserved holes for the pile foundation are provided, and a number of first connecting reinforcement bars 3 passing through the inner wall of the reserved holes 2 for the pile foundation are provided. In the reserved hole 2 of the pile foundation.

[0034] This onshore integral prefabricated cap platform prefabricates the reinforced concrete cap platform first, and then lifts and installs it in place. It transfers most of the work of the traditional cap platform construction to the factory, which can improve the quality of concrete pouring and save raw materials and labor. The labor force is reduced, and the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com